Looking at the Benefits of Cloud-Based CAM

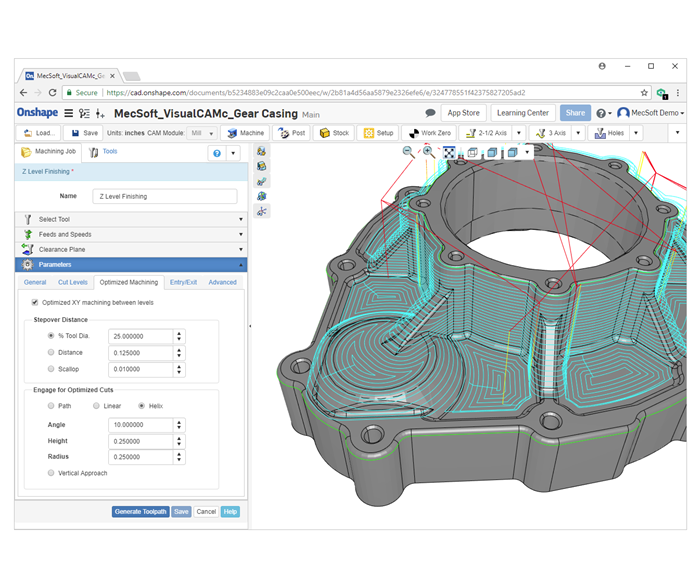

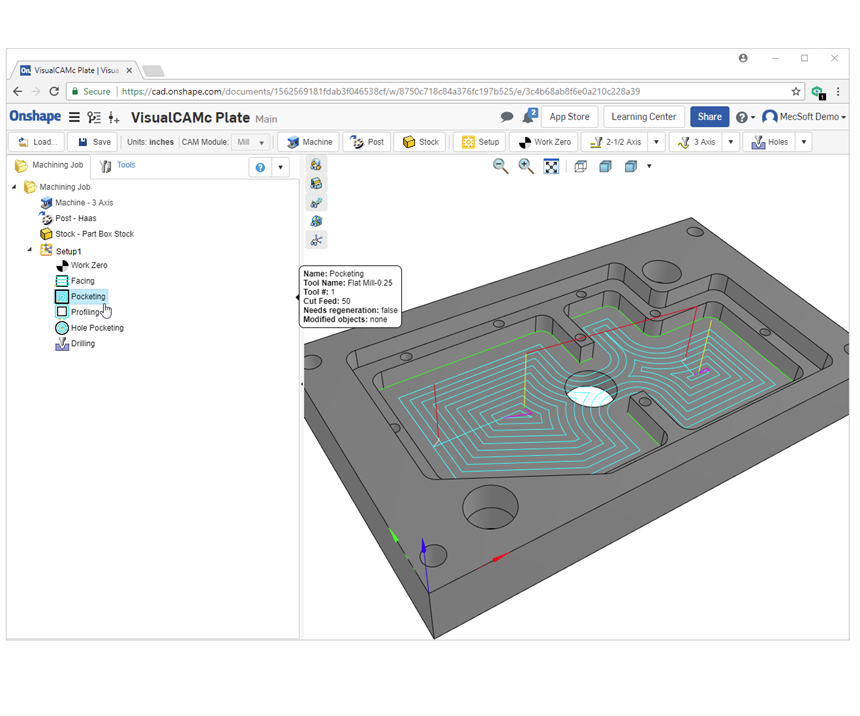

VisualCAM from MecSoft will enable users to instantly share and alter CAD/CAM files in a web browser through Onshape.

Drawing a sizable crowd to its booth at the Medical Design & Manufacturing West expo early in February, Onshape and MecSoft launched the public beta for VisualCAMc, a browser-based CAM software that utilizes cloud-based storage and sharing on the Oshape network. Designed to seamlessly integrate with MecSoft’s existing VisualCAD offering, this fully functional CAM software is designed to work on any browser and simplify the sharing of design files between those two specific CAD and CAM packages.

As the CAD programmer designs a part in VisualCAD, the part file is saved on the cloud, creating a unique, secure hyperlink to each iteration of the part design. Sharing the design with the machinist simply involves granting access to his or her Onshape profile. Once access is granted, the machinist can use the secure hyperlink to gain access to the part design, using the CAM software in the browser without ever having to download a file. With users on the other side of the globe able to access the designs remotely, there is no need to download, upload or catalog files. If the local computer crashes, the data from that session is not lost. If designers wish to return to older iterations, there is no need to search for the correct file.

The cloud-based platform further benefits from its open-source code. The companies encourage users to develop and share machining code with each other and make these crowd-sourced solutions available online. The goal is to provide better solutions as more users utilize the CAM software. Other ancillary benefits include the advanced security systems protecting the Onshape cloud and access to the company’s IT services.Related Content

-

Grinding Simulation Enables Growth in Custom Tooling

Simulation software both streamlines Gorilla Mill's grinding machine setups and speeds up the company's tooling design and verification processes.

-

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.