Five Key Concepts Of Modular, Quick-Change Tooling

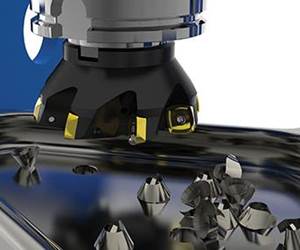

A tooling system consisting of interchangeable cutting units and standardized locking units has a lot to offer users of CNC machines, whether for turning, milling, or both on a turn mill. These guidelines will help you think clearly about how modular, quick-change tooling can benefit your shop.

A number of clear and powerful trends are impacting the metalworking industry. Customers expect higher quality but demand lower costs and quicker deliveries. Machine tools are becoming more capable and more flexible but are, in many cases, considerably more expensive. Lot sizes are becoming smaller. Competition is coming from around the globe.

In light of these and many other developments, shops and plants of all sizes are rethinking every aspect of their businesses. The ones that are adopting new strategies that leverage every technical advantage to the fullest are the ones most likely to succeed in this climate.

Modular, quick-change tooling is one of the tactical options many shops are exercising in their quests to stay on top of the competition. Modular, quick-change tooling systems first appeared about 10 or 12 years ago, but current trends and developments put a premium on the benefits these systems provide. In short, it's time to take a close, clear look at these systems.

The following five concepts sum up some of the most important aspects of modular, quick-change tooling. These points are drawn from material provided by Sandvik Coromant, one of the world's leading tooling companies and one that has been especially active in promoting intelligent applications of these tooling systems. If you keep these concepts in mind, your thinking about modular, quick-change tooling will be most enlightened, and rewarding, regardless of whose tooling system you might adopt.

1. Don't confuse "modular" and "quick-change."

These terms are not synonymous. Although all quick-change tooling systems are modular, not all modular tooling systems are necessarily quick-change.

Moreover, modularity and quick-change capability represent different values. For example, in a pure machining-center environment, modularity is more important than quick-change. Tools that can be changed easily into different configurations reduce tooling inventories and speed tool preparation in the toolroom. A wide range of tools can be put together from a limited number of interchangeable components.

Likewise, the availability of building-block extensions in many modular tooling systems enable long overhangs, difficult reaches and unusual cuts to be handled within the system. This economical versatility represents a gain in the machining center's capacity. Modular tooling lets it take on jobs that might otherwise be excluded, or it can perform more operations in a single setup. This increased capacity definitely improves the return on the capital invested in the machine as a whole.

Quick-change, on the other hand, is usually the leading value for lathe and turning center tooling. The number of positions on a turret or toolpost is limited, for one thing. In addition, the precision and repeatability of the coupling between the cutting unit and the clamping unit allow the position of the cutting edge to be known at all times. Setup times between batches is reduced. Trial cuts can be reduced or eliminated.

Modularity and quick change converge when it's a turn mill machine that requires tooling.

2. Ask these questions when considering modular, quick-change tooling.

Although the following list was drawn up by Sandvik in the context of turning operations, it is useful for milling environments as well. It gives the factors that indicate how beneficial quick-change features will be.

- How many setups will there be per shift? The more setups you do, the more quick-change tooling will help. If setups take up more than an hour per shift, quick-change tooling will probably save enough money in a year to pay for the tooling.

- How many tools changed per setup?

- How many inserts are indexed per shift? If you change edges more than every 15 minutes, quick-change tooling is worth serious consideration.

- How many trial cuts are made per shift? Today's quick-change tooling has the accuracy and repeatability to eliminate most trial cuts and gaging at the machine tool.

- What is the machine tool's hourly burden rate? The higher the hourly rate, the faster quick-change tooling will pay for itself. Today's machines often cost more but produce more, thus making the tool-changing time all the more costly.

- How many hours per year is the machine in operation? Many shops are shooting for 5,000 hours a year. The less time spent in setup or tool changing, the easier that goal becomes.

For machining centers, the value of modularity will be determined by these additional factors:

- How many mills and machining centers are in the shop?

- How many makes and models of machines are represented in the shop?

- How many different spindle tapers are involved?

- How many jobs require long reaches or special tools?

- On how many jobs do you use redundant tooling?

For all of these questions, the higher the number in your answer, the greater the value of modular tooling.

3. Modular, quick-change tooling can't be implemented in a vacuum.

Whether the modularity or the quick-change features or both are sought after, they will yield their full benefits only when accompanied by structural changes in the organization. In other words, to get the most out of modular, quick-change tooling, a shop may have to change its culture. It's been said that any system for quick-change is one-third hardware, one-third information, and one-third discipline.

