Share

Ask any machine-shop person for a definition of “multitasking machine” and you’ll get as many answers as there are multitasking platforms and capabilities (which this piece will touch on). For purposes here, we’re talking about a machine that can perform both milling and turning operations.

Why Use a Multitasking Machine?

But, why do these machines continue to rise in popularity? It’s simple. They offer the opportunity for a part to be machined complete on one piece of equipment.

Traditionally, parts that might start on a lathe for turning work, for example, could then have to be taken to a mill to create prismatic features. That means, two machines must be set up and tended to. Parts with turning work complete must be transported to the mill. Those parts might have to be staged as work in process (WIP) waiting for the mill to become available (and scheduling can be tricky to efficiently coordinate machine availability). An accumulating number of setups and part repositioning can lead to error stacking. Multiple machines take up more floorspace and consume more energy.

In cases in which a multitasking machine can produce parts complete, these issues go away. That’s why there is increasing interest in multitasking machines to the point that these days, a basic two-axis lathe might only be found in the corner of a shop’s tool room.

Lathe + Milling Spindle

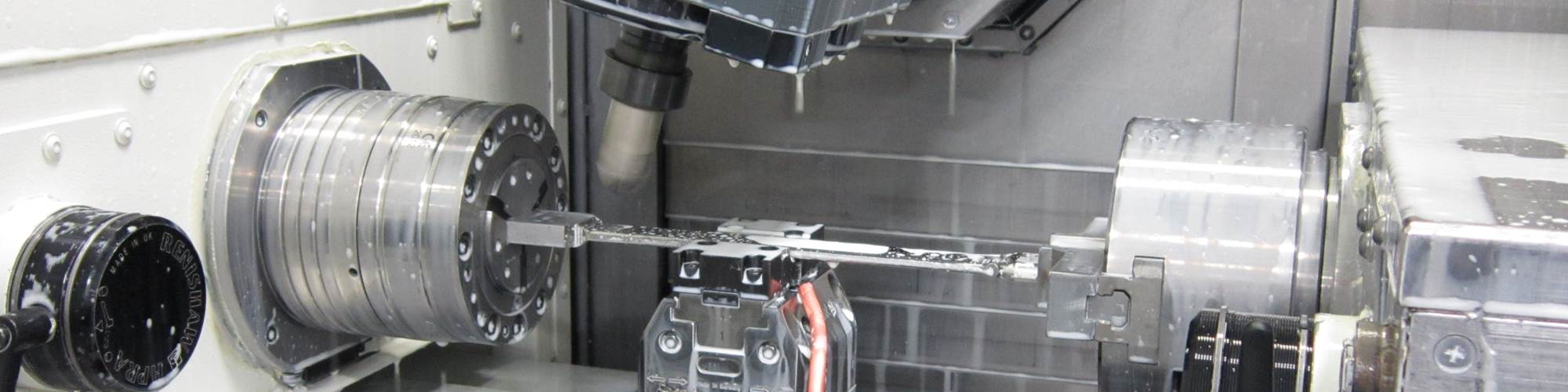

Many multitasking machines are based on a lathe design in which a milling spindle(s) has been added. The most basic is a turning center with live tooling. Live tooling simply refers to driven spindles that mount on a tool gang plate or turret that can be used for milling flats or drilling holes. Turning centers providing Y-axis movement extend milling capability for live tooling by enabling rotary cutters to machine across the spindle center line. Live-tool gear hobbing units are also available.

Plus, quick-change tooling enables faster setups of live and static tooling for new jobs, too.

Swiss-type Lathes

Live tooling is also found on Swiss-type lathes with their signature sliding headstock design. With this, barstock is gripped by a collet and fed through a guide bushing and past the stationary turning tool. The guide bushing provides support at the point of the cut making it well-suited for parts with high length-to-diameter ratios.

For a Swiss-type featuring a subspindle, once machining is completed on the main spindle, the workpiece can be cut from the barstock and turning, milling and drilling operations can be performed on the back side of the part as it is held in the subspindle. Swiss-types with B-axis milling spindles can perform five-axis work, extending their capabilities as shown in the video below.

Swiss-types are becoming more commonplace in traditional job shops, not just screw machine shops, to produce parts from relatively small-diameter barstock. However, the big advance for job shops that run bigger parts came when B-axis spindles having the torque and power to match dedicated milling machines as well as automatic toolchangers were added to turning center platforms. Sometimes, such “turn-mills” like the one shown below rarely perform turning. Just because parts might be created from cylindrical barstock, it doesn’t mean they can’t be prismatic once machined.

Multiple turret/multiple spindle turning centers offer the production advantages of performing operations concurrently on different spindles. Plus, operations can be performed simultaneously on one spindle. Examples as shown below include pinch turning, in which two static cutting tools are driven down the machine’s Z axis to increase material removal rate. Milling operations can also be performed at the same time on a part.

CNC Adds Flexibility

Since computer control has been added to multi-spindle and rotary transfer equipment, the new trend is introducing flexibility into these multitasking, high-production machining platforms. The idea is to enable equipment that can perform operations such as turning, milling, drilling, hobbing, polygon cutting and the like to pivot to producing other parts more easily. Again, quick-change tooling is an enabling technology to allow such equipment to shine as batch sizes shrink.

CAD/CAM technology has also vastly improved over the years to support various multitasking machine platforms. Some programming and control software is using AI to “build intelligence” into programming. A key part of this is the concept of creating a machine’s digital twin, whereby a digital replica of the entirety of a machining operation is created in a virtual environment. This technology not only offers the promise to prove-out programs offline to eliminate the potential of crashes for complex, multitasking machines, but to optimize tool paths to reduce cycle times. The challenge becomes with developing postprocessors for complicated machines that require little to no extra G-code editing for programmers.

Ultimately, outside of toolroom use, pretty much any production machine designed around a turning platform is being purchased with some sort of additional machining capability, live tooling at the very least. The days of moving work-in-process from lathes to mills to whatever other machines to complete parts are quickly becoming a thing of the past.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreAddressing Manufacturing Challenges with Automation

GrayMatter Robotics’ Physical AI robotic cells for manufacturing offer immediate impact and results.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More