Die/Mold

The Progress of a Progressive Die Maker

This shop sees no long-term threat in the reality of lower prices. Machine tool investments related to various die components allow the shop to use skilled labor more efficiently.

Read MoreWhen to Mill Keeps Changing

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

Read MoreVideo: The Role of Heat in High Speed Machining

In high speed machining of die/mold steels, the heat has a more beneficial effect than the role it plays in conventional cuts.

WatchAluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

WatchThe Momentum Behind Aluminum Tooling

A growing number of OEMs are looking to aluminum production molds in order to reduce tooling costs and speed new product time to market. Opportunities exist for shops poised to manufacture such nonferrous tooling.

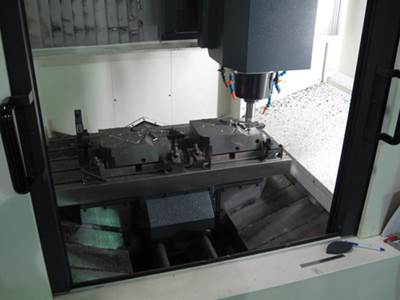

Read MoreFive-Axis Jig Borer For Die, Mold Manufacturing

Designed for high-precision die and mold machining, Yasda’s YBM-Vi40 five-axis jig borer is said to reduce machining time of complicated shapes in extremely hard materials. The jig borer can tilt the workpiece to reduce cutter length requirements, which enables feed rates of 2,000 mm/min.

Read MoreWhat’s Ahead For The North American Auto Industry

Here are highlights from a presentation by an auto-industry observer at Makino’s recent technology expo.

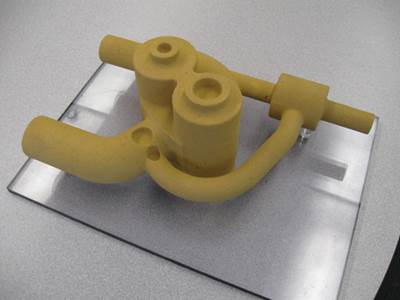

Read MoreStraight to Sand

Through direct CNC machining of molds and cores, this supplier of cast and machined parts skips the pattern-making step that would otherwise be fundamental to casting. The result is weeks of lead-time savings for complex parts that are needed in a hurry.

WatchMilling Tool Line Features New Insert Size

Iscar’s Helido Upfeed line of high-feed milling tools now includes the H600 WXCU 0403 insert, which is designed for 16- and 20-mm-diameter tools. (The complete milling tool line features diameters ranging from 0.

Read MoreShrink-Fit Covers Carbide, Steel, HSS Shanks

Kennametal offers a shrink-fit toolholding system for machining centers and multi-tasking machines. The program is split in two lines: general purpose (GP) and high torque (HT).

Read More.png;maxWidth=970;quality=90)