Traditional quoting processes are typically based on experience and estimates. The danger with this approach is that an inaccurate quote may have negative consequences: A quote on the high side will not be competitive and the job will be lost, or a quote on the low side will win the job but the shop will lose money fulfilling it (and a quote on the slow side won’t be considered at all). Pierre Slabber, president and owner of SecturaSoft, a software firm dedicated to solutions for manufacturers, fabricators, machining job shops and steel service centers, says this traditional quoting process must be replaced by an automated system that does not rely on guesswork.

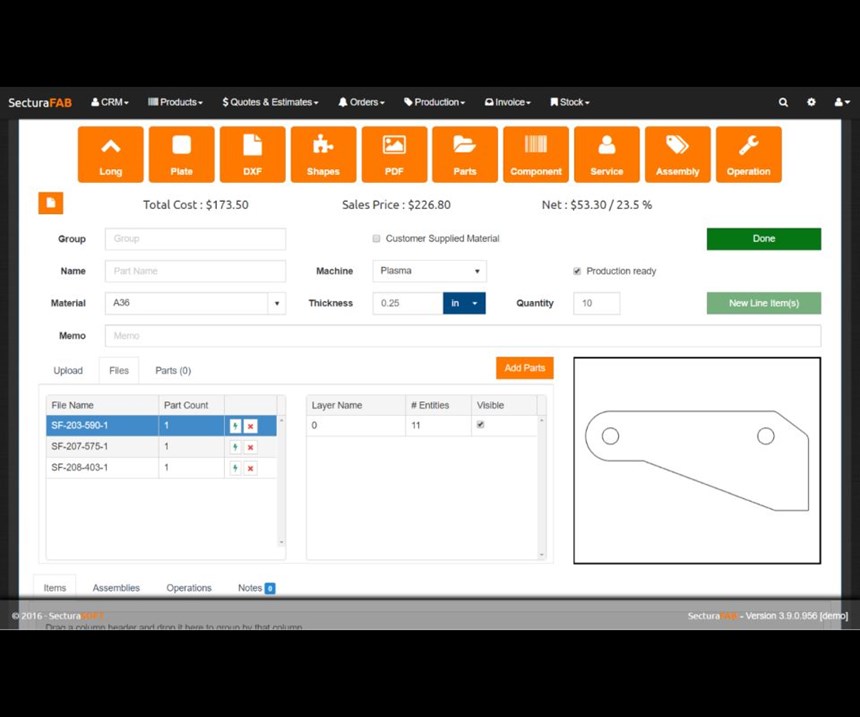

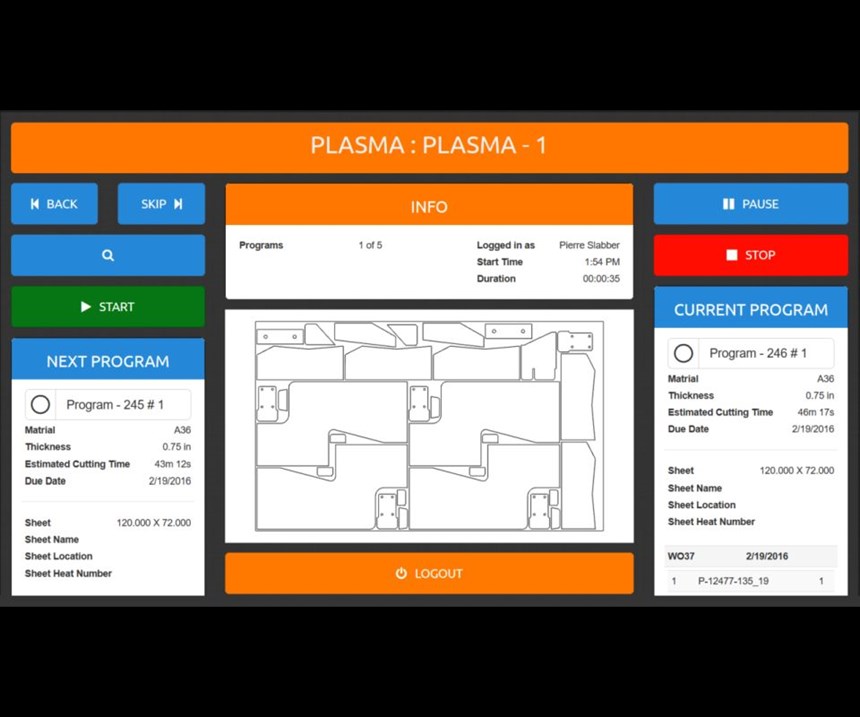

His company's main software offering, SecturaFab, is designed to eliminate guesswork and accelerate the quoting process by leveraging the capabilities of computers, databases and intelligent algorithms with the intelligence of today’s CAD models and data linkages. The software also provides a standardized, company-wide quoting format. He says this approach makes it easier and faster to generate accurate, competitive quotations and production instructions. Although SecturaFab is designed primarily for fabricators who cut, weld and form metal products from plate or sheet, the underlying concepts and methods are being adopted for machining job shops as well. According to Mr. Slabber, a number of machine shops are already using early versions of the software as an advanced quoting system. The rollout of the machine-shop version of this quoting system is expected in the second quarter of this year.

The current quoting system is based on these concepts as outlined by Mr. Slabber: It is web-based, so quotes can be prepared on virtually any internet-enabled devices, such as PCs, laptops, tablets or cellphones. Being web-based also enables the system to be powered by cloud-based processing using algorithms for complex but rapid calculations, and databases that are extensive and comprehensive. A software-as-a-service pricing model also makes this cloud-based approach less costly to the end user.

Standardized, common templates and user-populated data fields provide customized calculations based on the user's rates for services, material costs, machine run time, secondary operations needed and associated costs, plus other variables. Calculations performed in the cloud can be launched behind the scenes once user data is entered so the results are ready when the application is used to prepare a quote later.

Perhaps most important, the algorithms applied in the quoting process are designed to be "intelligent," that is, they are based on part geometry automatically extracted from a CAD file of the part. In SecturaFab, multiple nesting algorithms are built into the quoting platform, Mr. Slabber explains. The algorithms are also intelligent in their ability to apply machine technology tables – information about the performance and capability of the laser, plasma cutter, waterjet, flame cutter or other profile-cutting equipment. In addition, SecturaFab is an open system that enables these tables to be changed by users to suit their environment.

