Steady as She Goes

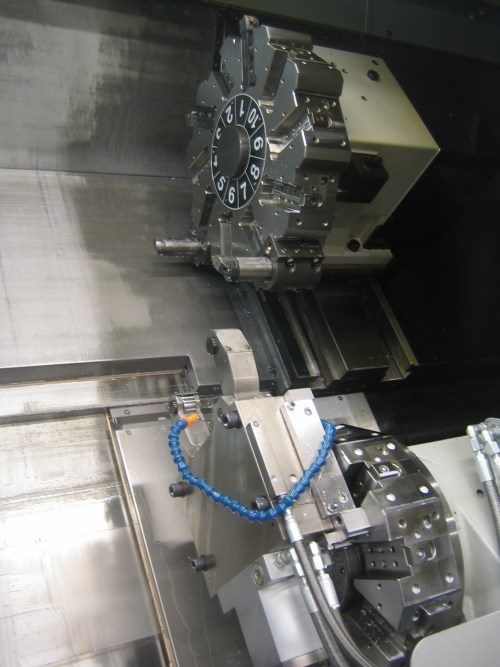

Machine shops are inventive operations. Learn how one uses a steady rest in a different way on one of its two-turret CNC lathes.

That shop’s owner offered a candid take on turn-mills, by the way. Integrating turn-mills was one of the most challenging endeavors his shop undertook (but he’s certainly glad they did it). Learn more in this article.

Related Content

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)