Simplfying Thread Repair

Repairing damaged or worn threads on a workpiece is a common chore for toolroom lathes, especially in the oilfield industry. Haas Automation has a new feature for its conversational control units that simplifies and automates this process.

Share

Repairing damaged or worn threads on a workpiece is a common chore for toolroom lathes, especially in the oilfield industry. Haas Automation (Oxnard, California) has a new feature for its conversational control units that simplifies and automates this process. It’s now a standard feature on the company’s toolroom lathes and an option on its SL line of turning centers. The intent is to make thread repair simple and logical, thus making it consistent with the overall concept of the company’s Intuitive Programming System. This system allows machine operators to run jobs without using G-code programming and helps manual machinists make the transition to full CNC.

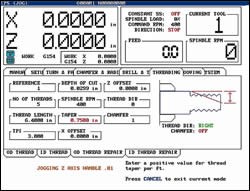

When one of the Repair Thread tabs on the general Threading page is selected, a screen opens as illustrated. After initializing the screen, the user jogs the axis feeds to position the tip of the threading insert at some point in the existing thread, using the graphic at the right as a guide. The user then enters the thread number corresponding to this position to update the graphic and to record the cutting tool coordinate position.

After that, the user fills in all of the entry boxes to supply values for different thread variables. Depth of cut and spindle RPM are preloaded with default values based on prior entries identifying the workpiece material, but these values can be overwritten with new entries to optimize machining. Software routines do all the required calculations to recut the thread from the insert’s starting point. The system automatically synchronizes the spindle to the thread pitch to chase the thread accurately.

Perhaps the handiest capability of this feature is coping with thread repair on tapers. This is done by entering a positive value for the thread taper in inches per foot. Workpieces with threaded tapers are quite common in oilfield work, so automating this part of the process is especially valuable in this application.

According to Frank Ramirez, the Haas product manager for CNC turning products who developed the software routines and the design of the thread repair page, this feature can reduce typical thread repair operations from 15 minutes of setup time to 1. “The operator can work from the control unit instead of eyeballing the insert in the cut while guessing what offsets to the right or left will center the insert in the thread,” he says.

The introduction of this thread repair feature coincides with the recent debut of the company’s TL-4 machine, a large-bore, long-bed toolroom lathe designed for the oilfield industry (see page 186). With oilfield work very active right now, the combination of this machine and the thread repair feature makes a timely appearance.

Related Content

-

Sandvik Coromant Solid End Mill Enhances Profiling Efficiency

Sandvik Coromant’s Coromill Plura Barrel end mill is designed for high process security and significant cycle time reductions in aerospace and other high-demand sectors.

-

Sandvik Coromant Turning Adapters Enhance Vibration Control

Sandvik Coromant’s Silent Tools turning adapters provide improved internal turning at long overhangs.

-

Greenleaf End Mills Optimize Machining Stability

Capstone-360 end mills are well suited for machining HRSAs, cast iron and hardened steel materials for the aerospace, oil and gas, power generation and medical industries.