Part geometry is best derived from native CAD files or files in a neutral geometry format. However, Mr. Slabber says the system can draw from a library of generic "smart shapes" that represent detailed but generalized workpieces the user encounters most often. These smart shapes are created by entering dimensions in data fields, which use SecturaFab’s CAD system in the background to draw the DFX/DWG file. Once these dimensioned drawings are created, the user can nest them or obtain run times without opening CAD sotware.

The software is also designed for integration, so it can not only draw info from CAD files, but it can also check the shop's inventory database to determine if enough stock is available to complete the job. If additional material must be ordered, up-to-date material costs can be applied to the quote at that point. According to Mr. Slabber, quotes that are accepted by the customer will have already been analyzed for production and can be sent directly to an enterprise resource planning (ERP)/nesting system, along with workorders and route cards. As a benefit, the process of turning a quote into an order does not require re-entering data, a step that might delay production.

Mr. Slabber explains that this level of integration should not be surprising to most users. He says it is not unlike comparing the experience of travel planning not long ago with today's online technology: "Formerly, when planning a vacation, we might break out a map and plot a route to our destination. We would identify potential side trips, investigate places to stop along the way, perhaps add up all the miles to determine how much it was going to cost with current gas prices. All of the information for this was available; we just had to put in some time and effort to collect and calculate it. Today, the same task is performed with a push of a button."

Now, he says, Google instantly maps the journey and enables the trip planner to evaluate alternative routes. "We know travel time, and can see where detours, traffic delays or construction will be encountered. We can identify stations with the best gas prices. It may show points of interest and instantly connect us to those attractions. Theoretically, we can even upload the map and route to our car's GPS." He says his quoting system seeks to emulate an ease of use and completeness that is similar to the experience travelers have come to expect from this technology.

Finally, Mr. Slabber points out that the quoting process has to be accompanied by a firm focus on profitability. Winning or losing quoted jobs is not the real issue; filling the shop with consistently profitable jobs is what counts, he says. In fact, timely, accurate quoting can uncover "opportunity capacity" for which a shop can identify additional jobs that utilize machine capacity and available stock at a highly competitive rate without disrupting the shop's overall profitability at the end of the month.

He sums up this outlook: "Using known pricing, run time and other production variables applied to geometry-based intelligence, a shop can use web-based quoting to dictate profitability — not hope for it."

Related Content

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)