Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Share

Machine tool monitoring is not really just machine tool monitoring. It is organization monitoring — or should be. When the activity report from a machine tool monitoring system shows a particular machine being out of cycle for an unexpected stretch of time, the cause of that lost productivity typically is not the machine itself. Rather, the cause is found in some failing or shortfall in the organization around that machine: Some needed tool, work instruction, measurement or operator intervention was missing, and the disconnect prevented the job from proceeding. In theory, machine tool monitoring ought to reveal and provide a way to address opportunities for improvement such as these. But in practice, there is a big missing piece.

Adam Ellis saw this in his work with machining facilities that were seeking to improve efficiency by leveraging machine monitoring information. The missing piece is this: The machine tool monitoring system does not know what the machine is supposed to be doing in any moment it analyzes. As a result, there is nothing against which to reference the machine’s performance. This leads to the way machine monitoring output is generally used today — shop management looks at bar graphs after the fact and tries to solve the problems the graphing makes apparent.

But there is a different shop resource that does know what the machines ought to be doing. That is the enterprise resource planning (ERP) system. Can ERP and machine tool monitoring be brought together?

Yes, says Ellis. And arguably he should know. He has worked as an ERP consultant for 25 years.

The startup he co-founded and now leads is Harmoni. The company’s aim is to develop and market a product for closing the loop between machine tool monitoring and ERP for any and every CNC machine tool a shop might use. Providing for real-time evaluation of performance was the initial promise, but the system has proven effective for something even more powerful: assuring NC program revision control, and the correct assignment of programs and work instructions to every part. This latter set of benefits comes thanks to radio-frequency identification (RFID).

I spoke with Ellis recently about Harmoni’s system, which, among other things, seems poised to make the “Internet of Things” — a local version of it, at least — an everyday part of machine shop work.

The Harmoni device connecting the machine tool CNC with a shop’s ERP system. Control unit connection options seen at left. Another array of options including mini-USB is on the opposite edge. The antenna atop the unit is for radio frequency identification of people and parts near the machine. Photo: Harmoni.

The Harmoni system uses a physical device to make the connection between machine tool monitoring and ERP (and the operator, but more on that in a moment). The Harmoni device is a “Swiss army knife of machine tool connectivity,” Ellis says. No particular CNC functionality or protocol is needed to obtain information from a machine. Instead, the Harmoni device is rife with every possible connection type a CNC machine tool might provide, including very old machines. “If the only data available are the wires sending signals to the red/yellow/green light, then we can use just this much to get status information,” he says. The same Harmoni device then also links to the shop’s ERP system through connections the company provides. Once the loop is closed in this way, one possible result is real-time tracking of charging efficiency, in which the shop can see how much it is charging for the work of each machine tool compared with how much the machine is actually producing.

But the device’s awareness also extends to people and parts, and this is where its capabilities potentially promise to be even more transformative.

The Harmoni device is a human-machine interface (HMI; “Harmoni” derives from this). Its touch screen provides for work instructions as well as messaging within the organization. It is also a distributed numerical control (DNC) device, sending programs to the CNC. And it has radio frequency sensing, offering the ability to detect and identify RFID tags. This combination of features can bring shops a seemingly magical level of responsiveness.

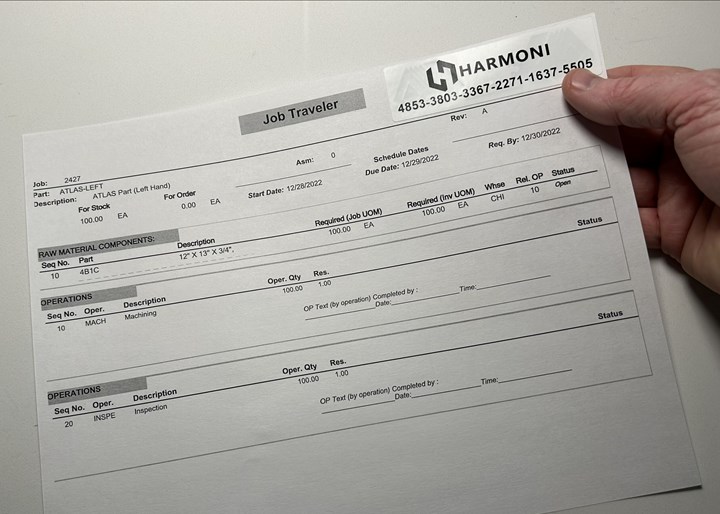

An RFID tag, seen here affixed to the upper right corner of a job traveler. Tags like this are cheap and can be liberally affixed to any person or object (such as a part or tool) that is valuable for the system to be able to sense. Photo: Harmoni.

The RFID tags are a notable element. Each tag is about 7 cents, says Ellis — cheap enough to be used liberally. “Place them on people, parts, fixtures, raw material — anything you care about,” he says. The effect, potentially, is a shop-wide awareness that provides for all the needed safeguards against costly error.

Imagine this, Ellis says: An employee approaches a machine tool. The Harmoni device identifies the employee and offers the option to clock in. The device knows what job that employee is supposed to be running on that machine at that moment. It offers the option to begin the operation at that machine and, if so, it sends this information to the ERP. It then presents this person with the work instructions appropriate to that job. It also loads the NC program — the correct NC program, automatically obtaining the most current revision. Then, the Harmoni device does a radio sweep to assure the correct fixture is in the machine, the correct material is being loaded, all the needed cutting tools are in the magazine, and maybe even that needed hand gages are within reach.

With these steps — performed instantaneously — the system automatically controls for, and avoids, what otherwise might be two dozen different opportunities for lost productivity or a costly error.

Can the system really work that reliably? And control the process that seamlessly? We will know soon. The first run of Harmoni devices has been sold to early-adopting shops, which presumably will soon put them to use.

The workforce implications could be the area of most profound impact. Those two dozen opportunities for error: Shops today rely on knowledgeable employees who are able to foresee and avoid these errors. The critical need for skilled labor in shops is in part a need for employees who can safely setup and oversee a machining process by guarding against all the different ways the process might go wrong. But in the future, employees with less skill and experience could be able to do more, running work at higher value without restriction or supervision. They will be able to do this if the network, the local Internet of Things, is effective at guaranteeing the process will perform correctly. This promise is valuable to say the least — and it might be realized in part by using accessories that cost 7 cents apiece.

Peter Zelinski writes about manufacturing technology and how it is changing. Find more of his work related to CNC machining and additive manufacturing. To suggest an article topic related to a success in your manufacturing facility or business, or a technology development you are close to, email him here.

Related Content

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreRead Next

Improving Workflows in Small Shops with Custom ERP

Small shops might not be ready for all of the functionality of an off-the-shelf ERP system, but modular, custom ERP programs can help improve workflow while providing the flexibility to change as shops grow.

Read More3 Reasons Machine Shops are Paying Attention to ERP

Awareness of people and the value of their efforts accounts for part of the reason why we are seeing enterprise resource planning being taken more seriously.

Read MoreOEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More