Moving Toward Complete, Automated CAD/CAM Solutions

Best known for its machining software, UK-based Delcam is adding more software products for design and engineering. The company's explicit goal is to be 'a provider of complete, automated CAD/CAM solutions, taking complex shapes from concept to reality.

Share

Best known for its machining software, UK-based Delcam is adding more software products for design and engineering. The company's explicit goal is to be "a provider of complete, automated CAD/CAM solutions, taking complex shapes from concept to reality." Delcam is specifically targeting the needs of the toolmaker and subcontractor, that is, those involved in the manufacture of molds, dies, patterns, prototypes and small batches of complex 3D shapes. The appeal is to the mold shop (strong in machining) that needs to offer customers more design and engineering services, as well as to the aerospace or automotive corporation (strong in design) looking to bolster the in-house production of critical components.

The software is modular. One could build a system consisting entirely of Delcam modules, or one could use these modules to fill in the gaps amid a user's existing software applications.

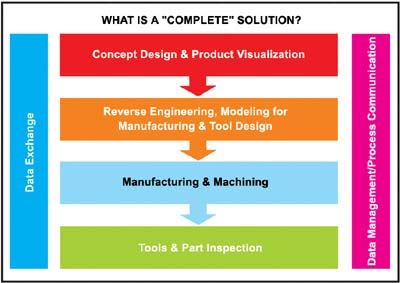

In Delcam's view, four big steps have to be taken to get a concept into reality. First, a user has to figure out what the part or end product is going to look like. Then the user has to figure out how to make that part in a mold, die or other tooling. Next, the user has to figure out how to actually make that mold, die or tooling. Finally, the user has to make sure these things are made correctly and that the parts produced in them are right. Figure 1 presents these steps in Delcam's own terms.

Two other sets of tools are needed to allow work to flow smoothly from step to step. One set (Data Exchange) makes sure that the data needed from step to step can be passed from step to step without delaying progress or creating new problems. The other set of tools (Data Management/Process Communication) makes sure that the people using the data can work together as a unified, effective team. In Figure 1, these sets of tools are shown as vertical integrators on either side of the four steps.

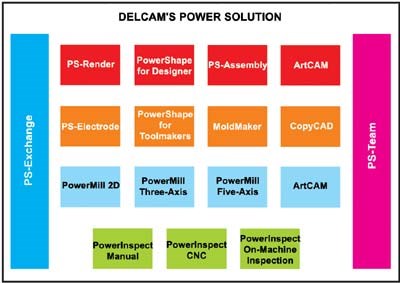

Delcam's software products can be sorted out according to this arrangement to show where they fit into the Big Picture of the complete solution. Figure 2 is the result.

Some of the modules appearing in the array are new; the rest contain significant enhancements currently available or soon to be released. Some highlights follow.

A concept called Total Modeling is being introduced in PowerShape 5, Delcam's premier CAD product. This concept is described as an extension of hybrid modelers that combine solid modeling and surface modeling. Total Modeling goes beyond surfaces and solids to include design techniques that are available in other Delcam design modules. CopyCAD, for example, provides reverse engineering and triangle modeling capabilities that are well suited for manipulating certain types of design features and geometry. ArtCAM, another new module, provides tools for relief modeling and decoration options.

Total Modeling allows the designer to mix and match among wireframe, triangle and surface data to define a solid. The designer can then present that whole design to other applications, such as PowerMill, for machining. Let's say the designer creates a honey jar in the shape of a teddy bear with a product logo wrapped across the figure's rounded belly. The bear shape might be developed from data scanned on a clay model in CopyCAD, while the logo was developed in ArtCAM. The shape and logo could then be combined and addressed as a single model for the purpose of designing a blow mold, ultimately to be machined or EDMed using tool paths and machining programs derived from this model. This simple example only hints at the power of the Total Modeling concept.

Likewise, the company's flagship CAM package, PowerMill, has been enhanced with new features and options. These enhancements are noteworthy because Delcam is anxious to preserve its reputation as a leading supplier of machining software, an emphasis that has not been diminished in the company's new thrust in the direction of design and engineering capability. For example, PowerMILL 4 includes enhancements in three key areas—high-efficiency roughing, high speed finishing and simultaneous five-axis machining. A knowledge-based machining option is also being introduced.

Delcam is using IMTS to showcase the breadth and coherency of its "complete solutions" approach to the production of complex shapes, where the automation of many design and machine programming functions is sure to attract considerable attention. One theme likely to emerge from product demos at the show is that automation is not "de-skilling," but a method to reduce routine work and thus leverage the creative talents of skilled employees. A newly revised compact disc covering high speed machining and five-axis machining also will be distributed at the show.

Related Content

AI Creates CAD Files From Scan Data

While 3D visual scanners are useful, converting a visual scan to a usable CAD file can be a time-consuming process. With generative AI, it may be much simpler and faster.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreCAM Copilots and the Next Digital Shift in American Machining

As AI reshapes programming and automation, Mastercam is betting on a future where human expertise and intelligent software evolve together on the shop floor. A conversation with Mastercam President Russ Bukowski.

Read More