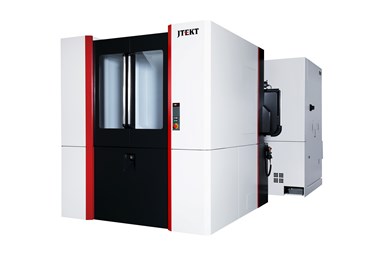

JTEKT Launches New Series of HMCs

The new FH5000 series machines include a 500-mm table capable of handling 1,000-kg loads.

JTEKT Toyoda Americas Corporation recently introduced its FH5000 series of three high-speed horizontal machining centers (HMC), including the FH5000S HMC with 800 × 800 × 880 mm (X × Y × Z) strokes, 900-mm workpiece diameter and 1,100-mm workpiece height capacity. The FH5000 series machines include a 500-mm table capable of handling 1,000-kg loads.

Toyoda's FH5000S HMCs with 60-tool ATC capacity are designed for speed and production reliability, featuring a 15,000 rpm, 50 hp (37 kW), 303 Nm (223 ft-lbs.) high-acceleration spindle. The 40-taper spindle is designed with four ceramic bearings at the front of the spindle for increased rigidity and reduced vibration. Its patented hydraulic preload system reportedly brings the spindle up to 15,000 rpm in less than one second without spindle warm-up, ideal for aluminum processing. The larger machines in the FH5000 series are equipped with a 50-taper spindle, 45 tools and a longer X-axis travel.

This machine is equipped with a direct drive B-axis table featuring an index time (90 degrees) of 0.7 seconds. The FH5000 machining centers with the spindle design, preload system and high torque features, enables machine shops to take advantage of more aggressive, high-volume machining in a compact footprint, according to the company.

Easily programmed, the H5000 series features the Toyopuc-Touch panel through which the operator can monitor the machine, see operating data including energy consumption and edit as required.

Related Content

-

Shop Replaces Two Verticals With One Horizontal

By trading two VMCs in to help finance the purchase of a new HMC, this shop was able to significantly increase production and move to lights-out machining.

-

The Job Shop Is the First Half of the Business

By day, NTL Industries went from a lathe and a mill in a home garage to an 11-employee enterprise in under five years. By night, it tackles a new future.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)