MC Machinery Systems Officially Opens New Headquarters

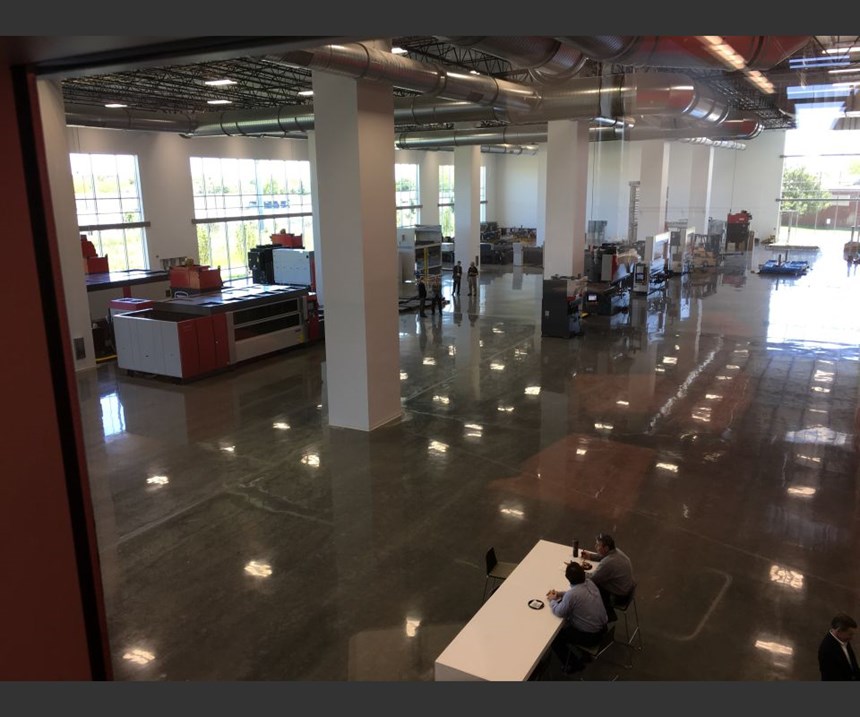

Last week, MC Machinery Systems Inc. officially opened its new, larger headquarters in Elk Grove Village. Cynthia Kushtush from sister publication Moldmaking Technology was there to cover it. Here is a small sampling of what she saw.

On June 30, 2016, MC Machinery Systems Inc., a subsidiary of Mitsubishi Corporation, announced its plans to build a new, larger facility in Elk Grove Village, Illinois. The announcement came with company representatives and partners from The Opus Group, Elk Grove Village and Heitman Architects overturning that first shovelful of dirt and, according to a few who were there, virtual reality headsets showing how the building would look when built. Well, last week they found out. MC Machinery Systems hosted an official ribbon-cutting ceremony with employees, partners and press (myself included) on hand.

"All of our competitors are located along Interstate 90 here," said Patrick Simon, marketing and corporate planning manager, during the opening ceremony. "You come out of O'Hare and this is the first building you see." He went on to explain that a gentleman from Ohio flew in to visit a competing EDM supplier, saw the MC Machinery signage on the building, and decided to stop in. "We did a demo for him, and I think we may have sold a machine."

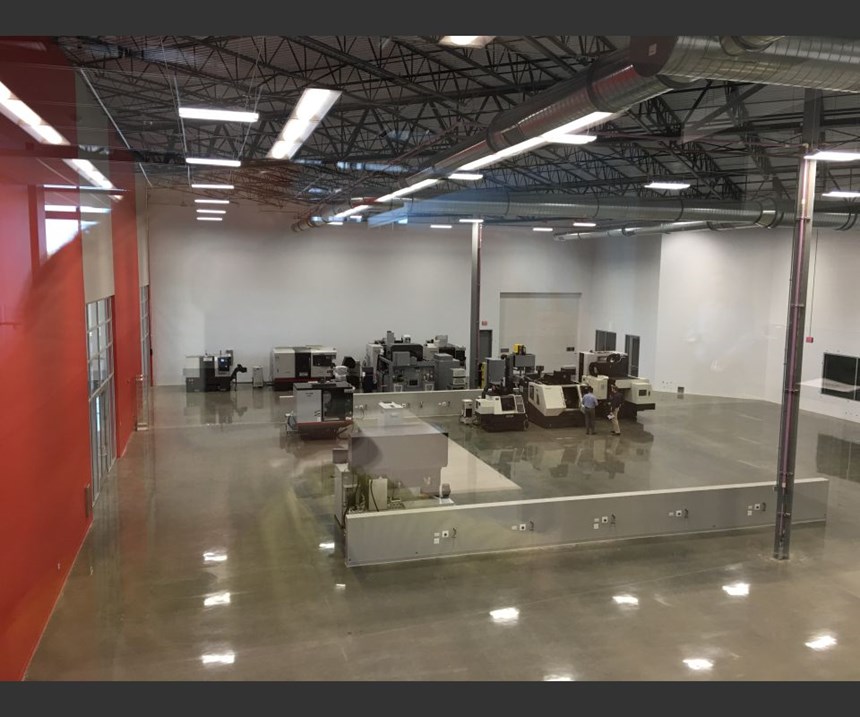

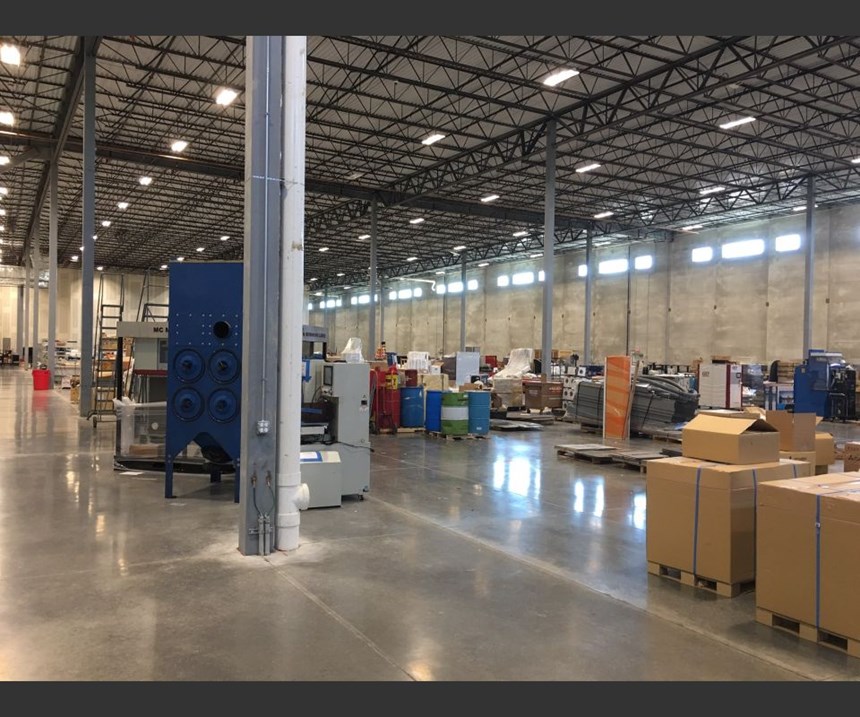

Above is a slideshow of highlights I put together after touring the new building. Mr. Simon said an open house event is in the planning stages for customers and others to visit, tour and see demonstrations of Mitsubishi EDM and laser, milling and turning, press brake and other machines. Take a look.

Related Content

-

Choosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

-

Choosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

-

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.