Cutoff Saw Creates Blanks from Superalloy in Seconds

Northern A-1 Services needed to quickly dry-saw Inconel barstock for a casting process. Kalamazoo Industries’ cutoff saw with true wheel oscillation system helped the shop solve this problem.

The superalloy Inconel is valued for its strength and heat resistance, but these properties also make it difficult to machine. Northern A-1 Services, a recycling company with facilities throughout Northern and Western Michigan and in Pennsylvania, needed to saw Inconel barstock without using coolant to create casting charges on a just-in-time (JIT) delivery schedule for an aerospace customer. Given the time constraints—and sawing operation in general—the company realized it would need a better cutoff saw than what it had.

As a result, the company turned to Kalamazoo Industries of Kalamazoo, Michigan, to develop a cutoff saw capable of dry-cutting Inconel barstock in a matter of seconds rather than minutes. As it turns out, the 12-feet-tall cutoff saw Kalamazoo Industries delivered with a 75-hp motor and 36-inch-diameter abrasive wheel turned a challenging operation into a repeating source of job-shop-type revenue for the recycling company.

Northern A-1 Services provides transportation and disposal of all forms of recycled materials, be they hazardous or non-hazardous. The company also has experience cutting many kinds of metals, including Inconel. For the aforementioned customer in the aerospace industry, it had also used its high-pressure waterjet capabilities to clean castings, and subsequently was asked to cut the gates and risers off those castings, too.

Pleased with Northern A-1 Services’ work and turnaround time, the aerospace company next offered it a contract to cut Inconel barstock into billets for casting charges on a JIT basis. For this job, Northern A-1 Services would receive 3-, 5- or 7.5-inch-diameter Inconel barstock, depending on the size and number of charges required, to saw to precise lengths.

The company needed to dry-cut the barstock to avoid any chance of contamination during the casting process, as even trace amounts of coolant could potentially alter the material’s properties during casting. Dry sawing, however, ran the risk of scorching the material and adversely altering the material’s metallurgical composition. If dry cutting a superalloy sounds too easy, the JIT timetable meant that the company had to cut through a very challenging alloy as fast as possible.

As the facility and operations manager in Whitehall, Michigan, Brian Balon ran the math. He realized that the company’s standard abrasive cutoff saw could not make the hundreds of cuts required, even with a wheel formulated for Inconel. Moreover, the time required to make these cuts would never fit into the requisite delivery timetable. Therefore, he turned to Kalamazoo Industries and issued a challenge: Build a cutoff saw that can cut through 7.5-inch-diameter Inconel barstock in less than one minute without coolant.

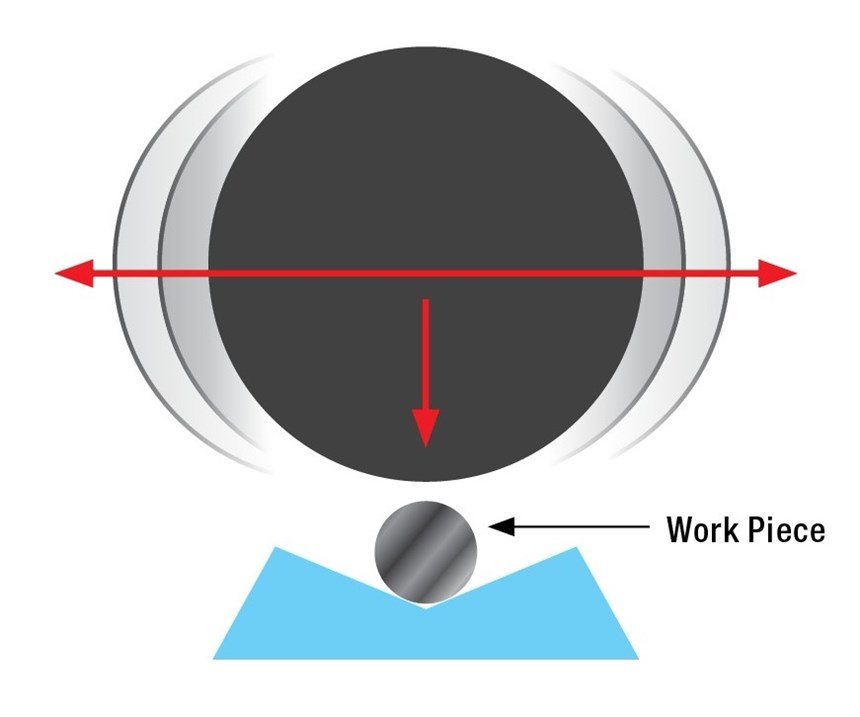

The Kalamazoo Industries team first determined that a 36-inch-diameter abrasive wheel specifically formulated for Inconel would be necessary. The formulations of this wheel are proprietary, but harder materials such as Inconel often necessitate softer wheels so that the material is constantly exposed to fresh, sharp cutting edges. Kalamazoo Industries also redesigned the oscillation system for its standard K36 cutoff saw. Rather than using a cam-driven oscillation system that feeds the saw wheel only vertically down into the material, the company created a “true oscillation” system that uses a rail to simultaneously feed the wheel horizontally. The company says this system creates an arcing motion that provides a greater arc of contact with the workpiece material that can enable faster cutting with longer wheel life. The stroke and speed of the oscillation depends on the material type and size. The machine also features a heavy base for improved rigidity as well as a 75-hp motor, increasing the speed of the saw to more effectively disperse heat and prevent scorching.

Kalamazoo Industries invited Mr. Balon to preview the machine prior to shipping, and the results checked every box. The saw could cut through 3-inch-diameter Inconel barstock in 7 seconds, 5-inch-diameter barstock in 15 seconds and 7.5-inch-diameter barstock in 29 seconds, all satisfying the JIT delivery requirements.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)