EAC's IoT Platform Connects Shop Floor With Actionable Data

PMTS 2023: The ThingWorx platform establishes a single source of data for collecting, aggregating and enabling secure and easy access to data for different job roles at multiple locations.

Share

EAC Product Development Solutions’ ThingWorx Internet of Things (IoT) platform provides a wide range of pre-built options that are designed to simplify industrial connectivity. With a library of more than 150 device drivers, client drivers, advanced plug-ins and connectors, it enables connectivity to thousands of devices and systems, establishing a single source of data for collecting, aggregating and enabling secure and easy access to data for different job roles at multiple locations.

Process engineers can rapidly view past events to enable comparisons and analysis. Teams can highlight problematic situations, identify trends and bottlenecks, as well as observe sequential events. With the process troubleshooter feature, users can decrease waste, unplanned downtime and associated costs.

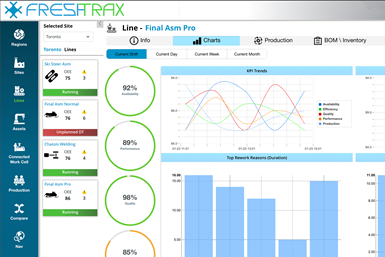

Real-Time Production Performance Monitoring (RTPPM) is an application that analyzes and visualizes key performance indicator (KPI) engine calculations for operational efficiency and to decrease unplanned downtime. View real-time data KPIs such as availability, performance, quality, overall equipment effectiveness (OEE), and other critical metrics in user-friendly visual dashboards with filters and drill-downs.

Easily accessible KPI data enables decision makers to spot weak points in manufacturing processes. At the same time, department and line leads can perform root-cause analysis quickly and effectively. Operators can see how they are doing and what is happening on the manufacturing floor with the operator landing page. According to EAC, RTPPM empowers organizations to be proactive with predictive maintenance, balance labor capital costs with production needs and increase flexibility and agility with real-time, data-backed decisions.

Additionally, ThingWorx automates the monitoring of asset properties and optimizes performance through connectivity. With the Asset Monitoring and Utilization (AMU) app, users can configure alerts based on property rules and limits, and better mitigate risk with an escalation process in case of unacknowledged alarms.

The Connected Work Cell (CWC) application shows station dashboards, charts and performance reports, along with secure file storage and document management. This feature supports operators with step-by-step work instructions and work order updates for increased productivity.

Related Content

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.png;maxWidth=300;quality=90)