ZF Goes to Nine Speeds

To help global automakers achieve greater fuel efficiency, ZF Friedrichshafen AG is developing transmissions that are deploying an increasing number of gears.

German manufacturer ZF Friedrichshafen AG makes a lot of gears. For manual transmissions. For automatic transmissions. For dual-clutch transmissions. It makes axle drives, including bevel gear sets. It manufactures products the world over, including a facility it opened last year in Gray Court, S.C. In total, the company produces approximately 2.5 million transmissions per year.

The demand for ZF products (which include other products, such as driveline and chassis components) is growing significantly. According to Dr. Stefan Sommer, CEO of ZF, company sales in North America were $4.2 billion. Speaking to why the sales were so robust, Sommer says, “The primary reason for this is the demand for energy efficient automatic passenger car transmissions.”

ZF introduced eight-speed automatic passenger car transmissions in 2009. ZF produces this transmission for front-longitudinal applications in Gray Court; Chrysler produces it under license. The transmission is proving to be a big hit in vehicles ranging from the stylish Chrysler 300 sedan to the durable Ram 1500 light-duty pickup.

An interesting aspect of ZF’s approach is that it keeps trumping itself. It introduced a six-speed automatic transmission in 2006, and then a brief three years later, there was the eight. The driver: It provides a 6-percent improvement in fuel efficiency compared with its own six-speed. (Note that ZF engineers are confident enough to make comparisons with a product that they themselves developed. This is an indicator of proficient product development at work.)

And now, the company, along with Chrysler, is producing a nine-speed automatic for front-traverse applications. Dr. Sommer says that in order to accommodate the production of the eight- and nine-speeds, Gray Court, which was opened in July 2013, is being expanded from its current 968,752 square feet to 1.4 million by 2016. Employment will go from 1,200 to 1,650 people.

Here’s the thing about the nine-speed. While six-speed automatics are still comparatively contemporary in front-wheel-drive applications, the nine provides significant fuel economy improvements. At a constant speed of 74.56 mph, the nine-speed can reduce fuel consumption by as much as 16 percent compared with the six-speed.

One of the challenges that ZF took on in developing this new transmission is that of space. While it is comparatively easier to accommodate more gears in a longitudinal configuration, in a traverse design, there is less room to package the transmission, especially when you’ve upped the number from six to nine. Also realize that most cars that deploy transversely oriented transmissions are small to midsize, so there is a set space constraint. Given that about 75 percent of all cars have a traverse setup, this is a great opportunity for ZF.

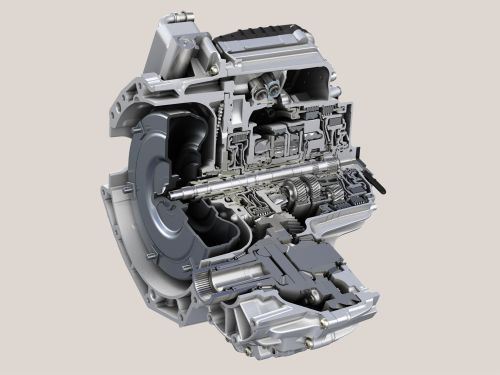

So the company capitalized on the opportunity while paying keen attention to constraints. Realize also that in the segment of the market in which the transmission was developed to be deployed, there is considerable price sensitivity, so it had to engineer the product with that in mind, too. It created the nine-speed with four simple gear sets, six shift elements, and two dog clutches, each with two multidisc clutches and two multidisc brakes. The total spread is 9.81.

The setup features two planetary gear sets on top of each other; consequently, there are never more than three gear sets in a row.

There are two series in the nine-speed range, and the torque spread is from 200 to 480 kNm.

Another way that ZF saved space was to install the electronic control unit (ECU) on the upper side of the transmission housing rather than with the reduced-size hydraulic control unit. The sensors within the transmission providing vehicle-side signals are connected to the ECU via its male plug. ZF engineers found that it was necessary to develop and produce the ECU for the nine-speed, the first time the company has done it.

While there is likely to be an increase in the number of gears going forward, a more likely scenario is the use of hybrid technology to improve overall fuel efficiency. ZF has cleverly protected the nine-speed’s future integrity for integration with hybrid components. What’s more, the transmission also lends itself for use in all-wheel-drive setups.

Read Next

10 Things That Caught My Eye at Gear Expo

Check out a slideshow of equipment spotted at the 2013 edition of Gear Expo, the show’s largest edition in more than a decade.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)