Freedom IOT's Smart Manufacturing Platform Available in Modular Plans

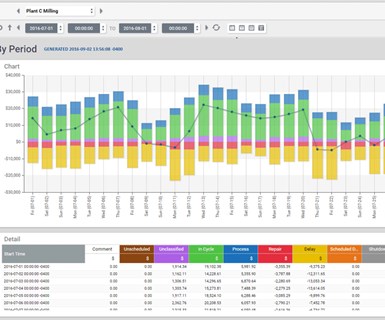

Freedom IOT’s Smart Manufacturing Platform, consisting of multiple modules, is designed to connect industrial assets of any brand, age or process and collect data into reports accessible from desktops, laptops, tablets or smartphones.

Freedom IOT’s Smart Manufacturing Platform, consisting of multiple modules, is designed to connect industrial assets of any brand, age or process and collect data into reports accessible from desktops, laptops, tablets or smartphones. The cloud-enabled Internet of Things (IoT) platform is available in three plan levels consisting of different moduels for shops to right-size the program to its needs.

The Light Plan includes Freedom’s eLog module, which provides machine or machine group filtering, configurable date/time ranges, flexible shift scheduling, machine strip chart, metrics reports, and machine alert Pareto charts. The eLog software suite connects machines and collects production asset data. Notifications are sent via email under the Light Plan.

The Pro plan includes all of the features of the Light Plan along with automatic part counting, overall equipment effectiveness (OEE) metrics, downtime event analytics, part production reports, program analytics, production category reports and tool reports. It also includes text message alerts and a factory income statement function from Freedom’s eScore financial module. The eScore module translates the data collected into dollars and effectively monetizes gains and losses based on user-defined parameters.

The Premium Plan includes all components of the Light and Pro plans with the addition of sensor data items, shift reports, real-time dashboards, slideshows and extended data modules for sensor analytics. Additionally, notifications can be set for condition-based triggers.

All plans include Freedom-developed MTConnect adaptors used to connect to CNCs, programmable logic controlers (PLCs) and robots, among other equipment.

Related Content

-

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Reinventing a Precision Shop With a Data-Driven Mindset

When this machine shop lost 90% of its business within three months, a reinvention was in order. Here's how it survived after quickly falling on hard times.

.png;maxWidth=300;quality=90)