Share

It’s the daily fire drill at a job shop. Just after your weekly organization meeting you get a hot job from an important customer. You get the CAD file to your estimator and hope he can get to it in the next day. How soon can we ship? Prints in hand, you go to engineering to see how long it will take. If we clear the decks we can get it in 3 days, if we have the material. Someone has to walk out into the shop to check. Yes! We can do it, let’s go. Meanwhile, you’ve just guaranteed that two other jobs will be late, your overall shop utilization rate will fall unmeasurably, and you’ve angered several employees who are tired of dealing with changing priorities with incomplete information almost by the hour.

An integrated job shop management system can dramatically reduce the effort and confusion of working with paper-based management methods.

That’s just the price of juggling work in a job shop, right?

Not really. With the right kind of information automation you can harness the daily confusion that is the norm in many shops. These systems are typically called ERP, but there are major differences in their ability to serve a job shop. The right kind will combine estimating, scheduling, shop floor communications, even quality control, into a single integrated system. It will allow you to quote jobs quickly, with confidence, and clear visibility into real-time status of the shop floor to maximize efficiency while maintaining a high on-time delivery rate. And it will provide instant access to information all employees need to do their jobs – from estimators, to purchasing, to shop floor personnel, to shipping – without the need for routers or other manual communication and data collection methods.

ProShop is an ERP system like this that was originally developed in-house on the shop floor, by a job shop to serve the particular needs of its business. Over 22 years of continuous development it has been refined to deliver the functionality most important to a growing business. Watch ProShop’s take on how automation can solve a job shop’s information problem.

How Shop Information Automation Changes the Game

Most shops feel the pain of disorganization in missed deliveries and unhappy customers. What is much harder to recognize is the impact it has on utilization of equipment and people, and ultimately understanding which work is truly profitable and which is not. It also stymies growth. You can buy more productive machine tools, but until you fix the front office problem you can’t grow the business without adding people. You may get larger, but you won’t get more profitable.

The way to deal with this is with a system that automates and integrates your entire information ecosystem including:

- ERP – ERP stands for enterprise resource planning system and while that is extremely important, it alone is not enough. A basic system will get you beyond using spreadsheets to schedule the shop, but without real time updates of what’s actually happening on the shop floor, a schedule can become out of date almost as soon as it’s printed. And most ERPs don’t address the most important aspect of your shop, optimizing the actual manufacturing processes.

Nonetheless, job shop ERPs are a necessity for quoting, scheduling, job costing, inventory management and a variety of other functions. The best applications will draw from actual production histories to improve the speed and time of quoting and costing, enabling better customer responsiveness on quotes and production, and greater assurance you’ll actually make the margins you planned.

-

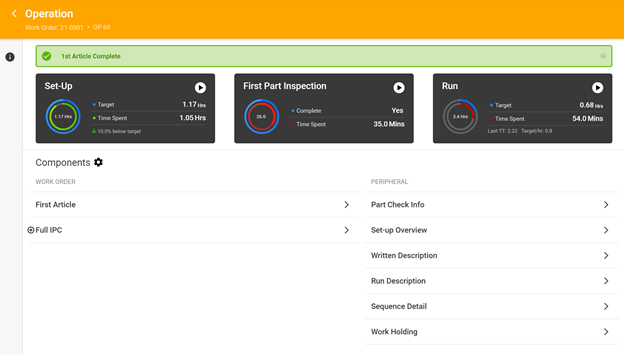

Manufacturing Execution System – MES systems have come a long way to help streamline the process of getting jobs to and through production. A fully integrated ERP/MES system provides real time feedback on how work is progressing relative to the plan. Just as important, it keeps track of all your people and equipment, providing instant visibility to the entire staff on all job requirements including machine availability, tooling, gaging and part program. And it provides access to detailed work instructions for each machine and job. Providing ready access to this information in the context of a dynamic scheduler can produce dramatic improvements in setup time, throughput and productivity.

Having all job information accessible can substantially reduce setup because operators can proactively prepare for the next job.

- Quality Managment System (QMS) – It’s more the rule than the exception that a job shop’s QMS stands alone, that is if a shop has one in the first place. It’s not just a matter of storing all your quality information in one place, though that is indeed useful. Having all quality information in a central repository can speed access to job requirements and required documents. It also provides the opportunity to store procedures, training content, compliance standards and necessary corrective actions. Having this data in one place makes operational requirements clear, facilitates instant audits, and can substantially reduce the time necessary to earn industry- and customer-specific certifications by as much as 50%.

