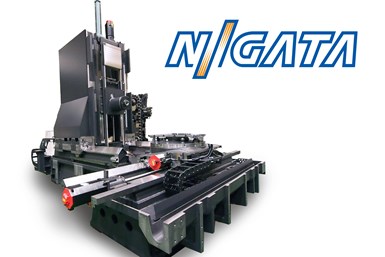

Niigata Launches HMC With Hardened, Ground Inverted V-Shaped Slideways

According to Niigata, the HN800-V is built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances.

Niigata Machine Techno USA Inc.’s HN800-V horizontal machining center (HMC) is said to offer the performance of a high-speed jig borer with minimal investment increase over traditional HMC’s.

Niigata says the HN800-V is built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances. The HN800-V is reportedly the world’s first machining center to feature hardened and ground inverted v-shaped slideways; it can achieve volumetric accuracy of .00005" per foot. The v-shaped slideway system converts the weight of the column unit into restraining force on the sliding unit. This restraining force provides superior stability, long-term axis straightness of motion that virtually eliminates pitch and yaw motion. The combination of hand-scraped slideways and hardening-processed slide guides is said to maximize the machine’s durability.

The V-shaped slideways, consisting of anti-abrasion material, also contribute to the high-speed performance of the machine; it is capable of achieving rapid traverse of 50 m/min (1968 ipm).

For extreme stability, this v-shaped slideway machine features a solid meehanite cast iron frame with extensive ribbing. Further contributing to precision performance is a powerful and rugged geared high torque spindle. It is constructed with seven sets of wide-spaced, super precision angular contact and roller bearings. The spindle head stock uses a mono-cast (single piece) casting to achieve heavy and powerful milling capability and greater stability than bolt-together type spindle heads.

The HN800-V’s pallet clamping system uses a stable clamper plate to ensure optimum down force and increased clamping forces of the pallet during extreme cutting conditions. Jets of air discharge from the tapered cones when the pallet is changed to ensure proper clamping and to cleanse seating surfaces.

The HN800-V offers 1530mm (60.2") x-axis travels, 1230 mm (48.4") y-axis travels, 1020 mm (40.2") z-axis travels and a b-axis rotary angle of 360,000 positions. Maximum workpiece swing diameter is 1750 mm (68.9"), which Niigata says is the largest work envelope in its class. Maximum workpiece height is 1400 mm (55.1").

Related Content

-

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

-

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

.png;maxWidth=300;quality=90)