Emily Probst Former Senior Editor

Emily Probst was a senior editor for Modern Machine Shop (MMS), writing for the brand’s print and digital audience. Featured topic coverage included women in manufacturing, twin-spindle technology promoted at an industry open house event and machine shop maintenance.

Emily joined the Modern Machine Shop staff in the summer of 2006 as the editorial intern editing product releases for the International Manufacturing Technology Show (IMTS). Hired full-time in 2007 after graduating with a B.S.J. from Ohio University’s E.W. Scripps School of Journalism, she edited product releases and columns until 2012, when she moved to editing case studies. In 2016, she became Modern Machine Shop's managing editor, shepherding the production of the monthly print magazine, which is sent to 95,000+ subscribers. In this role, she also managed MMS’s blog as well as its LinkedIn, Facebook, Twitter and YouTube accounts.

In 2020, she became a senior editor, writing feature stories and original case studies for both print and online media channels. She also creates video content, offering behind-the-scenes expertise about how to submit a press release, as well as technical commentary and interviews on topics such as practical approaches to automation.

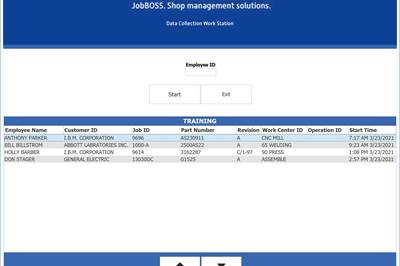

ERP Becomes a Communication Tool

Enterprise resource planning software modules provide at-a-glance understanding of job priority and location between departments as pandemic restrictions disrupted collaborative working environments.

Read MoreHow Advanced Grinding Technology Leverages Capabilities Beyond Grinding

United Grinding shows how rethinking traditional grinding technology and combining manufacturing processes can extend the role of grinding and make grinding machines more productive.

Read MoreAn Introduction to Superfinishing

Learn what superfinishing is, what applications it should be used for and why you should take care when specifying surface finish parameters.

Read MoreShifting From On-Machine to Offline Programming

In the midst of learning to program its CNC milling machines offline and the promise of using that experience to transfer more work to its Swiss-type lathe, an Ohio job shop is changing its company culture and taking on more complex work.

Read MoreJob Shop Automates Using Cobot Arm

Loading and unloading a repetitive job was straining employees at B.I.C. Precision Machine, so the shop integrated a cobot arm from Absolute Machine Tools into its production process.

WatchIMTS Spark: MMS Editors Choose Favorite Article of 2020

The editors of Modern Machine Shop share observations of reporting on metalworking facilities and their conversations with metalworking leaders.

Read MoreSupport Manufacturing with Your End-of-the-Year Contributions

The American Precision Museum is designing new, engaging exhibits available to all ages and accessible in person and on digital platforms. Be part of preserving industrial history.

WatchPractical Approaches to Automation

Automation isn't just useful for large volumes of the same part. Today, it is increasingly being used in machine shops for high-mix, low-volume jobs.

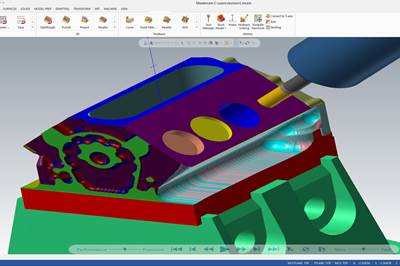

WatchCNC Machining and Manufacturing Students Find CAM Software Intuitive

A Lincoln College of Technology machining instructor details the most useful features of Mastercam — his school’s software of choice.

Read MoreWorkholding Considerations for Five-Axis Machining

Five-axis workholding isn’t just about applying technology; it’s also about applying a different mindset.

Read MoreSolid Construction and Fourth Axis Are Highlights of Shop’s Newest VMC

A vertical machining center with a fourth axis from Kent USA enables Mega Industries LLC to serve national laboratories quickly and accurately.

Read MoreCentralized Filtration Key to Company Growth

By investing in a Transor Filter System, Advanced Tooling Inc. was able to immediately improve cycle times and gain a consistent cutting environment.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)