Investing in Tech Is a Strategy, Figuring ROI Is a Strategic Tool

This short article by Jeff Reinert, president of Index Corp., outlines the multi-step process for justifying an investment in the latest CNC machining technology. Calculating the return on investment (ROI) is a useful step in this process, but only one of the factors a manufacturer must consider in the decision to buy a new machine. Read the article here.

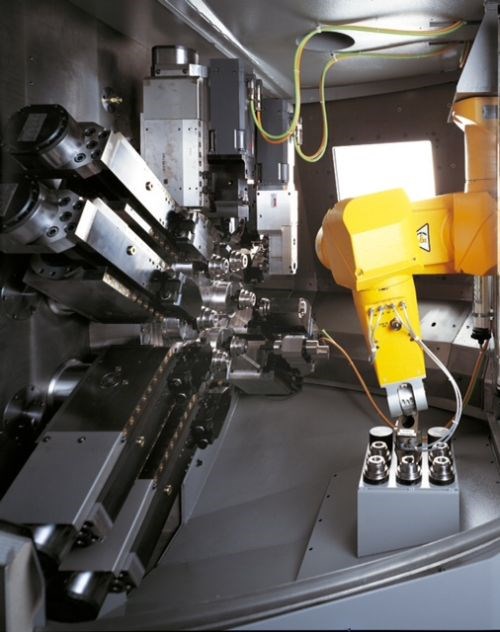

Why invest in new CNC technology that seems unfamiliar, even a little scary? Jeff Reinert says that a bold approach to justification can show shops that they need to jump in if they want to compete.

This short article by Jeff Reinert, president of Index Corp., outlines the multi-step process for justifying an investment in the latest CNC machining technology. Calculating the return on investment (ROI) is a useful tool, but only one of the factors a manufacturer must consider in the decision to buy a new machine.

Reinert identifies three main steps:

- Understand your machining costs and evaluate impact of a faster, more capable process.

- Understand potential benefits of the latest CNC technology (Reinert lists eight measurable ones as a start).

- Understand the costs of older equipment (including operator skills that may vanish).

After taking these steps, calculating ROI can be a concise and useful analysis to back up a decision. However, as Reinert explains, ROI is not the same as profitability and competitiveness. His advice puts the ROI calculation in perspective.

Related Content

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

-

Will the “Great Resignation” Become an Opportunity for Manufacturers? Get Ready for the Returning 3 Million

The Great Resignation will become a Great Reapplication when employees currently able to stay out of the workforce return to it looking for something better. Machining employers that are already evaluating candidates for fit, without demanding specific skills coming in, might be positioned well to draw upon this wave.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. Derek Korn, Production Machining’s editor in chief, shares suggestions from a CNC machine shop.