Job Shop’s Peg System Simplifies CMM Inspection

A work positioning device deals with job variety while still allowing less experienced employees to inspect parts on their own.

Share

In many machining facilities, setup and inspection are operations that only employees at a certain level perform. Newer or less skilled employees don’t carry out these steps.

Is it possible to simplify these steps so that the distinction isn’t necessary? Can employees with less experience be equipped to perform operations such as these?

In some cases, yes. Like many machine shops, Beistel Machining of Donora, Pennsylvania, tries to overcome the difficulty with finding experienced machining employees by hiring promising inexperienced candidates who can learn on the job. In addition, shop owner Brent Beistel tries to go even farther than this, engineering systems that allow for the job shop’s high variety of work while still enabling inexperienced employees to carry out critical steps effectively and on their own.

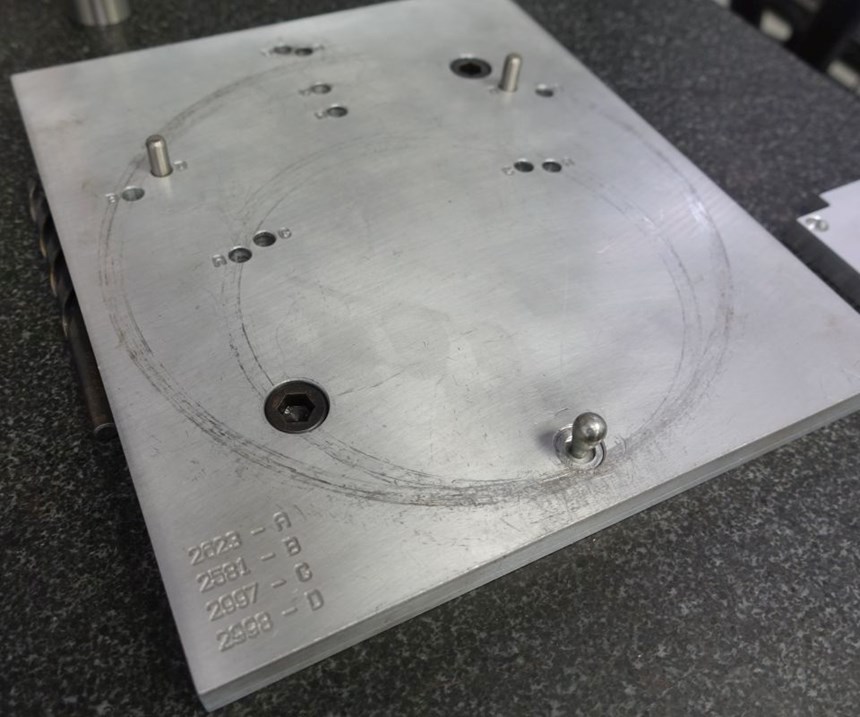

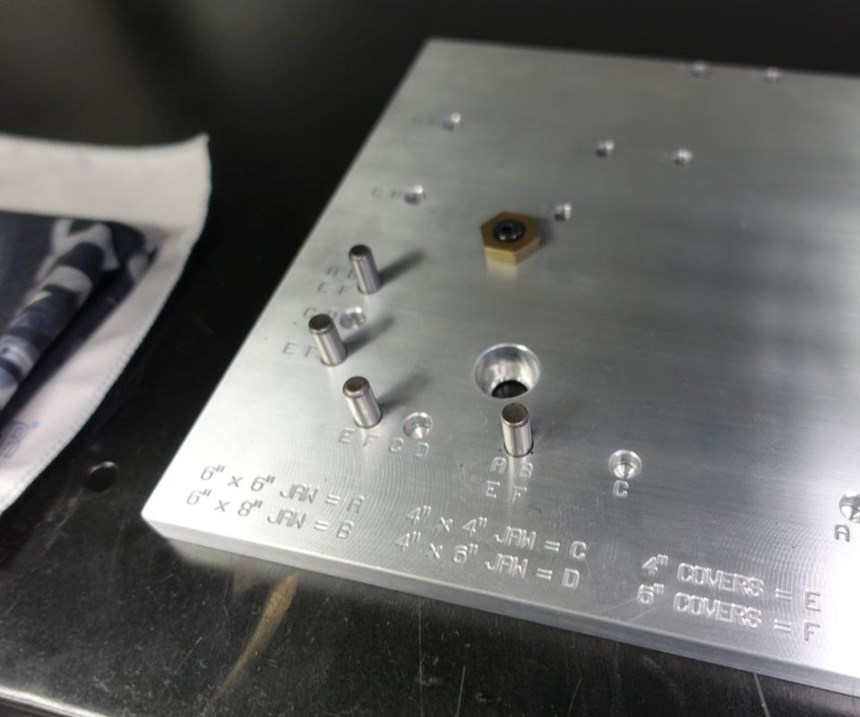

The photos above show an example. Mr. Beistel developed a work positioning device for CMM inspection that is quickly and easily adaptable to different part numbers. As the photos show, a single fixture includes holes for the locating stops for various part numbers. The user simply has to place pegs in all of the holes corresponding to the part in need of inspection—information engraved into the fixture itself. With these pegs in place, the part will be positioned correctly for the inspection routine for that particular part. Thus, the same work positioning device can remain in place on the CMM table as various different part numbers are being run, and an inexperienced operator can effectively “set up” the CMM for inspecting a new part. He or she simply inserts the pegs, positions the work using those pegs, and calls up the CMM program for that part.

For more on Beistel Machining and its inventions, read about one-handed quick change of soft jaws.

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

-

A Balancing Act for Differential Gaging

Differential gaging measures using two devices, which has advantages over standard, comparative measurements using a single sensing head. These include the ability to measure size without regard to position.