Thread Milling Explained

Watch this short video from Sandvik Coromant to learn about the advantages of thread milling.

Share

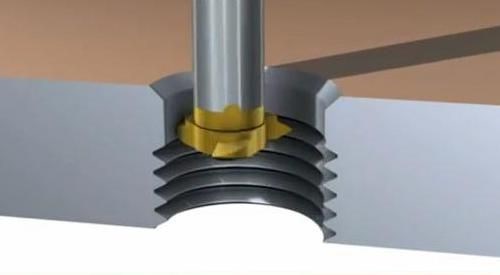

How can one tool cut threads into a range of different-sized holes? Answer: With thread milling, which uses helical-interpolation tool paths as an alternative to tapping.

Sandvik Coromant produced this short video on thread milling, describing its advantages and how to apply the technique. The video also describes how to program thread milling moves in Siemens NX CAM.

Related Content

-

Picking the Right End Mill

Kennametal global product manager Katie Myers explains how cutting tool features can impact machining strategies for different materials.

-

Maximizing Milling Operations With the Right Cutter

Selecting milling cutters that are suited to the task at hand can reduce cycle times, improve part quality and save money. Here’s where three milling cutters excel.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)