Turning The Tough Stuff

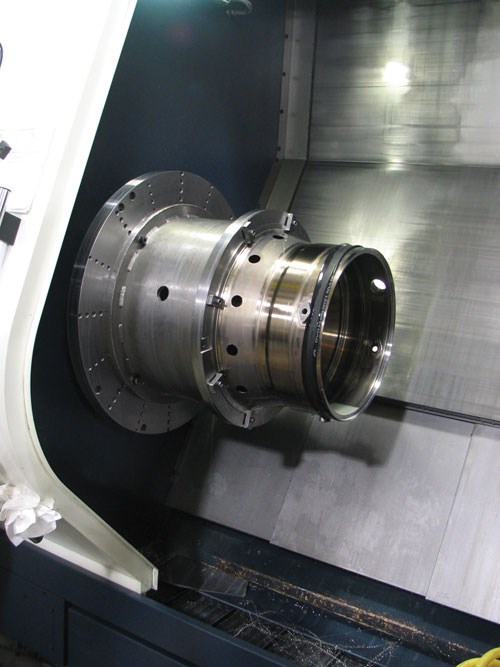

One of this aerospace shop’s many specialties is producing ring-shaped parts that are thin-walled, complex, tightly toleranced and made of difficult-to-machine materials such as Inconel, titanium or high-temperature alloys. Turning jet engine parts doesn’t get much tougher than this.

Gentz Industries, in Warren, Michigan, is one of those shops that some suppliers love to have as a customer while others do not. Having Gentz as a good customer will make a supplier better—and all of its other customers will benefit, as well.

Gentz might be called “challenging.” However, meeting challenges is the best way to get stronger. It’s not that the company is “difficult” or “demanding” or “always driving a hard bargain.” On the contrary, it is remarkably open, cooperative and fair. The issue is that Gentz is dedicated to some uniquely challenging production requirements in aerospace and power generation. Fabricating complex turbine engine components for the commercial and military marketplace is a major part of its business. These components include combustion cases, high-pressure turbine housings and exhaust casings. In addition to CNC machining processes such as turning, milling and electrical discharge machining, the shop has extensive expertise in forming sheet metal using hydraulic presses, laser cutting, waterjet cutting, hydro-forming and other processes. Perhaps its most outstanding capability is assembling numerous machined and formed pieces into finished products using TIG welding, electron beam welding, vacuum furnace brazing and other advanced joining techniques.

Needless to say, quality requirements for jet engine components are extremely stringent, and meeting these requirements is Gentz’s top priority—the shop’s reputation in the industry hinges on it. Other top concerns are efficiency and cost control, which determine the shop’s profitability.

It is noteworthy that in the past couple of years, Gentz has changed its approach to buying cutting tools. In the same period, it has also changed its philosophy about investing in machine tools. These changes are one reason why the company manages to continually cut machining time, reduce setups and minimize part handling while consistently hitting quality and cost targets. Interestingly, Gentz is spending more on specially developed inserts and customized toolholder styles, while it has moved away from buying expensive, high-end machine tools. In both cases, however, this reflects that the company has become more value-conscious.

Being value-conscious when it comes to cutting tool spending as well as to investing in machine tools makes a big difference. This company buys a lot of cutting tools. According to Mark McWilliams, purchasing manager, the shop spends about $1.25 million a year on carbide inserts. Gentz has also been buying quite a few machine tools, especially in the last year or so as it ramped up for production of the turbine case for the Pratt & Whitney 150 jet engine. Since the beginning of 2007, the company has installed 10 new CNC machine tools.

To get the most out of its spending on carbide inserts and related cutting tool products, Gentz has developed a very unusual approach to working with its main cutting tool supplier, Seco Tools (Troy, Michigan), and Seco’s local distributor, E & R Industrial. The shop conducts monthly forums in which it presents its most pressing machining challenges to these suppliers. These forums have had notable success in turning applications, although milling has also benefited.

