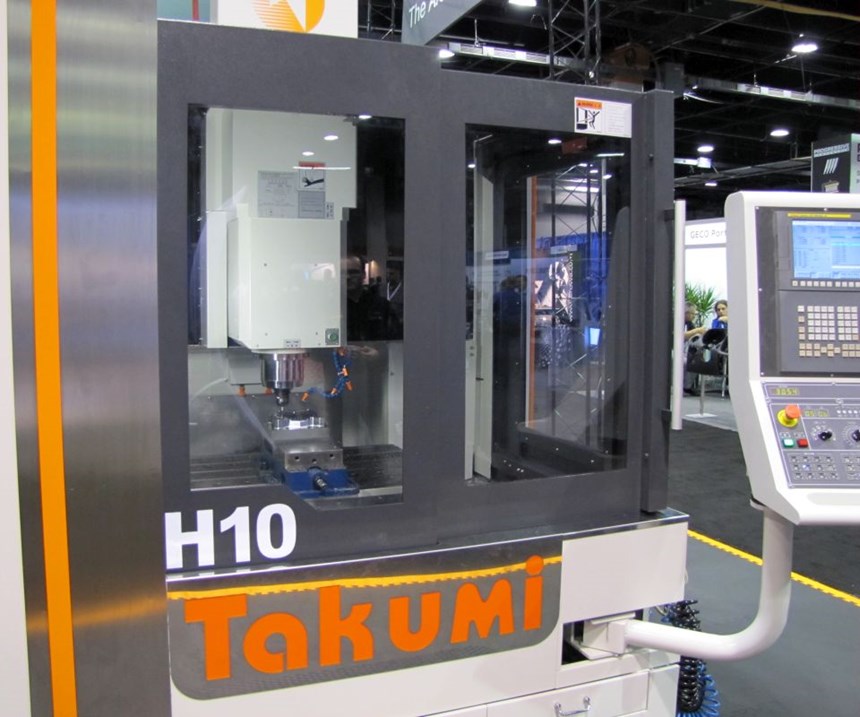

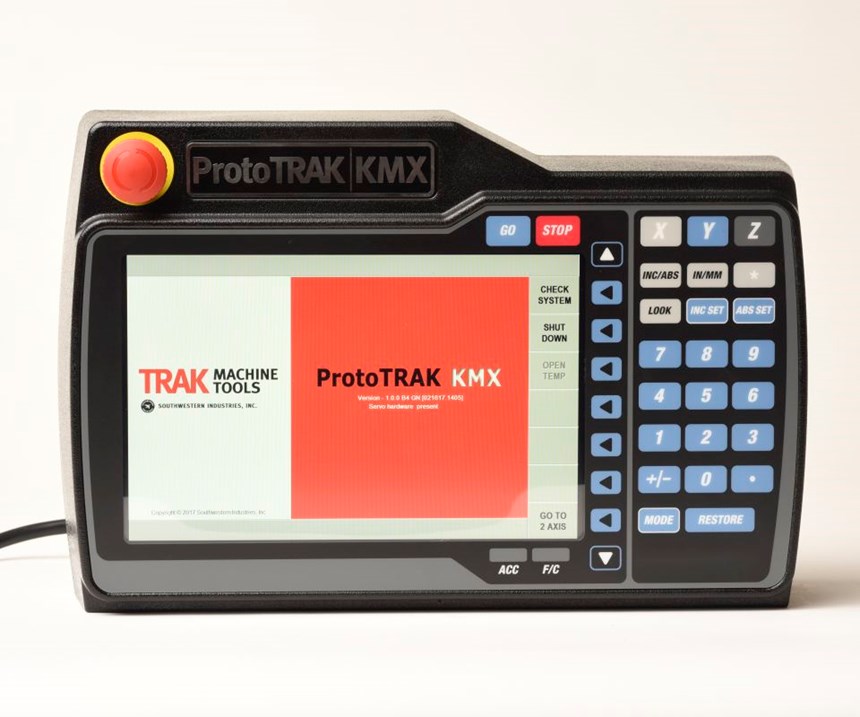

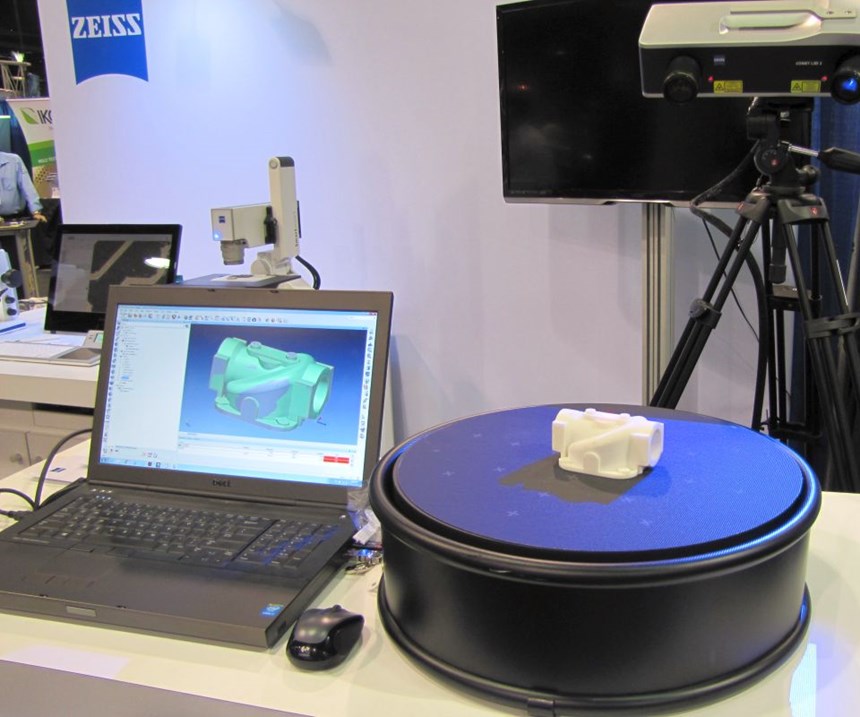

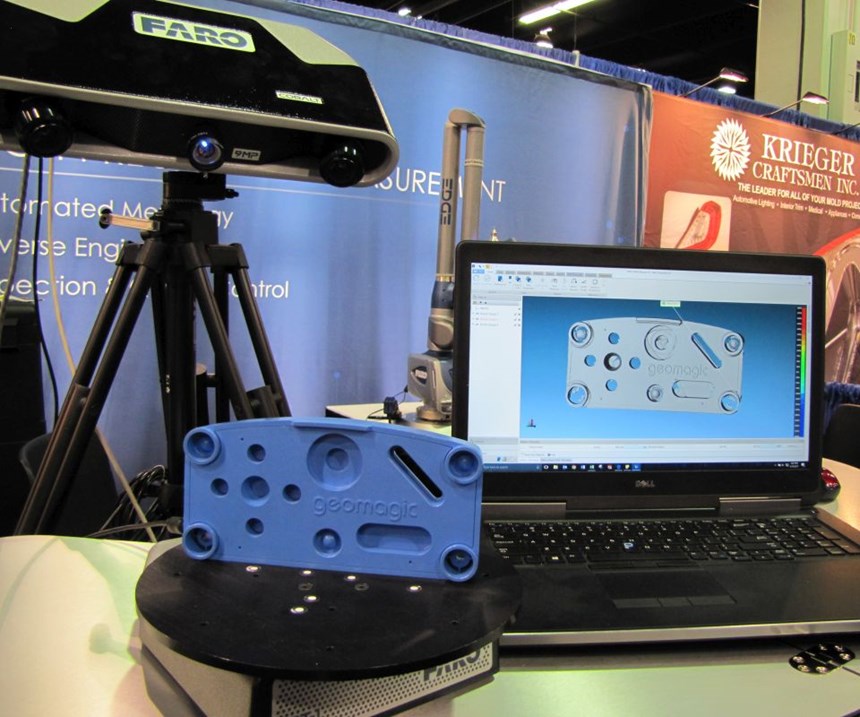

Amerimold: Moldmaking's Biggest Show Captures Current Metalworking Technology

Many of the emerging developments and key trends in metalworking technology were represented at this show, making it a revealing cross-section of current advances.

Although the Amerimold event is primarily targeted to manufacturing companies involved in plastic injection molds, anyone interested in the advanced technology that is critical to mold machining could find useful, valuable information there. In fact, I went looking for product news and application insights that would be of interest to the metalworking industry at large. There was plenty to see. Almost all of the emerging developments and key trends in metalworking technology were represented at this show, as the highlights of my discoveries illustrate.

Related Content

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

-

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

.png;maxWidth=970;quality=90)