Five-Axis

Taking It Slow Pays Off for Learning Five-Axis Machining

A deliberately incremental approach helped this shop flatten a significant learning curve for collaborating on the postprocessor, easing setups and using cutting tools effectively.

Read MoreIncrease Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

Read MoreFive-Axis Blends Require Minding Ballnose Tolerances

Proper symmetry, expressed via the end mill’s diameter and radius tolerance, is critical to ensure smooth surface finishes during five-axis contouring operations.

Read MoreVideo: Accelerated Blisk Milling

CAM and cutting tool companies develop a process for machining a titanium bladed disk in less than half the conventionally expected cycle time.

WatchMulti-Function Machines Turn, Mill and Grind

MCM offers a range of four- and five-axis machines, as well as multitasking machine models that can turn, mill and grind.

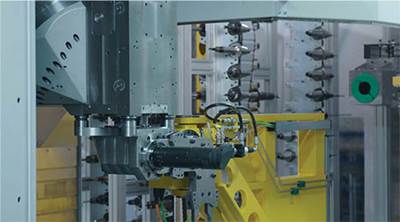

Read MoreTechnology for Turning on a Five-Axis Machine

A turning tool adapter that mounts to the MCT five-axis machine isolates the main spindle bearing from the shock of turning operations.

Read MoreDecember 2015 Product Spotlight Slideshow: Machining Centers

This month’s Modern Equipment Review Spotlight focuses on machining centers.

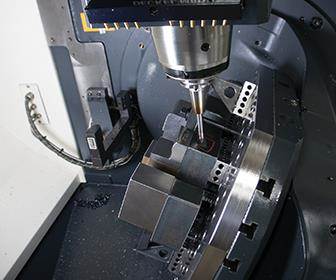

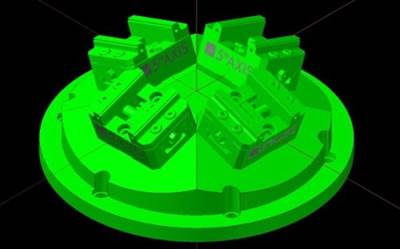

Read MoreFive-Axis Machining for Multi-Part Processing

Several parts at various orientations in one setup create what would seem to be a programming challenge, but control features make this cycle simple to create.

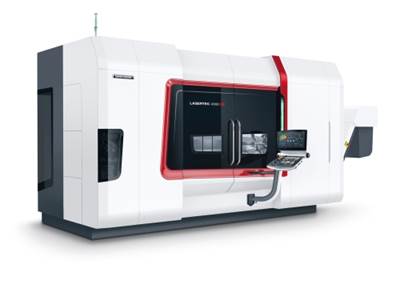

Read MoreHybrid Machining Center Intersperses Milling with Growing Parts

DMG MORI’s Lasertec 4300 3D hybrid machine incorporates additive-directed energy deposition (blown powder) into a five-axis turn-mill machining center with a working area of 600 × 1,500 mm.

Read MoreDual, Linked Five-Axis Mills Efficiently Cut Composites

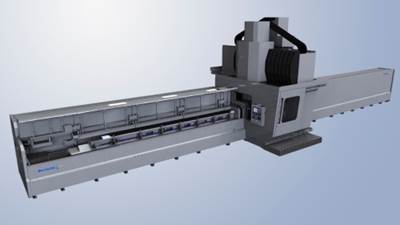

The Bertsche Dual P5 mill comprises two independent, but linked, five-axis machining modules (A side and B side), each with separate machining chambers, enabling shops to machine two different parts at the same time while taking up the same overall size as the company’s single five-axis P5.

Read More

.jpg;maxWidth=300;quality=90)