Although the new philosophy that Gentz is following in machine tool investments may not be as groundbreaking, it deserves equal attention. Up until the last 2 or 3 years, the shop had a “you get what you pay for” mentality that prevailed in new machine purchases. This led the shop to acquire mostly expensive machines, many of them from Japan. Although these machines are still highly regarded as very productive assets, the company has taken a different direction. For its most difficult turning applications in Inconel and other exotic alloys, Gentz has acquired a number of Taiwanese machines such as horizontal lathes and VMCs from Johnford and vertical lathes from You Ji. This change in thinking is largely due to the efforts of Absolute Machine Tools (Lorain, Ohio), the U.S. importer, and its distributor, Single Source Technologies. These machines both meet Gentz’s demanding performance criteria and represent “more machines for the money.” According to Roger Bartolemei, Gentz COO, turning to Taiwan-built machines allowed the shop to acquire both the capability and the capacity it needs to keep up with growing demand for its jet engine components.

AN OEM AND REPAIR JOB SHOP

Although Gentz’s approach to certain supplier relationships may be atypical, the shop stands out in other ways. It produces long runs of complex parts in low volumes. OEM products account for about 80 to 85 percent of its sales. Fifteen to 20 percent of sales is “overhaul” work—repairing, refurbishing and upgrading critical jet engine parts. Because an overhaul job often must be turned around immediately to get an aircraft back into the air, Gentz follows principles of “quick response manufacturing,” a variation of lean manufacturing techniques suitable for job shop environments. Machine tools are arranged in cells that are self-sufficient in completing a set of operations. Quick changeover, standardized tooling and visual manufacturing (keeping everything in sight and clearly marked for foolproof identification) are practiced throughout the shop areas.The company has been evolving along these lines for years but has remained true to its roots as an aerospace shop job since its founding in 1949. The company’s current location in Warren is a short distance from its original site. Its most recent expansion, completed in December 2007, brought its total manufacturing space to about 132,000 square feet. Gentz has a growing workforce, too, which is nearing 300.

The company’s approach to manufacturing is truly comprehensive. Its engineers work with customers’ designers to improve not only the manufacturability of components but also their repairability. Gentz can develop repair and maintenance manuals as it is developing OEM production processes and provide repair packages with the delivery of the completed components. Production processes, however, do not remain fixed after start up. Thinking about ways to streamline operations and reduce costs begins right away.

A seeming paradox is that the company is at once both cautious and aggressive about attempts to improve its manufacturing processes. A component can represent tens of thousands of dollars in added value by the time it reaches a certain operation. If that operation is stable and predictable, the shop is understandably wary of changes that might disrupt the status quo. When the status quo represents a bottleneck, excessive cutter consumption, resistance to automation or other less-than-ideal performance levels from the machine, the shop actively seeks a better way.

This is one reason why interactions with machine tool suppliers and cutting tool manufacturers make a big difference for Gentz.

TOOLING FORUMS

The monthly “tooling forums” are a good example of how Gentz takes interactions with a supplier to a new and beneficial level. Attendees include Gentz personnel who represent the CNC programming, engineering and purchasing departments. Mr. Bartolomei and Jim Stevens, OEM manufacturing manager, are usually part of the Gentz team at these meetings, indicating the level of top management support for this process.Belinda Smith, an application engineer for Seco, usually joins her counterpart from E & R Industrial at these meetings. When the idea for these forums first emerged a couple of years ago, the invitation to participate was extended to other cutting tool manufacturers whose products were in use at Gentz, but Seco was the only one to embrace the concept enthusiastically.

Meetings usually focus on a particular operation that needs attention. In essence, these forums give Gentz a chance to challenge the tooling supplier to find a better way to perform that operation. After identifying areas of concern or dissatisfaction, the group discusses options and alternatives before deciding on specific improvement projects to pursue. These projects are prioritized and added to the “action register,” a list of on-going projects that includes a start date, an anticipated completion date and notes about specific performance targets to meet. The action register is the chief outcome of each of the forums, which usually last about 90 minutes.

