EDM

EDMing Beryllium Copper: An Introduction

Beryllium copper offers many benefts to the moldmaker and plastic injection molder, yet questions remain on how to best EDM it, which alloy to specify, where to use it, and is it safe to work with?

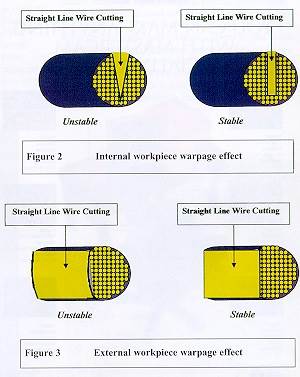

Read MoreCryogenic Treatment Enhances Stability For Wire EDM Operation

In the world of Wire EDM professionals, the mission is very similar to NASA's, in minimizing scrap rate and in maximizing quality (i.e. meeting customer specifications). That is the challenge to each Wire EDM operator and tool designer.

Read MoreReaching New Depths And Greater Accuracy

Just when you thought high speed machining or hard milling would steal the best applications from ram-type electrical discharge machines, linear motor technology is taking "sinker EDM" to levels unattainable with any other metal removal process.

Read MoreWhere Wire EDM Is A Workhorse

This shop finds the process practical, productive and predictable, an indispensable technology that supports all of its manufacturing capability.

Read MoreEDM vs. Milling In Die/Mold Machining

In many die and mold shops, the choice between ram EDM and CNC milling is far less clear than it used to be. Changing technology is changing the rules.

Read MoreSilicon Powder Additives Proven Safe And Effective In EDM

As with any new EDM innovation, the effectiveness of various powder finish processes will be debated. Likewise, dual-tank systems will be compared to single-tank systems. Here's a viable answer to that debate.

Read MoreTrends In EDM

Electrical discharge machines, both wire and ram type, have undergone rapid improvements in capability, economical operation, speed and flexibility. New applications are continually emerging as shops discover the advantages of this process.

Read MoreThe Case For Additive Technology In EDM

Producing fine finishes on EDMed surfaces has long been a goal, especially for mold and die shops that operate ram-type electrical discharge machines. Lately, there has been renewed interest in using additives in the dielectric oil to achieve ultra fine finishes with graphite electrodes without excessive burn times.

Read MoreMethods' Revamped Lineup Features Advanced Technology

“Smart” machine tools. Spindles reaching 60,000 rpm. Affordable robots for load/unload.

Read MoreHigh-Precision Mold Shop Cuts EDM Machining Time By 40 Percent

Finally tiring of the tedious cutting times, marginal finishes and excessive secondary operations coupled with automatic wire feeder problems, this mold shop owner sought-and found-an alternative.

Read More