October Digital Edition Now Available

Modern Machine Shop's October digital edition is now available. This issue features emphasis topics of oilfield machining and multitasking machining.

The digital edition of Modern Machine Shop's October issue is now available.

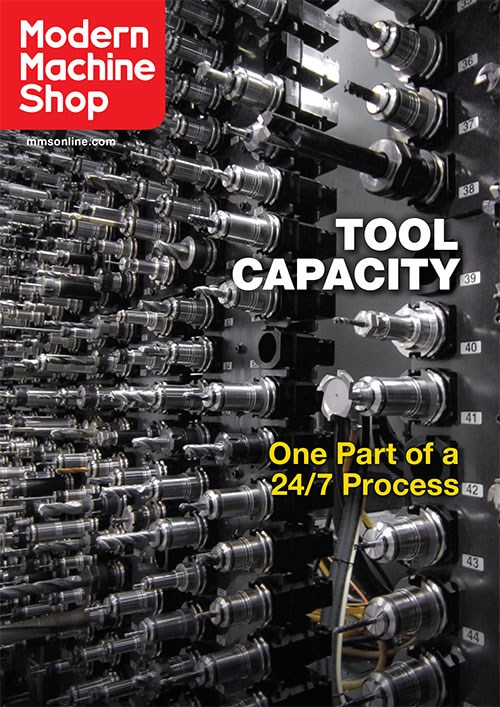

The digital October issue of Modern Machine Shop is now available. The cover story details how one shop established an effective process to run an HMC cell around the clock for applications in aerospace, oilfield and other industries. Another story discusses how one shop benefits from both portable metrology arms as well as standard CMMs. A third story will make manufacturers who are seeking skilled workers rid themselves of any misconceptions they may hold about hiring disabled individuals, especially those with specialized training. Finally, a fourth feature takes an in-depth look at tool monitoring for multitasking machines.

Our Rapid Traverse section chases after volumetric accuracy, links to a video that highlights extreme part-off demos, and explores a new concept for the programming and control of complex, multi-axis machine tools.

This month’s Better Production section includes case studies about cloud-based monitoring improving an aerospace manufacturer’s productivity, ERP software improving an aerospace shop’s operational efficiency, multi-pallet HMCs reducing setup times, and through-coolant capability reducing cycle time.

The Modern Equipment Review section highlights measurement and inspection products.

Related Content

-

3+3 Air Chuck Features Extended Stroke and Self-Centering

To keep up with the demands of the oil and gas industry, SMW Autoblok introduces BBFZA2G Air Chuck, featuring an extended stroke clamping range and three self-centering jaws.

-

4-way Bed Precision Lathe Features Automated Cycles

Long and thin workpieces can be machined without reclamping on this new machine from Weiler, according to the company.

-

Five-Axis Changes Weldments Into Monolithic One-Piece Parts

Moving from welding to five-axis machining enabled Barbco to redesign its weldments as monolithic one-piece parts with improved strength and repeatability.

.png;maxWidth=300;quality=90)