Driveline Design for Superior Gears

New software is designed to deliver increased innovation, faster time to market and improved product quality for ground vehicle, wind turbine and geared transmission manufacturers.

The variety of transmissions available in the market today has grown exponentially in the last 15 years, all while increasing in complexity. The result is that we are now dealing with a varied number of transmission types including manual, conventional automatic, automated manual, dual clutch, continuously variable, split power and pure EV.

The variety of transmissions available in the market today has grown exponentially in the last 15 years, all while increasing in complexity. The result is that we are now dealing with a varied number of transmission types including manual, conventional automatic, automated manual, dual clutch, continuously variable, split power and pure EV.

Integrated Elements

Until very recently, automotive vehicle manufacturers largely had two types of transmission to choose from: planetary automatic with torque converter or conventional manual. Today, however, the volume of choices available demonstrates the changes seen across the industry.

This is also illustrated by the many different types of vehicles now being manufactured for the market. And not just conventional vehicles, but also all electric and hybrid vehicles, with each type needing different driveline architectures.

The traditional development process involved designing a transmission in isolation from the engine and the rest of the powertrain and vehicle. However, this is changing, with the limitations and complications of this method becoming more widely recognized, and the continuous drive among manufacturers and designers to deliver optimal efficiency at reduced weight and cost.

New powertrains feature close integration of elements like the prime mover, recovery systems and the gearbox, and also rely on highly sophisticated control systems. This is to ensure that the best degree of efficiency and performance is delivered at all times. Manufacturers are under increased pressure to create powertrains that are brand new, different from and better than the last version—a proposition that’s made more complex by the need to integrate brand elements, differentiate within the market and do it all on a shorter timescale. Engineering teams are on deadline, and the development process needs to be more efficient and fast-paced than ever before.

Driveline Developments

Until now, the use of computer-aided engineering (CAE) has been the most common way to develop drivelines. This process involves components and subsystems designed in isolation by silos within the organization that lean toward proven component-level analysis tools. While these are highly advanced tools that enable users to extract very reliable and accurate data, they are still presenting data that is collected without consideration of the whole system.

While this can produce components that all work very well individually, putting them together without prior consideration of the entire system can create designs that don’t work, leading to issues in the driveline that are difficult and expensive to correct.

One common problem, for example, is powertrain noise and vibration issues that go undetected until the first hardware prototypes are tested, which means having to go back to the beginning with design.

Alongside this is the problem of transferring data between different design and analysis tools, and doing so quickly and without error. Even basic design changes can be a bottleneck, with weeks going through various departments. They also require manual updating of models, which can leave the design prone to error and further slow the process. Unsurprisingly, this can be a barrier to organizations trying to innovate and create cost-effective designs. Anything that can speed up the process to help bring sophisticated new powertrains to the market quicker is worthy of consideration.

Sadly, no single toolset exists that can design every powertrain from concept through manufacture. This is exacerbated by the fact that manufacturers tend to stick to what they know without exploring alternatives. This presents a challenge for the industry when it comes to using CAE tools—including the need for product design to be right the first time, holistic transmission and powertrain development and efficient data exchange to enable collaborative work methods.

Romax Technology—the U.K.-based gear software designer with offices in Boulder, Colorado, and Troy, Michigan—is looking to address this by improving the driveline concept design process in order to facilitate collaboration through the entire development process.

