Taking The Broad View On CAD/CAM Functionality

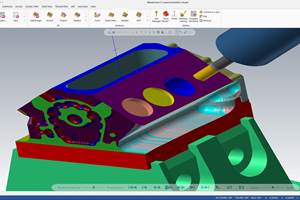

It is a complete CADD through CAM system that includes the SolidWorks solid modeler, multiple-surface milling, tool path simulation and verification, photorealistic rendering and animation

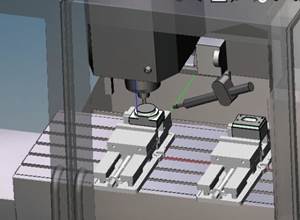

CAD/CAM technology has come a long way over the last decade. Affordable PC-based solid modelers, for instance, have grown very easy to use and now can handle surprisingly complex parts. Moreover, some CAM systems today are a snap to master with so much built-in machining process knowledge that very sound tool paths can be created with a small fraction of the clicks and keystrokes required only a few years ago. And these programs can be fully "tried out" in the virtual environment of an NC verification program.

What users can't necessarily get at a moderate price, however, is all these capabilities bundled into a single, integrated system. That's precisely what Manufacturing and Consulting Services, Inc. (Scottsdale, AZ) is after with the introduction of their new Anvil Express product line. It is, says the developer, a complete CADD through CAM system that includes the SolidWorks solid modeler, multiple-surface milling, tool path simulation and verification, photorealistic rendering and animation.

But rather than just bundling a lot of modules into a single wrapper, the developer has given a great deal of thought to how to make all this functionality work together, and how to make it easy to master. For instance, one of the most interesting features is how the system instructs first-time or occasional users on various aspects of the system's functionality. That includes a structured set of online, multimedia tutorials with separate exercises for novice, intermediate and experienced users. Because the tutorials include audio explanations, the user can listen to the instructions while paying complete attention to the interface, rather than having to constantly look back and forth from some form of instruction text to the screen.

The CAD functionality includes a number of tools for the creation of geometry. Besides solids, users can work with surfaces and wireframes. Models can be created parametrically so that workpiece features can be defined in terms of their relationship to other elements rather than specific dimensions. This way a through-hole, for instance, continues to be a through-hole regardless of the material thickness, even after modifications to the geometry.

The modeler also includes a new feature: "Autosnap 3-D." With this capability, once 2D geometry is created in two perpendicular planes, the system can automatically create a solid model from that data.

The combination of the solid modeler with a substantial amount of stored manufacturing knowledge allows the system to efficiently generate tool paths and deliver a surprising degree of NC programming automation. For example, once a tool is chosen for a given machining operation, the system automatically generates formula-based feeds and speeds as well as tool entries and retracts, based on the workpiece material and user-specified preferred practice. Moreover, modal files allow the user to store standardized manufacturing processes which quickly can be parametrically applied to the specific geometry of any appropriate workpiece or workpiece feature.

The initial release of the system runs on Pentium-based PCs running Windows NT 4.0, and the company is looking into porting it to Digital Alpha/NT workstations as well as Windows 95 and 97 platforms in the future.

According to the developer, the target market for the new CAD/CAM system includes "companies that use the disciplines of mechanical engineering to design and manufacture discrete parts and assemblies. The price of Anvil Express and its ease of use makes it suitable for small shops as well as major multinational corporations." If they are right about that, this well could be the model for a new generation of CAD/CAM systems that deliver an unprecedented combination of low cost and high functionality.

Related Content

Grinding Simulation Enables Growth in Custom Tooling

Simulation software both streamlines Gorilla Mill's grinding machine setups and speeds up the company's tooling design and verification processes.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreTTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreCAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)