New Systems and Software Products from Modern Machine Shop, Feb. 26, 2021

The latest technology from Siemens Process Industries and Drives, Siemens Digital Industries Software, and Open Mind Technologies USA

Siemens Sitrans CloudConnect 240 Extends Digital Awareness

Siemens Sitrans CloudConnect 240 collects a second data stream from HART-based field devices, facilitating IoT solutions for the process industry.

Siemens presents its Sitrans CloudConnect 240 (Sitrans CC240) as a new IOT gateway for the process industry. The device establishes a second data channel, independent of the control system, which transmits data from HART-based field devices on Version 5 or later. This channel includes field-level data previously unavailable to the user — without adversely affecting the existing control technology. The system creates a direct connection between the field device and IT or the cloud, not only reading basic process values but also identification, configuration and diagnostics parameters. The system then makes this data available via an OPC UA server or the Siemens MindSphere IoT-as-a-Service solution.

Sitrans CC240 harmonizes data in line with the Namur Open Architecture information model. This creates a standard perspective on the installed base regardless of the technology and manufacturer, simplifying creation of digital applications for both on- and off-premise environments. This includes asset monitoring and management solutions, especially useful for smaller plants. Sitrans CC240 can connect to up to 64 devices and has an on-board, self-sufficient web server with configuration options and management views.

Connectivity options allow integration into existing systems. OPC UA transfers field device values and data directly to automation or IT systems, and the connection to MindSphere supports distributed use of several Sitrans CC240 systems — ideal for monitoring globally distributed assets on a central instance.

With Siemens’ Sitrans store IQ, users have an app for stock monitoring and management in production and logistics. Field devices measure filling levels of tanks, silos, racks or other storage facilities, then transmit the data via the Sitrans CC240 or familiar MindConnect gateways to Siemens MindSphere. Sitrans store IQ visualizes the acquired data and also generates alarms and events. For increased user knowledge, the app can also acquire variables such as temperature, pressure, humidity and binary inputs.

ThinkIQ Enhances Saas Manufacturing Platform Functionality

ThinkIQ has updated its software-as-a-service manufacturing platform with revised UI components, a richer type-and-system model and ValueStream Expressions for time series data.

ThinkIQ has updated its software-as-a-service (SaaS) manufacturing platform with product enhancements that include simplified analysis of time series data, reusable type systems that accelerate deployment and revised UI components that simplify construction of custom dashboards. The company says these added capabilities continue to build upon the software’s material traceability and insight — helping manufacturers improve yield, quality, safety, compliance and brand confidence while reducing waste and environmental impact.

This cloud-based platform is able to collect data inputs across the supply chain and identify correlations and root causes through the use of AI. It creates a new set of value-added traceability data, which is delivered with actionable insights to guide systems across the supply chain.

Updated functionality includes a richer type-and-instance system model that provides additional meaning to sensor data, enhancing repeatability and consistent analysis of data across many production units.

The upgrade also features ValueStream Expressions, a simplified approach to performing calculations on time series data that still acknowledges the complexities of sensor data processing. These expressions include manufacturing-specific functionality such as material flow alignment of the data, rich interpolation algorithms and unit-of-measure conversion. ThinkIQ says ValueStream Functions can process time series data at its full resolution with no need to downsample or resample the data prior to performing calculations.

This new update also overhauls ThinkIQ’s UI components, which now allow people with simple web development skills to build rich dashboards and user interfaces. The UI components integrate into ThinkIQ's content management system and embrace ThinkIQ's type-and-instance system model so users don't worry about mapping UI components to the underlying data.

Latest Siemens Parasolid Update Enhances Convergent Modeling

Siemens has updated its Parasolid software with enhanced convergent modeling functionality, also including substantial updates for boundary representation (B-rep).

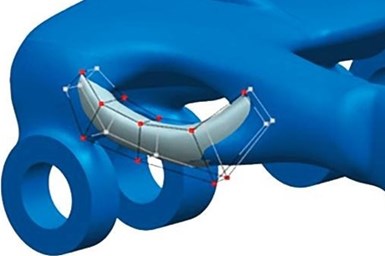

Siemens Digital Industries Software has updated Parasolid, its open software technology for geometric modeling. The latest release expands on convergent modeling for generative engineering, 3D-printing and reverse engineering applications, adding new tools that integrate previously incompatible facet and boundary representation (B-rep) data formats within a single modeling session. Siemens says this enhanced support for mixed models can help drive significant productivity gains by eliminating the need for time-consuming model conversion and allowing users to apply classic design techniques directly to facet models.

