How to Practice Stage Two Thinking in Your Machine Shop

Responsible decision-making requires thinking beyond the initial benefits to consider how a change ripples throughout the machine shop’s operations and culture.

Don’t stop at simply considering the immediate or primary outcomes of a decision. Think about how those effects will ripple through your machine shop over time and what their implications may be.

In “Applied Economics: Thinking Beyond Stage One,” the economist Thomas Sowell argues that “stage one thinking” is when a decision-maker considers only the immediate result of an action without determining what happens next. An example of this might be a government’s decision to raise taxes, assuming that the only result would be increased revenue. What it may fail to factor in is the subsequent effect on the business environment, possible relocations or expansions elsewhere, or negative payroll implications. The net result may actually be a loss in revenue over time.

On the shop floor, stage one thinking could encompass hiring decisions, capital equipment purchases or strategic initiatives. Here are five areas in which I personally failed to look past stage one when I decided to purchase a machine shop, and what stage two thinking would’ve involved in each scenario.

Existing Customer Base

Stage One Thinking: Since I was familiar with the current customer base, I made some basic assumptions regarding the shop’s current workload. I thought the business had strong customer relationships, steady business and consistently profitable work.

Stage Two Thinking: If I had peeled the onion back one more layer, what would I have found? What market segments were these customers in? Were there long-term growth opportunities, or were these flash-in-the-pan moments we were taking advantage of? What was our average customer size? Was I working for large corporations with deep pockets and more work than I could provide, or was our customer base smaller, niche products that could rarely keep my machines busy?

When looking at a customer network, be sure to ask what customers fit the business best. What is the business set up to handle, and who might those customers be? Which customers don’t fit into the company strategy you’re trying to implement?

Workforce

Stage One Thinking: The business had several long-term employees and high retention rates, and most employees seemed happy with their jobs. There was a mix of older talent with the wisdom to train the younger employees.

Stage Two Thinking: Why were there so many long-term employees? Did they truly love their jobs, or had there been a lack of management that led to employee complacency? Were company policies and an employee handbook in place? Were all employees aware of them? Were company rules and expectations enforced when need be? What were the accepted norms at this company that might not be tolerated elsewhere?

When I purchased the business, I was impressed by several of the long-term employees, a few of them having been with the shop over 20 years. After taking ownership, I quickly realized that one of them should have been let go 20 years ago. I didn’t realize the long-standing management issues I was handed.

Equipment

Stage One Thinking: Yes, there were several aged pieces of equipment, but they did their job dependably and held tolerance. Our newer equipment kept the shop competitive and added to its capabilities. The company was using the current equipment to deliver quality products to customer specs.

Stage Two Thinking: How did changing technology affect our current equipment? How did the equipment handle our current mix of work? What maintenance should I expect in the coming years? Did I have the ability to grow with my current customer base with the same equipment? What impression did my shop floor give our customers?

In the ever-changing technology landscape, it is more important than ever to understand how your shop might look in five or 10 years. A decade-old machine tool may run all day, but if your machine memory and capabilities don’t match the machining speeds and feeds you can output, you’re only as good as your old equipment. Understand what investments may be necessary to stay competitive.

Process/Organization

Stage One Thinking: The business had an ERP system in place with good shopfloor organization and sound flow and execution from start to finish.

Stage Two Thinking: Was the ERP system being used to its full capabilities? What company metrics were being tracked, and was the information accurate? What was the continuous improvement history and culture within the business? Were there constant fires to put out or was there a drive for improvement?

When evaluating the processes and organization of your shop or potential purchase, it’s critical to understand what you are inheriting. From ERP reporting for better company communication to shopfloor metrics that drive employee performance, there may be great opportunities to improve quickly.

Technology

Stage One Thinking: The company was functioning as it should with limited internal issues. The business had a general understanding of how technology benefits the company.

Stage Two Thinking: How was the company using existing technology to improve or grow? What opportunities were visible that could streamline process or replace unnecessary labor? What investments were needed to get the most from the technology available?

From the front office to the shop floor, technology has improved or replaced what previously required human hands and hours of labor. How can the business offer the most to your employees while staying productive and profitable?

Taking the Next Step

The first step is to get a 10,000-foot view of the company. Next, identify areas that function and flow well. Identify areas that need upgrades and attention. Next, do some stage two thinking within each area that needs improvement. Diagnose the most pressing issues and produce and action plan.

About the Author

Jesse Schelitzche

Jesse Schelitzche is the owner of Imagineering Machine Inc. in Minneapolis, Minnesota. In addition to focusing on high-mix/low-volume machining in the medical device, aerospace and semiconductor markets, he also serves on the board of the Minnesota Precision Manufacturing Association (MPMA).

Related Content

Solve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

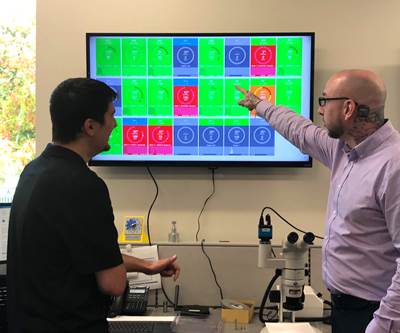

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreA Career at the Top Helps Rebuild a Job Shop

A new approach to management propels expansion into Swiss-type and multitasking machining work.

Read MoreRead Next

Communication Clears Machine Monitoring's Morale Hurdles

When pen-and-paper methods of tracking job efficiency left AccuRounds’ engineers and managers in the dark, the shop switched to MachineMetrics. But machine monitoring brought morale challenges along with it.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)