Pick the Right Stock to Avoid a Bad Quote

Stock selection can have a big impact on a machine shop’s bottom line. When quoting a job, don’t fall into the trap of minimal material mentality.

Share

The past 50 years of manufacturing have been interesting, but the last year has been much more trying and challenging than most. Many companies have suffered due to the economics associated with the pandemic. However, in the machining sector, we are accustomed to constant challenges. These challenges include continuous changes in technology, automation, tooling, materials, software and other innovations that are introduced to the market each year. To protect our long-term viability, we must be aware of these changes and challenges but never lose sight of the decisions that affect our bottom line with every job.

One challenge that seems to come out of nowhere is a particularly irritating issue that I call “MMM.” Before I tell you what MMM stands for, here is how the issue arises. As a job shop, we quote and compete for many of the jobs that come our way. We look at the drawings and price out the materials, labor, post processes and any other special requests that are necessary to get the job done. Then, we send in our bids and hopefully we win the job. While this may seem straightforward, the issue of MMM sneaks into the process too often. Once it does, it can be hard to make the job profitable. .

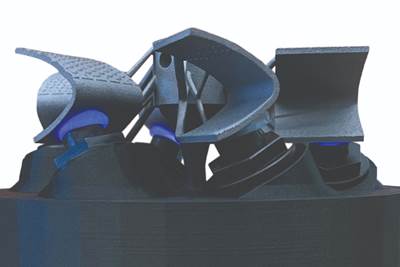

Now, allow me to explain MMM. It begins when our operations manager walks into my office with a huge, complicated fixture. It is obvious that a lot of time, money and effort has gone into the fixture. I often immediately realize that the cost of the fixture has eaten up much of the profitability of the job for which it is designed. This is where MMM has come to bite us and our profitability, again. By MMM, I mean “minimal material mentality.”

Our focus on keeping the cost of the material as low as possible makes the manufacturing process far more complicated and costly.

When we quote a job, we are trying to reduce material cost to win the job. We typically work out the quote using the smallest piece of material that will make the part. This is where we typically go wrong. We use this smallest piece of material because we were trained to quote this way, and it has led to success in the past. However, when we attempt to manufacture the part, we find that the small size of stock makes it necessary to build extraordinarily complex fixtures or create overly complicated processes to manufacture the part. Our focus on keeping the cost of the material as low as possible makes the manufacturing process far more complicated and costly.

It is frustrating to realize halfway through a job that our choice of stock is reducing our profit margin. I would like to blame it on many things, but in the end, I realize our quoting process is the cause. We focus far too much on keeping the input costs down and forget that it can escalate the manufacturing cost. We need to move very quickly in the jobbing world, and it is too easy to forget that MMM can cause many problems. Thankfully, it does not come up often, but when it does, it is a major disaster for profitability.

Even with my 50 years in the field, MMM still comes to bite me. The competitive nature of our business and its pressures makes it difficult to avoid. I am certain that many others have seen this from time to time as well.

The best advice for addressing this problem is to sit down and really think out quotes. It may be time-consuming now, but using the extra time in quoting is a great strategy to avoid MMM and unprofitable jobs.

So, remember MMM, take time quoting and be happier in the long run.

About the Author

Udo Jahn

Udo Jahn is the general manager of Modern Engineering, one of the larger five-axis machining providers on Canada’s west coast. Email udo@moderneng.com or visit moderneng.com.

Read Next

Q&A: Trends in Cutting Tool Application

Cutting tool technology is advancing and shops’ needs are changing as well. A leading cutting tool supplier offers this view.

Read MoreChoosing Workholding to Meet Machining Challenges

When it comes to workholding, shops can choose from options that can provide flexibility, help increase throughput and enable five-axis machining.

Read More2021 Will Be Dramatic, Too — How Is Your Tooling?

The time is now to take stock of your tools. Recently posted articles explore the potential impact of tooling technology.

Read More