Often, Seco has developed new cutting grades, insert geometries or insert coatings in response to action register items. When these “Gentz specials” prove themselves on the shop floor, some are likely to become a standard item in the Seco catalog. Others are unique solutions to the unique difficulties imposed by the advanced designs of Gentz’s workpieces.

The Gentz team understands that cost concerns must focus on the cost of the cut, not the cost of the cutter. A specially designed tool is likely to cost more, sometimes considerably more, than a standard item. Part cost analysis helps make the value of a more costly insert or cutter assembly apparent and justifiable. Likewise, the team recognizes that it has to be open to concepts that challenge its notion of tooling practices. This may mean running a tool at speeds or feeds that cause some nervousness during trial cuts.

An early example of successful cooperation between Gentz and Seco involved a thread milling operation in an Inconel combustion casing. Based on input from the tooling supplier, the shop was able to save more than $60,000 a year by reducing the time to complete 52 threaded holes in each casing and eliminate hand tapping to finish each hole. When initially developing the production process for this part, the shop wanted to use a 0.156 inch thread mill. Unfortunately, mills of this size from other suppliers could not cut the threads to full size without breaking. As a result, the shop had to settle for using a larger thread mill that that was not as weak, taking three light passes in each hole and leaving the threads undersized. Manually tapping each hole to full size required an additional ninety minutes on average per casing.

Ms. Smith believed that the shop could still produce the holes to size with a 0.156 inch thread mill from Seco’s Threadmaster series. These solid carbide tools are designed with a micrograin carbide structure and a TiCN coating. However, other changes also had to be made. To optimize cutting conditions for this grade, feedrates would have to be doubled to 194 ipm and spindle speeds upped to 5,000 rpm (the most the machine could deliver). Switching to a heat-shrink toolholding system would also be necessary to minimize runout at these settings, she insisted. Even programming routines would have to be modified. Although the proposed changes seemed extreme at first, the logic of the systems approach was compelling. In tests, the new thread mill proved to have the strength and wear resistance to produce full-size threads in two passes instead of three.

Several lessons emerged from this experience. For one, it was essential to involve engineering, programming and the shop floor staff in the discussion. For another, it was important to consider not only the cutting tool, but also the toolholder, machining parameters and programming routines. Moreover, it was necessary to have a representative of the cutting tool manufacturer present for the machining trials to make sure that all recommendations were carried out fully and that test cuts were performed fairly.

RETHINKING VALUE

Although it’s never too late to improve an operation by developing a new tooling solution, it’s much tougher to overcome constraints or inefficiencies stemming from the limitations of a machine tool. Because Gentz thoroughly understands its workpieces, from design intent through maintenance and repair cycles, the company uses this insight to set forth requirements for new machines in no uncertain terms. Yet being flexible and pragmatic has served the shop well. The recent shift to “value-priced” machines from Taiwan, for example, is consistent with the company’s characteristic openness to change.Lately, the shop has concentrated on boosting production of thin-walled housings and casings in high-temperature alloys such as Inconel 718, a material it encounters frequently. Demand for these parts has surged, especially now that Gentz has new contracts for the Pratt & Whitney 150 engine turbine housings. Typically, both the OD and the ID of these parts are characterized by complex contours and grooves with fine surface finish requirements. Some housings approach 40 inches in diameter and stand as tall as 30 inches. Most start out as forgings that may weigh as much as 3 or 4 times more than the finished part. After machining, walls may be as thin as 0.06 or 0.08 inch. Dimensional tolerance on diameters is typically 0.001 inch. The tolerances on the widths of intricate slots and grooves are often just as tight.

To meet the surging orders, Mr. Bartolomei initially wanted to stick with the customary turning centers. However, distributor Single Source Technologies directed him toward a Johnford ST model slantbed turning center that had the unusually large swing needed to handle the full range of casing diameters. Despite this, Mr. Bartolomei was hesitant. Shouldn’t we be considering the more expensive machines we’re used to, he wondered. In his mind, the rigidity, reliability and accuracy of these machines could be taken for granted.

