New Direction: An Interview with Kurt Manufacturing

IMTS 2022: Brent Donaldson, executive editor of Modern Machine Shop, sits down with Paul Carlsen of Kurt Manufacturing, to chat about the company’s redesigned booth and how it’s designed to solve customer problems.

Kurt Manufacturing’s story started when it was founded in 1946 in Minneapolis. The company oversees four separate divisions of manufacturing — Kurt Machining, Kurt Die Casting, Kurt Workholding and Kurt Hydraulics. Within these four divisions, Kurt seeks to provide clients with high-quality products and solutions utilizing the company’s experience and expertise.

Brent Donaldson, executive editor of Modern Machine Shop, recently sat down with Paul Carlsen, vice president of corporate marketing at Kurt Manufacturing, to discuss Kurt’s booth at IMTS this year. In the meantime, MMS discovered more about Kurt’s complete branding overhaul and what the future looks like for the company.

Brent Donaldson, Modern Machine Shop: What should attendees know about what Kurt is doing at IMTS this year?

Paul Carlsen, Kurt Manufacturing: Certainly, we have a new display this year. We've got a whole new booth design, much more focused on automation products than in the past.

BD: Okay, let's dissect that a little bit. Can you talk about any new elements of the design itself?

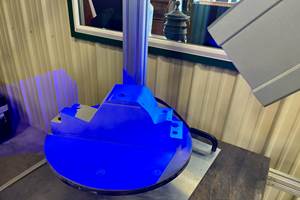

PC: In the past, we've normally had our standard products out on the show floor. Not a whole lot of moving parts, I guess, would be a good way to put it. This year, we've got two robots in the booth, one a larger Fanuc robot. It’s a 12-by-12-foot table, showing our products that work in an automation-type environment. So, think air vises and hydraulic vises. That larger robot is moving material in and out of hydraulic and air vises. There's a hydraulic pump system that'll be showcased alongside it, showing our other hydraulic solutions like our hydraulic hose and couplings. We also have a new robotic end effector gripper that is on both robots.

BD: What’s the other robot being featured?

PC: The other robot we have is a smaller cobot, and its primary focus is showing off that gripper. The RV 36 gripper has some unique feature sets to it.

The Kurt Workholding RV36 Gripper, being shown in action by both robots featured at Kurt’s booth at IMTS 2022.

Photo Credit: Kurt Manufacturing

BD: So, this year, it’s all about automation?

PC: No, actually. Along the back wall of the booth, we have all of our high-volume standard products. We've got our new five axis workholding line as well—that’ll be another big focus. It'll be six new main skews for that product line along with a bunch of accessories that work with them.

BD: What was the impetus for this booth redesign?

PC: Kurt has a pretty diverse set of divisions, including Workholding, Hydraulics and then Kurt Machining. We also have our Die Casting division. So, yeah, diverse, but all centered around the machining world. We went through a complete corporate branding overhaul between two and three years ago, and this is our first real opportunity to show off our new branding and marketing direction. A lot of the divisions were running a bit independently, so we consolidated all of that under the corporate umbrella. We’re putting a lot toward the booth because this is really our first opportunity to show this off. It’s a big change from what we’ve done in the past.

BD: With everything that you've talked about right now, is there any sort of background information about why you're highlighting these products?

PC: Like everyone, we've seen the investments in automation as the industry continues to change, and people are harder to find. So, we're doing everything we can to help machine shops with their labor and their labor problems, and get products out there that fill those needs.

Related Content

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreSimple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)