Oil Mist Collection Improves Employee Health, Safety

Using Fox oil mist collectors from LNS America, Staub Machine was able to improve air quality and reduce downtime needed to complete maintenance tasks.

Share

Just as we now know that smoking is bad for you, it follows that inhaling the particles produced in the machining process is not healthy either, says Tony Staub, president Staub Machine Company. To protect his employees’ health, Mr. Staub needed to filter the coolant vapors produced by machine tools in his Hamburg, New York machine shop. By using Fox oil mist collectors from LNS America (Cincinnati, Ohio), Staub Machine maintains a safer work environment that is free of oil residue.

Like many manufacturing companies, Staub began machining parts in a garage for various local manufacturers. During the past 38 years, the company has grown to supply machined components made of aluminum, brass, stainless steel and exotic alloys for medical equipment, industrial lighting, relief valves and more. The 34-employee company runs 20-plus machines, including 14 high speed lathes (four robot-assisted) and horizontal machining centers served by three pallet pools. Although Staub produces about 150,000 machined parts each week, the facility is neat and clean. The walls and ceilings are painted, the floor is epoxied, utility lines are color-coded and equipment is organized for optimum workflow. This clean journey began more than 15 years ago when the company began using various types of air filtration systems to keep the equipment and floors clean and provide a safe workplace. “We consider ourselves an environmentally conscious company, but beyond that, we spend a lot of time in the shop,” Mr. Staub says.

To begin cleaning the air, the company first purchased a spinning filter unit. However, Mr. Staub says this system produces an annoying, droning noise that is hard to listen to all day. While other technologies can remedy the noise problem, they too have serious drawbacks, such as repeated bearing and shaft failures and the need for frequent filter changes, he says. The company next tried electrostatic, collection-cell and ionizer-wire-based units, but they are not able to maintain consistent, high-quality air without constant cleaning and maintenance, Mr. Staub explains. For the electrostatic units, maintenance involves removing the cells and filters, cleaning them and replacing any broken wires. Ionizer wires alone cost about $1,500 per year for ionizer wires alone, he says.

In search of a better filtration method, the shop agreed to test a Fox oil mist collector from LNS. During the testing period, Mr. Staub says he didn’t want to rely solely on sight, smell and touch to determine how effectively the WS 700 model unit filters coolant residue. Instead, he wanted to see the hard data. To prove the collector’s efficiency, LNS brought in an air quality meter that uses laser technology to count the particles of contaminants in the air when it delivered the Fox oil mist collector.

Staub Machine set its own shop air quality standard at 0.5 mg/m3, which is more stringent than the the OSHA standard of 5.0 mg/m3. “When we first installed the LNS Fox test unit and began measuring its efficiency, we found that it consistently outperforms the other types of oil mist collectors in terms of controlling air quality and requires far less maintenance than the other systems in our shop,” Mr. Staub says. For example, the average air reading around the company’s other mist collectors is 2.0 mg/m3 before maintenance and 0.37mg/m3 after maintenance. The average reading (done at the same time) at the LNS Fox mist collector is 0.2 mg/ m3.

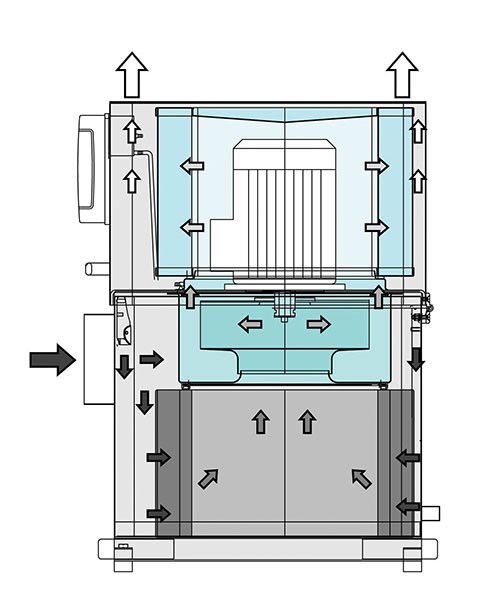

Charles Taylor, filtration product specialist at LNS, says the WS series of Fox oil mist collectors is ideal for controlling the heavy mist created by higher spindle speeds and high-pressure coolant delivery systems. Both are common at Staub, where lathes run at 6,000 rpm or higher and use 1,000-psi coolant delivery systems. To combat the mist, the filter works in three stages. During initial pre-filtration, special media consisting of three filtration layers removes and handles solid particles and bulk liquid entrainment with a slow draining effect. It also agglomerates finer mist droplets into larger ones. The second stage provides intermediate filtration, in which a special impeller enables continuous discharge of agglomerated mist particles/droplets from the first stage. The final filtration stage occurs in the extended filtration area, a multi-media arrangement that provides 99-percent efficiency per AFNOR NFX 44-060. Clogging is monitored by a pressure gage that indicates when the cartridge must be replaced.

Using the shop’s air particle counter, which Mr. Staub purchased after being impressed by the one from LNS, the company is better able to schedule maintenance on the different collectors used throughout the shop. Based on air quality tests before and after maintenance, the company developed a 3- to 4-week maintenance interval for the various other oil mist collectors used throughout the shop. These collectors take about 45 minutes to maintain, while the Fox unit takes about 30 minutes every 6 to 12 months. “Time spent cleaning and maintaining a mist collector is time that we could have spent making parts. It’s all about efficiency,” Mr. Staub says.

Within 6 months of evaluating the initial test unit, Staub Machine began purchasing additional mist collectors. The company now uses four Fox oil mist collectors—two 700s, a 330 and a 1520. Mr. Staub says the company will gradually replace the existing units over time by equipping any new machine the company acquires with the LNS units.

Related Content

Shop Tour Video: You've Never Seen a Manufacturing Facility Like This

Explore Marathon Precision’s multi-process approach to manufacturing, where blacksmiths and hand-forged dies meet state-of-the-art CNC machining. Discover how restoring classic muscle cars and building custom art projects creates a dynamic shop culture — and draws top talent to this unique and innovative metalworking facility.

Read MoreHow Proper Scheduling Leads to a Successful Machine Shop

Proper scheduling of jobs is paramount when it comes to running an efficient machine shop.

Read MorePreserve the Craft of Manufacturing as Technology Advances

As the industry continues to move toward a digital future, be sure to reinforce the core fundamentals right alongside it.

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read More.png;maxWidth=728;quality=90)

.png;maxWidth=300;quality=90)