Nothing Boring about Boring

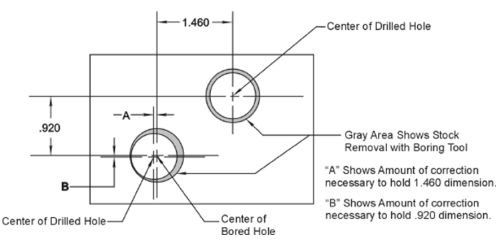

Under the right conditions, a precision boring operation can correct for a drilled hole that is slightly out of location.

Under the right conditions, a precision boring operation can correct for a drilled hole that is slightly out of location. That's one of the pieces of practical advice in "A Word about Boring Heads,” a short technical article by Criterion Machine Works. Boring equipment such as boring tools and heads are one of Criterion's specialties. The company knows a lot about boring operations and has captured some of this knowledge and wisdom in several articles on its web site.

For example, the article mentioned shows that the key to precision boring as a fix for an out-of-location whole is the ability of a boring head with single-point tool to remove more stock from one side of the hole than the other.

A companion piece, "A Word about Boring Tools," offers similar insights and recommendations. Its discussion about the importance of keeping the cutting edge of the boring tool on the exact centerline of the hole is clear and well-illustrated.

Related Content

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

-

Form Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

-

Walter Offers New Solid-Carbide Taps for Blind-Hole Machining

Walter’s TC388 Supreme and TC389 Supreme feature patent-pending cutting geometries that fully shear off the root of the chip when reversing, thus minimizing torque peaks.

.png;maxWidth=300;quality=90)