ERP Captures Process Know-How Before it Retires

Sponsored ContentAs shops struggle to overcome the skills gap, ERP systems can improve the onboarding process and help document processes as skilled workers retire.

Share

Read Next

Too many shops grind to a halt the moment that one employee goes on vacation. You know the one: the person who knows every machine inside and out, who spends half the day fixing problems for other people, but still manages to finish their own daily tasks. They become vital to the productivity of the machine shop.

Skilled workers are invaluable to a machine shop, and it is important to take the time to document their process knowledge for the continued success of your business.

When working on a difficult part, the go-to milling expert has seen which approaches work and can dramatically reduce the time needed to develop the proper process to machine the part. Difficult materials? They know what cutters to use and how to adjust the feed rate. Inaccessible features? They know the best way to position to workpiece without losing rigidity. Through sheer competence, they become integral to the daily operations of the machine shop, and even short absences can feel like jamming gum in your gears.

Bad news: that person will retire one day.

A high proportion of skilled workers are reaching or have already reached retirement age, and shops need to learn how to continue functioning as employees retire or move on to other opportunities. A key factor in building up this resilience to change is documenting the knowledge that skilled employees have developed over time using software designed for recording manufacturing processes.

Tribal Knowledge Holds You Back

In a healthy shop, the old guard pass on their knowledge to incoming workers, who grow into skilled machinists in turn. Otherwise, the business risks losing that knowledge down the line.

Onboarding new employees can be a struggle for every shop, and the siloing of knowledge can keep new workers from growing and thriving in their position. Fortunately, there are digital tools that make it easier to document process knowledge.

However, not every skilled machinist is a skilled teacher, and it can be difficult to develop teaching tools when starting from scratch. Unfortunately, the failure to pass on knowledge prevents both the skilled machinist and the less experienced employees from growing. Newer employees can struggle to learn from notes scrawled in the margins of a paper traveler, and skilled machinists may lose out on moving into larger roles in the company because they are needed on the shop floor. This is the slow-acting poison of tribal knowledge: the often-inadvertent failure to share information across the workforce for the benefit of the entire shop.

Fortunately, tribal knowledge has a deceptively simple solution: document everything.

Naturally, I don’t mean machinists should fill out paper forms and file them away in an old cabinet destined to be ignored in a forgotten corner of the shop floor. That would accomplish nothing but wasting time.

Instead, take advantage of cutting-edge manufacturing ERP software that can make it easy to both document and retrieve process information for future use.

Building a Library of Skills

Modern manufacturing ERP systems can store setup and process instructions for both recurring jobs and specific features, making them easy to retrieve. This creates a library of institutional knowledge that both experienced and green employees can rely on to develop efficient processes for producing parts.

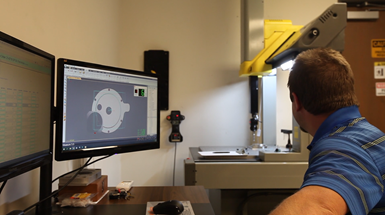

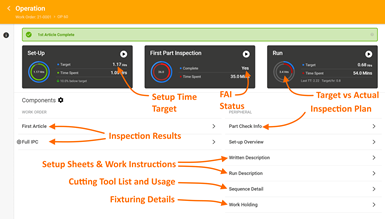

Proshop ERP enables shops to create digital travelers that make process information easily accessible at both the back office and shop floor. This makes setup easier and enables users to document process information.

Take ProShop’s ERP system: it enables shops to make all work instructions digital, which means making them easy to update and augment with explanatory notes, photos, videos and other media. Once the machinist develops a process, they can make the digital traveler available at a computer located at the proper machine cell. With this easy access, the operator can instantly see the specific requirements of the setup, including itemized lists of cutting tools and visual media that makes it much simpler to get the setup exactly right.

Proshop’s ERP system enables shops to keep track of process information through a digital traveler. In addition to making setup instructions simpler to follow, this enables shops to keep a library of process knowledge for future use.

The immediate benefit of this system is clear: it is much easier for the operator to follow the clear instructions through setting up the part. However, ProShop also stores this information in the cloud and makes this database of instructions easy to access. This makes documenting best practices for various processes much simpler as the explanatory notes, machining strategies, cutting tool preferences and more are all there to be referenced in future jobs with similar features. Need to mill small features in a deep pocket or produce threads in a difficult material? Refer to past jobs with ease. While paper travelers vary in their clarity and use as teaching material, the clarity of ProShop’s digital instructions enables newer employees to grow their machining knowledge base on the job.

By carefully documenting successful processes in the ERP system, shop owners can build a valuable trove of knowledge that adds to the total value of the shop.

Of course, gaining the full benefit from these digital tools takes efforts. Shops have to take the time to ensure that machinists document every step in the process and explain the reasoning behind choices. However, by committing to this process ProShop users can dramatically improve the onboarding process for new hires and create a clear path for green employees to develop the skills necessary to rise in the shop. More importantly, it enables the shop to better weather the loss of the experienced workers they depend on by making tribal knowledge accessible to everyone.

Speaking of Retirement

While many shops bemoan the loss of skilled labor, another group looking at retirement is the shop owner. Plenty of machinists who have struck it out on their own are thinking about retirement options, and selling the shop is often the way to go. However, getting a good price for your machine shop means demonstrating its value.

Again, ERP from Proshop can help. By carefully documenting successful processes in the ERP system, shop owners can build a valuable trove of knowledge that adds to the value of the shop’s capital equipment. It can dramatically benefit a seller to highlight not only its facilities and equipment, but also the accumulated experience of skilled machinists ready to aid any buyer in quickly profiting from their new purchase. Moreover, by creating a culture of shared knowledge, you build a more robust workforce that is more likely to continue working after you sell off the business.

Technical solutions like ProShop’s ERP software make it easier for shops to gain the full benefit of the people they employ. Rather than letting tribal knowledge to slow growth, this system enables shops to retain the skills of their employees and help greenhorns grow into skilled machinists in their own right. For more information, check out Proshoperp.com.