Universal Robots (UR) recently released a new cobot called UR20 — a cobot with a lift capacity of 20kg, a 25% increase over anything the company has offered. As the use of cobots gains traction in job shops — specifically for machine tending, moving materials, and assisting with secondary operations — UR envisions the new model to work for a wider range of scenarios that previous models couldn’t handle. I spoke with Anders Beck, vice president of innovation at UR’s headquarters in Denmark, about the development of the UR20, technical hurdles the team had to overcome, and how the new model will impact the market.

Anders Beck, vice president of innovation at Universal Robots. Photo Credit: Universal Robots

MMS: What is the significance of offering a 20kg cobot and how will it impact your customers?

AB: We're very proud to launch a 20 kg cobot with 1,750mm of reach. To create a robot that delivers performance and reliability while fitting into human-scale tasks in the work environment has been important for us to get right. We had to redesign a lot of parts because our mechanical design has been around for quite a while, and the demands that this cobot put on the drive train we had been using created new challenges. We really wanted to make sure that we ironed out all of the functionality and make a mechanically superior product compared to where we came from.

In upgrading the drive train, we wanted to bring both a boost in uptime and reliability but also give a product that is really capable of sustaining a heavy load.

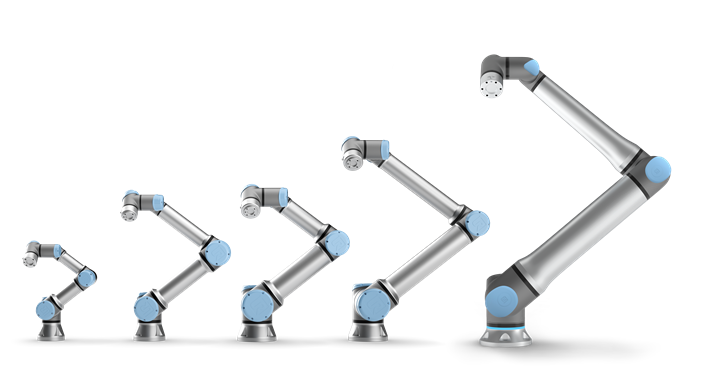

The UR20 has twice the reach and 25% more payload capacity than the previous generation of cobots from Universal Robots.

Photo Credit: Universal Robots

MMS: What was the need that Universal Robots identified here? What were the projected applications that drove the project?

Palletizing is a common way to demonstrate the abilities of a cobot. In machine shops, cobots fill many roles, from machine tending to part picking to quality inspection. Photo Credit: Universal Robots

AB: I think there's a lot of tasks out there that need this kind of work. Of course, there's packaging, palletizing and other situations where people carry boxes and stack them up high. It is common to see people in this industry moving 10 tons of material a day. Over a lifetime, that's not what we want for our workers. A lightweight robot capable of carrying that kind of weight will change people’s lives.

Having that work done by cobots enables people to stop doing that kind of work, but we’ll also see this cobot in other places like welding and machine tending. These cobots will support machine tools like lathes and CNCs because of the ability to reach further into machines and situations where heavy parts are now within its capacity. And because the whole installation has become a thing that is possible for most professionals, you don't need a lot of different stakeholders to be involved with the programming.

MMS: What kind of engineering upgrades made the UR20 possible?

We had to re-imagine the whole drive train. If you look at the base joint of the UR20, it produces a bit more than 700 Newton meters of force, so the torque it produces is huge but the repeatability at the end of the arm is still 50 microns. We had to work closely with our key vendors and we really thought through the whole mechanical design and simplified the process. We put our attention toward critical aspects of the cobot, especially with the rigidity of the system.

See the UR20 in action in this video by Universal Robots:

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreView From My Shop Video 1: A Deep Dive Into Automation with Advance CNC

Advance CNC leverages multiple forms of automation to increase its milling machines' productivity. Learn more in this episode of The View From My Shop.

Read MoreZero-Adjustment Bar Pullers Simplify Turning Automation

Spring-loaded grippers and adjustable programming are enabling bar pullers to fulfill their promise to save time and money in CNC turning automation.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)