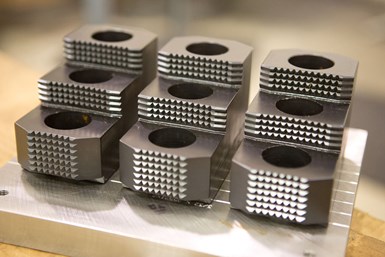

Dillon Manufacturing Provides Top Jaws With Custom Dimensions

Dillon’s custom, special or modified hard-, soft- or full-grip top jaws are said to be compatible with virtually any chuck manufacturer.

Dillon Manufacturing manufactures Custom Top Jaws in special widths to better grip workpieces and provide more part contact and penetration, with added length for better grip of small- to medium-sized parts. Incorporating multiple locating diameters enables machinists flexibility and the ability to changeover quickly. With the ability to grip a workpiece inner diameter (ID), outer diameter (OD) or a combination of both, Dillon Special Top Jaws securely grip parts without marring or marking the surface and in many materials to best suit the properties of the workpiece. Hard jaws can even be configured to accommodate several different diameters. Dillon’s standard and custom chuck jaws and collet pads and jaws are said to be ideal for high-speed machining, precision boring, tapping, drilling and finishing across all industrial markets.

Dillon says its custom, special or modified hard, soft or full grip top jaws are compatible with virtually any chuck manufacturer and are built with industry-best turnaround time. Tapered angle serrated surfaces that mirror the draft angle of the parts to be machined can also be designed.

Dillon has created a form online at https://dillonmfg.com/special-jaws/ that is designed for customers to easily order jaws with their exact desired dimensions.

Related Content

-

Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

-

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

.png;maxWidth=300;quality=90)