Parasolid’s update also allows it to add further value to design and engineering workflows in many different applications by allowing users to intersect meshes with all classic B-rep surface types and perform more sophisticated configurations of fillets and chamfers on mixed models. In addition, there are new tools for direct editing of faces and for rendering and repairing mixed models. The update also enhances B-rep in areas such as blending, sweeping, non-uniform scaling and rendering, bringing users gains in modeling flexibility and performance.

Siemens uses the Parasolid geometric modeling kernel in its own Solid Edge and NX software, and it serves as the core of the Xcelerator portfolio’s open and flexible ecosystem. The company also says Parasolid is used in over 350 other applications from industry-leading CAD/CAM/CAE/AEC software vendors.

Red Lion Controls Expands SixTrak RTU Line

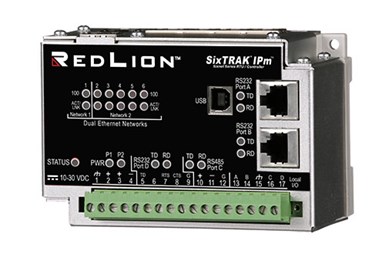

Red Lion Controls has added the ST-IPm-8460 to its SixTrak line of industrial RTUs. The company’s Red Lion Workbench software powers the device.

Red Lion Controls expands its SixTrak line of industrial remote terminal units (RTU) with the launch of the ST-IPm-8460, which operates on the Red Lion Workbench platform with an IEC61131-3-compliant editor and runtime engine. Red Lion says it designed the new RTU for applications that need increased processing and communication speed and storage, while maintaining the flexibility and reliability that customers require and expect from Red Lion to monitor and control equipment. The ST-IPm-8460 has achieved UL Class I, Div 2 certification and an ABS listing, while the construction supports operating temperatures from -40°C to 70°C, allowing the RTU to operate in harsh and hazardous locations.

The company says the combination of ST-IPm-8460 and Red Lion Workbench can support large, complex projects across multiple devices. Red Lion Workbench provides customized control, standard language support, debugging and monitoring tools, project automation and controller redundancy. The ST-IPm-8460, for its part, is available for configuration using Red Lion’s EtherTrak-2 I/O modules to scale its functionality to the user’s application.

Red Lion’s ST-IPm-8460 also offers private labeling as well as dual power inputs and support for redundant Ethernet networks to increase uptime, while a multitude of communication ports and supported protocols enable connectivity to a variety of field devices.

Open Mind Updates HyperMill CAD/CAM to 2021.1

Open Mind’s 2021.1 HyperMill update includes features that give programmers unprecedented control and flexibility, like editing toolpaths after generation.

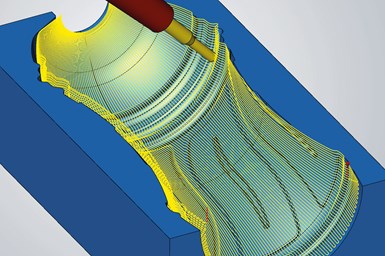

Open Mind Technologies AG has updated its HyperMill CAD/CAM software suite to version 2021.1, introducing new and enhanced features for 3D, five-axis and mill/turn machining. Key innovations include a new Interactive Edit Toolpath capability that enables toolpath editing after initial generation. The company says the ability for programmers to adapt toolpaths by trimming and removing sequences for component conditions should be useful for optimizing tool and mold making.

HyperMill 2021.1 now offers an import function that retrieves face quality information and metadata when importing CAD data from neutral or native formats and attaches data to the imported faces in HyperCAD-S, making the information available to HyperMill and its machining processes.

A new five-axis radial machining strategy allows programming bottle shapes and similar cavities in HyperMill, resulting in high-quality surface finishes. Joining this strategy is a new radial projection method that calculates toolpaths and applies the most productive possible machining strategies. During five-axis machining, HyperMill can also apply its High-Precision Surface Mode and Smooth Overlap strategies to ensure optimal surface quality and clean transitions.

HyperMill 2021.1 also offers several enhanced multi-blade strategies. The new strategies allow the use of any number of surfaces for the suction and pressure sides, simplifying the process of extending blade surfaces, and the flank-milling strategies result in smaller deviations on the suction and pressure side.

The software update also supports fillets with a variable radius and integrates a new, powerful Simulation Center for generic NC data in turning and milling operations. The Center enables faster simulation, independent collision checking and extensive analysis functions.

Additional new features in HyperMill 2021.1 include an XY Optimization command for 3D profile finishing, an Align Best Fit command to match components with like-geometry and integration between the Mill-Turn Module’s high-performance mode and three-axis simultaneous roughing strategy.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)