qualitygagingtips

Measuring Tools Basics: Faster and Better

In a high-volume production environment, the cost of inspection is related to the speed with which measurements can be made and interpreted.

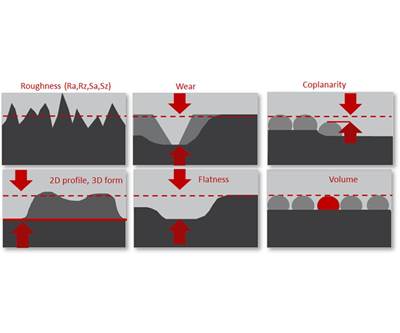

Read MoreMeasurement for True Surface Analysis

Optical metrology is providing more information, faster, about surfaces that were once impossible to measure and understand.

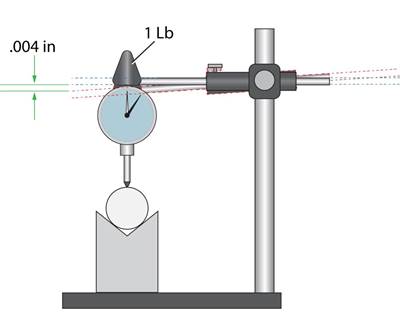

Read MoreWhy QC Inspectors Should Consider Gaging Fixture Spring Rates

All fixtures for part gaging will have some amount of deflection or spring rate that can affect measurement accuracy. A better understanding of spring rate can enable quality control inspectors to detect and eliminate this possible error source.

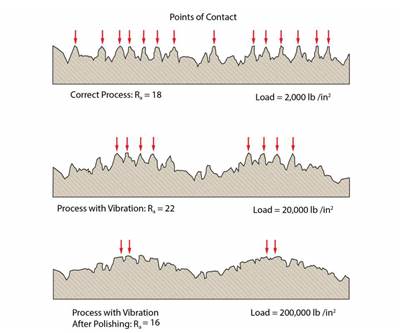

Read MoreSetting a Roughness Goal and Meeting It

Subjective surface finishes have no place in today’s high-precision manufacturing environment.

Read MoreDial vs. Test Indicators

Dial and test indicators are close cousins. They are both mechanical magnifying devices used for dimensional comparison.

Read MoreWhat Do Manufacturers Really Know About the Surfaces of the Parts They Are Producing?

Knowing only the average roughness may not be enough. Other surface parameters can affect product quality.

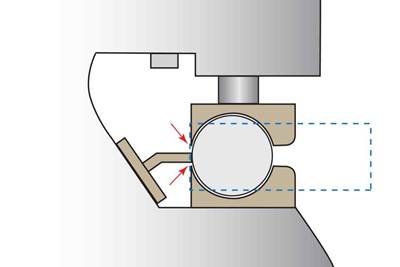

Read MoreJust This Once, You Can Blame the Gage

Even the old, reliable gage is subject to wear. George Schuetz, director of precision gages at Mahr inc., gives guidance for machinists to maintain their gages.

Read MoreDocumenting Your Data Collection

Industry 4.0 helps tie gaging equipment data with part measurement for 100 percent traceability.

Read MoreLess Is More with Dial Comparators

Why use a dial indicator with more than the needed range? A dial comparator offers less risk of misreading the dial without the cost of an electronic gage.

Read MoreMicrometers – Shifting into High Gear

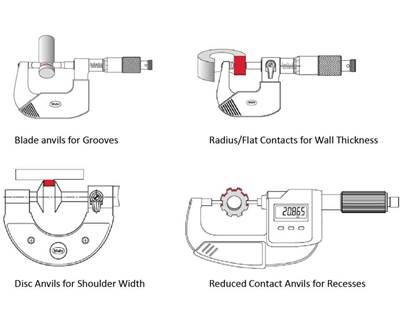

Over time, the basic handheld micrometer has evolved to include numerous contact point configurations and digital electronics. But in 150 years, the micrometer is still one of the most popular and versatile precision measuring tools on the shop floor.

Read More

.png;maxWidth=300;quality=90)