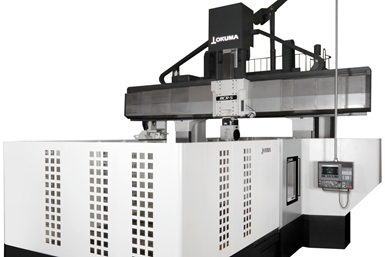

Okuma’s MCR-S Roughs, Finishes Press Dies in One Setup

Okuma's MCR-S double-column machining center reduces cycle time to rough and finishing press dies in one setup.

Share

Okuma America Corporation has debuted its new MCR-S double column machining center that roughs and finishes press dies in one setup. It features full five-face and five-axis machining and is suitable for die repair work and heavy-duty machining of process-intensive press dies.

The MCR-S is designed to accommodate a range of stamping die requirements, making it well-suited for the automotive and aerospace industries. It can handle hardened cast iron, nonferrous and exotic materials.

The machining center achieves maximum productivity and accuracy through various intelligent technologies and innovations. The one-setup process reduces cycle time by using faster cutting feed rates and spindle speeds, and eliminating the process-intensive steps of manual finishing. Innovative die-alignment processing also reduces concave/convex die-alignment times, according to the company.

Okuma’s Thermo-Friendly technology reduces heat in the machining process and compensates for any ambient temperature changes, allowing for continuous long runs of cutting without comprising accuracy, while the Hyper-Surface feature detects and automatically compensates surface disturbances in the part program to eliminate streaks or stripes for a high-quality surface finish.

Related Content

-

Five-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

-

How a Family-Owned Tooling Company Competes with Global Giants (Includes Video)

Not ready to go digital? Consider this: With Siemens NX ecosystem, precision shop D’Andrea cut its programming time by 50% and is able to compete globally—even against industry giants.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-02.jpg;maxWidth=728;quality=90)

-02.jpg;maxWidth=300;quality=90)

(1).png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)