SprutCAM's Mobile App Quickly Calibrates Robot Movements

The Robot Calibration mobile app helps users find the exact position of the tool tip, which can then be used as a reference point for the robot’s motion control system.

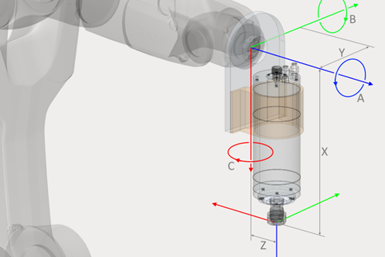

SprutCAM Tech’s Robot Calibration mobile app is designed to accurately calibrate the tool center point (TCP) and automatically transfer the data to SprutCAM X Robot via a smartphone.

TCP calibration is a process used in robotics to determine the position of a tool relative to the robot’s arm or body. This information is critical to ensuring the accuracy of the robot’s movements and the precision of its tool operations. The goal of TCP calibration is to find the exact position of the tool tip, which can then be used as a reference point for the robot’s motion control system. This enables the robot to consistently and accurately perform tasks such as cutting, drilling and welding in the correct location. The calibration process typically involves measuring the positions of various points on the tool and using these measurements to calculate the position of the TCP.

The latest version of SprutCAM Tech’s Robot Calibration app now supports TCP calibration for the following robot brands: FANUC, Kuka, CRP, Denso, Dobot, Estun, Hiwin, Hyundai, Motoman, Newker, Manutec, Nachi, OTC Daihen and Turin.

SprutCAM Tech’s app uses the double spikes method for calibration, which is used in robotic and machine tool applications. It consists of measuring two points on a probe and calculating the position of the tool center point based on these measurements. The purpose of TCP calibration is to determine the location of the TCP with respect to the robot’s base coordinate system so that it can be accurately positioned for machining or other operations. According to SprutCAM, the double spikes method can be useful in situations where the probe is unable to measure the tool position at the exact TCP. The double spikes method follows these steps:

- Measurement of the position of the long tool. The position of the tool is measured at different joint angles or at different positions along the robot path.

- Measurement of the short tool position and automatic determination of the tool orientation.

- Automatic recognition with optical character recognition (OCR) and reading of the data by the Robot Calibration application and calculation of TCP coordinates.

- Transmission of TCP coordinates to MachineMaker using a QR code.

The Robot Calibration mobile app reportedly enables SprutCAM X Robot software users to eliminate errors caused by manual data entry, reduce robot debugging time and no longer need for expensive calibration tools or services.

Related Content

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

View From My Shop Video 1: A Deep Dive Into Automation with Advance CNC

Advance CNC leverages multiple forms of automation to increase its milling machines' productivity. Learn more in this episode of The View From My Shop.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

.png;maxWidth=300;quality=90)