Threading Options for Hard Materials

Here are three approaches to threading hardened components.

Share

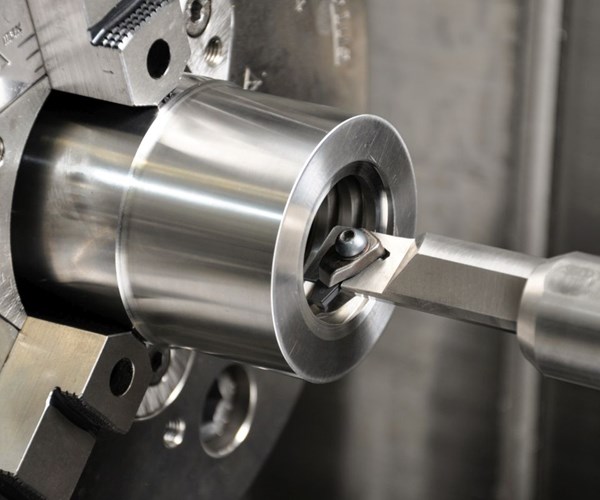

Threading hardened materials such as this one that requires an ACME thread presents a range of challenges.

Shops have options when it comes to hard threading. However, Seco Tools says most of them involve multiple operations and tools, each of which presents the risk of human error, a possible increase in cycle times and a probable hindrance of part consistency.

Here, the company highlights three such tooling options, along with their limitations:

1. A tungsten-carbide-tip insert brazed onto a steel, stick-type tool.

- Every tool change requires datums to be set again, which extends downtime.

- Material has to be annealed prior to machining and re-hardened afterward,which increases the risk of thread distortion.

- Tool life is short and cutting speed is typically limited to approximately 40 m/min.

- Long cycle times, often measured in days, occur because of multiple operations.

2. A brazed-tungsten-carbide or polycrystalline-boron-nitride (PCBN) grooving tool for roughing, and an insert made from either of those materials to finish profile.

- This time-consuming, two-tool operation requires annealing the workpiece if using the tungsten-carbide tool.

- The brazed tool joint needs coolant, and it limits cutting speed because of heat.

- Low cutting speeds extend cycle times (a 33-mm-pitch Acme thread can take as long as five hours).

- Rapid flank wear and built-up edge (BUE) occur due to low cutting speeds.

3. PCBN-tipped insert brazed to a steel shank.

- Every tool change requires datums to be set again, which extends downtime.

- The brazed tool joint needs coolant, and it limits cutting speed because of heat.

- Low cutting speeds extend cycle times (a 33-mm-pitch Acme thread can take as long as three hours).

- Rapid flank wear and BUE occur due to low cutting speeds.

Related Content

-

Maximizing Milling Operations With the Right Cutter

Selecting milling cutters that are suited to the task at hand can reduce cycle times, improve part quality and save money. Here’s where three milling cutters excel.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Eight Articles to Understand Live Tooling

A roundup of the most read articles about live tooling on Modern Machine Shop.

.jpg;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)