In-Machine Robot Provides Gantry System Alternative

Fortune International offers its VT series lathes with an integrated robot in place of a tailstock, a configuration that is said to significantly reduce part-changeover time compared with an external gantry robot.

An increasing number of shop owners are looking to automation to reduce idle time and keep their machines making chips and making money. To meet demand, robotics, bar feeders, pallet changers and other such equipment continue to evolve to reach new levels of efficiency.

But it doesn’t always take a major breakthrough to improve the effectiveness of automation. Fortune International, the exclusive North American distributor of Taichung Machinery Works, offers a series of slant-bed CNC lathes featuring an integrated, servo-controlled robot in place of a tailstock. Compared with more commonly used gantry robot systems, this seemingly simple development can nearly halve part change-over time while using less space on the shop floor, the company says.

The Somerset, New Jersey-based company offers five models of its Victor Taichung (VT) series lathes in this configuration. Seated on the slideways opposite the lathe spindle, the Easyway robot transfers parts between the chuck and an adjacent workpiece feeder. Because the robot replaces the tailstock, the cells are said to be most useful for large batches of small parts. The five models available with Easyway have chuck sizes ranging from 6 to 10 inches, and the robot can accommodate a maximum part weight of 6.6 pounds.

The lathe, robot and workpiece feeder are arranged in a single cell in order to occupy as little floor space as possible. In addition, keeping the robot inside the machine minimizes the distance it needs to travel between the chuck and workpiece feeder while eliminating the need to open and close the machine door for loading and unloading. According to the company, this results in a change-over time of 7 seconds, compared with 15 seconds for an external gantry robot. And because the door is always closed, oil mist is kept inside the machine, resulting in a cleaner shop environment.

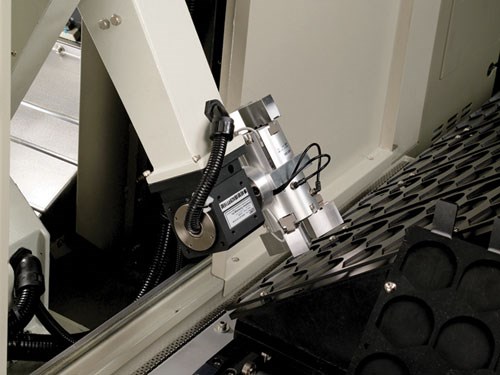

The three-axis, servomotor-driven robot features a dual gripper that rotates 180 degrees. This enables it to remove a finished part from the chuck, install a fresh workpiece and return the finished part to the workpiece feeder in a single operation. To program the robot, users must manually jog it from point to point and record the movements as motion commands. These commands are triggered from the lathe’s control when an operator starts the part program.

The workpiece feeder’s 16 rotating pallets, which are slanted to further reduce the cell’s footprint, are driven by a single servomotor and require manual loading and unloading. The pallets are available in three models that accommodate part diameters ranging from 0.4 inch to 4.72 inches. The model at the low end of that diameter range can hold 21 parts with 0.4- to 1.65-inch diameters, for a total of 336 parts in the entire feeder.

VT lathes are equipped with with Fanuc controls, spindle motors and servomotor systems as well as chip conveyors, electrical cabinet air conditioners and Kitagawa chucks. Available options include live tooling, subspindles and Y axes.

Related Content

-

Choosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.