Systemic Approach

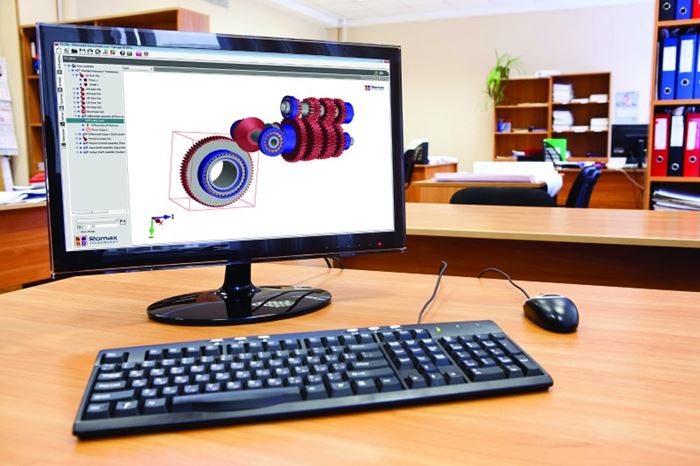

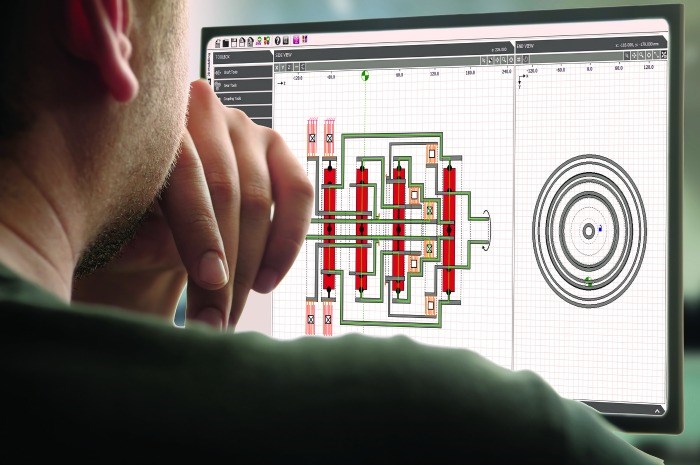

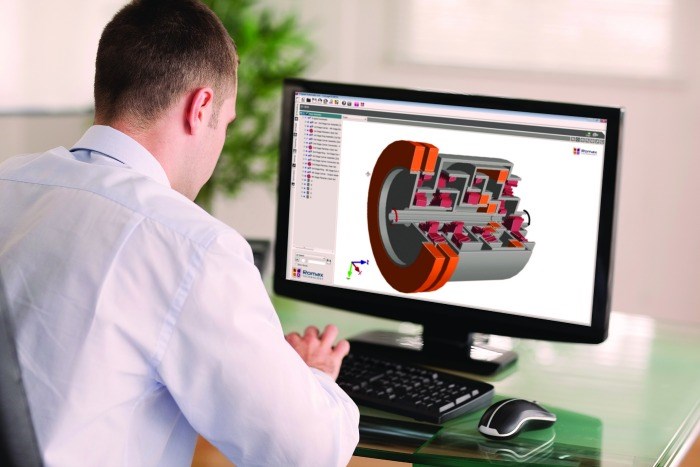

RomaxDesigner is a virtual product development and simulation environment for the design, analysis, and noise, vibration and harshness (NVH) exploration of the complete transmission—gearboxes, bearings, drivetrains and all components. It can also reduce the number and length of design cycles by considering all system effects in one transmission model. From the initial concept stages, component lives are calculated providing a fast method for system development.

Concept software can deliver increased innovation, faster time to market and improved quality with intelligent, rapid concept design and analysis capability for ground vehicle, wind turbine and geared transmission manufacturers. It also brings easy-to-use and sophisticated modeling and calculation capability to the conceptual design stage of driveline development.

CAD Fusion enables the seamless movement of data between systems in the driveline design and development process, from planning through to manufacturing, by removing the need for repetitive, low-value modeling, and reducing user errors. It delivers an intelligent approach to software interoperability by leveraging the best capabilities of CAD, gear design and Romax CAE applications.

Dynamic Fusion significantly improves the speed and accuracy of component, gearbox and driveline analysis using multi-body dynamic (MBD) software, a key tool in solving driveline dynamic problems (noise, vibration, etc.). In a typical design process, models need to be created from scratch or data needs to be translated from CAE and CAD systems into a separate MBD model created specifically for each of the failure modes required. This can take significant time, can be expensive and lose much of the engineering intelligence of the design process. Dynamic Fusion solves these key challenges by enabling MBD users to import design data directly from a RomaxDesigner or Concept parametric model.

Essential Efficiencies

For manufacturers looking to lead the way in driveline development, efficient product development processes that emphasize the importance of a right-first-time approach and collaborative working will be essential. The aim is to always have the right software tools in place to avoid wasting valuable time.

Learn More:

Romax Technology, call 303-351-5418 or visit romaxtech.com

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)