Keith Kauzlarich, vice president sales at SST, knew that Gentz was uncompromising in its expectations for top quality machines backed by a high level of service and support. However, he could see that the Johnfords and other machines from Taiwan would be a good fit. For example,

the Johnford turning center had not only the exceptional swing that the shop was looking for, but also other characteristics that make it especially suitable for machining Inconel.

Chief of these is rigidity. The weight and size of its bed casting as well as the boxway construction on the axes would absorb vibrations from the forces involved in machining Inconel. (As a workpiece material, Inconel is both tough to machine and highly sensitive to vibrations, so it is prone to chatter.) The 60-hp spindle motor and large spindle bearings on this lathe would provide the power for these cuts, especially in roughing when high torque at low rpm is needed. Also, the 60-degree angle of the slant of the bed lets an operator get close to the parts in the work zone.

Steve Ortner, president of Absolute Machine Tools, believes that machines from this builder now hold an advantage over comparable models from Japan because Johnford did not follow the trend to lighter, low-mass designs favored by Japanese builders for high-speed machining applications. For example, he points out that the heavier Meehanite castings on these lathes provide the exceptional rigidity needed for cutting the tough aerospace alloys faced by Gentz.

In addition to conventional turning centers, Gentz also needed to expand its resources for vertical turning. However, the long lead times on its preferred choices ruled them out. Mr. Bartolomei was directed to VTL models from You Ji, another line from Taiwan imported by Absolute Machine Tools. As Mr. Ortner points out, these machines not only met the specifications, but were also very reliable products with proven track records in aerospace work. Moreover, the model sizes that Gentz was looking for were available from the factory with short delivery times.

One point that added to skepticism about the Taiwanese machines was price. Both brands were significantly less expensive than what Gentz was expecting to invest. This was a company that never went bargain hunting when it came to machine tool purchases. Skimping on manufacturing equipment was not its style and not the way to ensure quality work in the very demanding aerospace industry.

Ultimately, SST arranged to have the Gentz team meet at Absolute’s headquarters in Ohio for demonstrations of the Johnford and You Ji machines. Visits to customers in the area who had installed these brands in aerospace applications very similar to those at Gentz were also arranged. Both users were machining Inconel with great success. This was enough to convince the shop to go ahead with an order. The first two Johnford lathes were installed facing each other in a cell with an overhead crane in the middle to aid load and unloading. A similar cell with two You Ji VTLs was installed not long after.

According to Mr. Bartolomei, the machines performed so well that repeat orders for machines from both builders have followed. This includes a pair of Johnford SV-41H VMCs with four-axis rotary tables. Like almost all of the machines at Gentz, the new slantbeds, VTLs and VMCs are on duty 24 hours a day, 6 days a week. The reliability record for these machines has exceeded expectations, although it should be noted that Gentz has a disciplined preventive maintenance program in place as part of its lean manufacturing and continuous improvement efforts.

MANUFACTURING’S FUTURE

Gentz’s success in aerospace is seen as a model for the survival of manufacturing in southeastern Michigan. Many observers have witnessed the decline of the automotive factories in the area and the job losses that go along, only to conclude that manufacturing has no future in this region. Gentz clearly contradicts this outlook.In addition to creating good paying jobs for a growing workforce within its own facilities, Gentz supports other manufacturing companies in the area when it needs one of the processes it does not currently provide in-house. It also supports local supplier companies such as Seco Tools and Single Source Technologies. However, everyone at Gentz understands that continued success is never guaranteed. The company has to renew is strength by challenging itself, by challenging its suppliers, and by keeping its customers strong as well.

Related Content

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Read MoreHow to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read More10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreWatchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreRead Next

Striving To Be Partners, Not Shops

The two divisions within this business machine complex parts for the medical and aerospace industries. So in that sense they’re shops. However, in order to grow with their customers, they realized they had to be more than just providers of good parts. They needed to serve as their customers’ manufacturing partners.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More