Doing More with a Live-Tool Lathe

A tool design improved the milling capability of a CNC turning center.

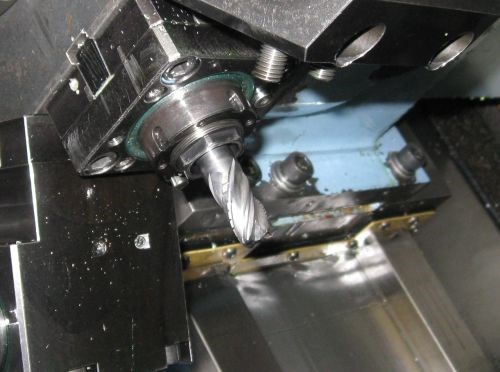

Owner Robert Johnson says the shop solved the problem with an end mill that cuts with less force. The four-flute Sasquatch tool from Gorilla Mill includes a roughing design on two of the flutes that shreds the material. The other two flutes are finishing edges that cut at a slightly larger diameter. In effect, the roughing flutes break up the material and the finishing flutes clean up these passes. With this tool design, Mr. Johnson says the shop can make the cut on the stainless steel part with less feed pressure. The more stable cutting extends the range of work he can do on one of his more versatile machines.

This slot in stainless is hard to produce on a compact live-tool lathe.

The shop milled the slot effectively using this cutter that combines roughing and finishing flutes.

Related Content

-

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

-

Choosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

-

Widia Introduces Solid End Mill for Shoulder and Side Milling

The WCE solid end milling series features a five-flute geometry specifically designed for optimal performance when shoulder milling and side milling carbon, stainless steel and cast iron.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)