Published

MMS Chooses April 1st to Make Surprise Announcement

Despite virtually universal approval of Modern Machine Shop’s move to the larger “tech manual” size in September 2008, the magazine will return to its original digest size, pending approval of top execs at Gardner Publications.

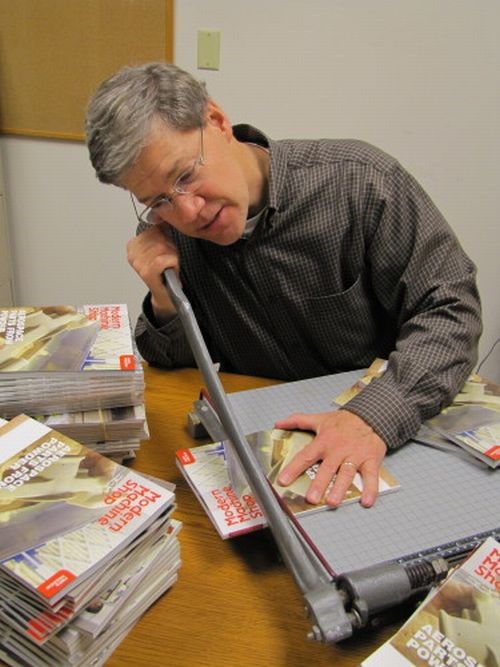

Editor-in-Chief Mark Albert cuts MMS back to its original digest size.

Despite virtually universal approval of Modern Machine Shop’s move to the larger “tech manual” size in September 2008, the magazine will return to its original digest size, pending approval of top execs at Gardner Publications.

Okay, we’re not really planning to change the size of the magazine again. That’s just an April Fools’ Day joke. The “top execs” at Gardner are still solidly behind the change in size that debuted almost two and a half years ago. However, after 32 issues, it’s worth assessing how well we’ve met our goals.

Our goals with the size change were to make the magazine more readable and more flexible while retaining a distinctively different format. The immediate response from readers was overwhelmingly in favor of the new size, with improved readability cited most often as the best-liked feature. Interestingly, many readers thought we had made the type size bigger to go along with the bigger pages. Not so. It’s still 9-point type. A different type style and more space between the lines make it easier on the eyes. Surprisingly, about the same number of words fit on the new size page as on the old.

Other changes in the graphic redesign have proven to be effective as well. You can tell what section of the magazine you’re in more easily, and it’s clearer what kind of content is being presented there. The flexibility in layout has been especially helpful when we adjusted editorial content accommodate the drop in advertising pages during the recent downturn. We never lost a healthy, vibrant look no matter how thick the issue was.

Of course, retaining a distinctive size was a smart idea. I can spot MMS on a shop manager’s desk, at a programmer’s station or atop a tool chest from 40 feet. Our subscribers always know when a new issue of MMS has arrived.

More importantly, though, we retained our focus on real-world metal working technology discussed from a decidedly shopfloor point of view. We want the content to be “readable” in the sense of being interesting, engaging and compellingly useful. A print magazine delivered monthly is still a great way to deepen understanding and convey wisdom. Other media channels may be more effective for finding facts and getting information, but print offers the self-paced discovery of fresh ideas and new concepts.

Of course, we are always looking for ways to improve the magazine and the MMS brand. The website where you found this blog has also been involving and improving. New technology zones, more video, better navigation tools and more.

The old issues of the magazine in the original digest size look really small to me now. I like the new size much better. Don’t worry—it’s not going to change!

.png;maxWidth=300;quality=90)