Integration of your QMS with ERP allows instant access to a job’s quality status and documentation, enables all relevant quality information to be presented with the context of each job, and provides a singular process for preparing all internal job requirements and required documentation. It also provides a great tool for continuous improvement by providing visibility to the entire value chain, estimation to manufacturing to quality validation.

Case in Point

East Branch Engineering and Manufacturing (New Milford, CT), run by founder Paul Guidotti and his son Chris, is a job shop that specializes in high-precision, multi-axis milling and turning. With some 20 machines and 16 people on staff, East Branch has built a reputation for providing outstanding service and quality parts. The job shop was an experienced ERP user, but they continued to have problems with out-of-date travelers, blanket orders, certifications and disparate quality information.

Going to a fully integrated ERP system has had a dramatic impact on the business. According to the Guidottis, shortly after implementation employees began initiating work on jobs without being told. They could see the work queues at each machine and they could start preparing the jobs in advance. They also started taking pictures of all their setups and putting them in the system’s work instruction page for each part. This led to shorter setups and less time with spindles sitting idle.

Chris explains, “In our old system, job travelers would be put into a basket for purchasing material, etc. It was kind of a FIFO system and material would be ordered when we could get to it. It didn’t work well and we were always waiting for material or paying expedite fees to get it in. Now we can order the material very quickly with a click of a button, and we know the date we need it to support production, so it’s always here in advance. With this ability, we freed up the cost of a full time purchasing person and are still getting better results from the system.”

With ProShop all information associated with a job can be accessed from a single dashboard including setup instructions,required tooling and workholding, quality data as well as real-time job status.

Chris estimates that 10% of machines sat idle for 1-2 days per week in total waiting for material, workholding, gages, or tools when there was no easy way to manage and see such details. Previously, downtime also led to orders shipping late. About 75% of tooling and materials orders required expediting, and they paid quick ship premiums as well.

Within a year of implementing an integrated system, East Branch has seen:

- Increase in revenue of 18%

- $20,000 reduction in expediting fees

- $12,000 reduction in shipping fees

The new system allowed East Branch to fundamentally change the way it processes parts. “A machinist would set up the first machining operation, we’d run out the parts, then tear down the machine and set up for OP2. We had more frequent setups and the typical waste with batch processes,” Chris says. “Now because we can see that two or more operations are supposed to be flowed together, and it’s easy to document the setups with photos, we are setting up all the machining ops on the same machine and running a flow process for a longer time. It’s led to reduced overall setup times, higher spindle uptime, less scrap, and we can send partials ahead much easier than we could before.”

The East Branch supervisor of quality at the time gave a few words about his old shop that ran a paper based ERP, “I used to spend nearly 30 hours a week just dealing with paperwork. Uploading documents, downloading, editing and re-uploading, managing certs, and more. It was nearly a full- time job. We used to do our inspection using Excel. But with a fully functional QMS system that works. I can build an inspection plan much faster and I don’t have to link to any documents. It’s all right there in the system.”

ProShop has become the backbone of our company and has allowed us to make significant improvements in throughput, company organization, cost savings, and overall company profitability.

The takeaway: “ProShop has become the backbone of our company and has allowed us to make significant improvements in throughput, company organization, cost savings, and overall company profitability,” says Chris. “It has helped in so many ways that we never even considered before. We’ve been able to increase our on-time delivery rate to 99% and we’ve increased throughput without adding additional employees or machinery.” East Branch no longer needs a person dedicated to purchasing material yet has still been able to reduce lead times to customers.

Engaging Employees

With today’s difficult environment for recruiting and retaining skilled labor it’s hard to overemphasize the attention shops need to pay to engaging their employees in a positive way, and presenting their business as a great place to work. You want employees that care about professionalism, improvement, and helping build a world class company. Employees want to work in an environment that allows them to do their best every day, be efficient and productive. They don’t want to work in a state of confusion and continually re-solve previously solved problems.

Having your shop under control is critical to building the kind of environment employees want to work in. Says Chris Guidotti, “Showing the features and benefits of our ERP system during an interview shows the potential hire that we are committed to advancing the company. Showing your training pathways and a clear org chart can show an employee that the next steps in their career might be. For existing employees, they are able to better do their jobs with immediate access to up-to-date information, the ability to prepare earlier for the next job in cue, and not having to wait for someone to tell them what to do next.

For more information, please visit ProShopERP.com, email contact@proshoperp.com or call 1.800.990.4046.