For example, quick-change tooling promises to reduce setup time. But getting cutting tools ready is only one part of setup. Quick-change workholding fixtures, locating devices to re-establish fixture location, downloading of the machining programs, and automated handling of shop documentation are just a few of the other factors to consider.

Training is critical. Everyone needs to know and understand how modular, quick-change tooling works. Machine operators and toolroom personnel are obvious, but process engineers, NC programmers, estimators, schedulers, inspectors and managers must also be aware of what the new system implies for how they do their jobs. For instance, if new tooling can eliminate a secondary operation or an additional setup, process engineers must plan for it and estimators must factor it in.

Shop managers, some may be surprised to read, are the most likely to be affected by the discipline that a system of modular, quick-change tooling entails. Establishing new procedures often uncovers weaknesses in an organization. Poor channels of communication are the most likely problem areas to emerge. Moreover, the positive effects derived from implementing a new tooling system are quantifiable and measurable. Success demands that managers track these improvements and establish new benchmarks.

4. Consider tooling before a machine is purchased.

Tooling should be an integral part of the capital equipment buying decision. The choice of tooling at the time a new CNC machining center is purchased will have a significant effect on the return on that investment.

Choosing modular, quick-change tooling can reduce tooling costs over the life of the machine by 40 percent, Sandvik product specialists have pointed out. For a new CNC machining center or lathe, conventional tooling represents 5 to 10 percent of the total equipment purchase. For modular, quick-change tooling, a shop can expect to pay an additional 3 percent.

However, in the case of a $500,000 machining center, the extra $15,000 in the tooling budget will likely save $33,000 a year in tooling as long as the machine is in the shop. These savings are mostly in reduced costs for tooling inventory and elimination of specials. Of course, the more machines a shop has on its floor and the greater the variety of spindle tapers or styles, the greater the benefit of modular tooling.

A lathe, on the other hand, is likely to be 30 percent more productive with modular tooling compared to conventional tooling, in medium to short run work.

In short, tooling often determines the earning potential of a new machine as a whole. To maximize the tooling advantage, then, include tooling and toolholding as part of procurement planning.

5. Rethink speeds and feeds for modular, quick-change tooling.

At one time, implementing modular, quick-change tooling meant compromises in cutting rates or machining accuracies under certain circumstances. That is not necessarily the case at all today. Most newer systems offer repeatabilities in the 0.000078-inch range, qualifying them for the vast majority of milling and turning work that is available.

Depending on the manufacturer, some systems have the strength and rigidity to take cutting loads that meet or exceed those applied to solid tooling. Some modular, quick-change tooling systems are actually stronger than conventional tooling. This creates an opportunity to raise speeds and feeds and to boost material removal rates.

Keep in mind that quick-change capability reduces the penalty for frequent edge changing. In other words, in a tradeoff between extended edge life (which reduces tooling costs) and more parts, opt for more parts. Consumable tooling rarely accounts for more than 2 to 5 percent of total part costs. Reduced tooling costs gain relatively little, whereas increased machining capacity gains a lot. This becomes especially true of today's more expensive machine tools.

Sandvik recommends a good rule of thumb for optimizing productivity and edge life when modular, quick-change tooling is implemented: Push the insert edge with higher speeds and feeds until it fails after about 15 minutes of cutting time.

Stainless steels may be especially ripe for a healthy boost in cutting feeds and speeds. Many shops have never adjusted to advances in chipbreaker geometry and insert grades and so, they still run these materials at very conservative machining parameters. Don't let obsolete assumptions rob a new tooling system of its full potential.

A Force For Renewal

Change is good. It stirs things up. It brings out creativity and resourcefulness. It both generates and consumes human energy.

A transition to modular, quick-change tooling might well be the catalyst that leads to a shop-wide revitalization. Implementing a new approach to tooling exercises all of the skills and capabilities that make an organization strong and agile. The lessons in efficiency, teamwork, coordination and discipline that it teaches prime a shop for other, more challenging initiatives. It readies a shop for total quality management, ISO 9000 registration, vendor certification programs and the like.

It is important to look at all of the analyses and evaluations suggested by this discussion of modular, quick-change tooling. The numbers provide the best basis for decision making. But give some thought to what else there is to gain. Modular and quick-change can be read as flexible and fast.

It's not just your tooling that has to be that way.

Related Content

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreNew Modular Tool Options for Small Spindle Milling

Tooling options have been limited for small spindle milling applications. Now modular, indexable systems are available that provide broad flexibility to get the right cutter for the job with less inventory and at lower cost.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)