CNC & Machine Controls

Real-Time Tool Monitoring

Machine operators have long dreamt of a process monitoring system that detects tool wear, and potentially catastrophic conditions and automatically compensates for changes in tool geometry after resharpening. Now that dream is a reality.

Read MoreKnow Your Control

A new training center will enable Heidenhain to support its CNC users by ensuring that they are aware of all that the control can do. The value of some control capabilities don’t become apparent until they are seen in use.

Read MoreDocumenting within CNC

Including messages directly in the program can help operators run it accurately.

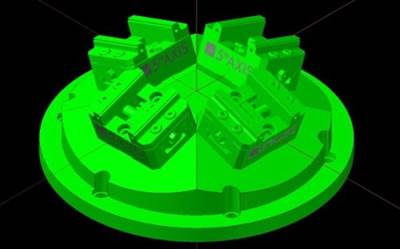

Read MoreFive-Axis Machining for Multi-Part Processing

Several parts at various orientations in one setup create what would seem to be a programming challenge, but control features make this cycle simple to create.

Read MoreCNC Enables Four-Axis Turning without CAD/CAM System

The expanded contour machining cycle for Siemens’s Sinumerik controls now facilitates four-axis turning on lathes, enabling two turning tools, opposite one another, to machine a workpiece simultaneously for reduced machining time.

Read MoreCNC System Can Be Customized for Three Different Operators

Okuma America introduces OSP Suite, an open-architecture CNC system that combines the company’s “Intelligent Technologies” with various software applications to improve cycle and lead times while achieving optimum machine conditions.

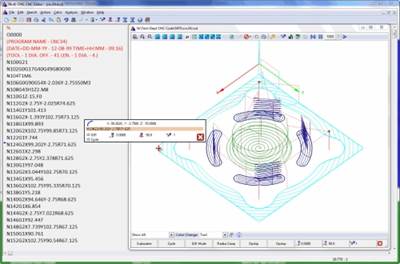

Read MoreCNC Editing Software Enables Off-Line CNC File Management

Spectrum CNC Technologies offers a stand-alone version of its Multi-DNC editor, backplotter and file compare software, which includes the same CNC editing and viewing features integrated within the Multi-DNC package, but for a stand-alone PC.

Read MoreDetecting Chips in a Milling Spindle

Chips in a milling spindle can subtly deform a tool assembly until the cutting tool is out of alignment. Grob's chip-in-spindle detection system detect stresses that may indicate chip interference.

Read MoreRotary Encoders Employ EtherCAT Technology

The Leine & Linde PSE and PHE 900 series of rotary encoders, available from Heidenhain, are designed for heavy-duty applications and are now available with an EtherCAT interface option.

Read MoreControlled Welding Process Joins Metal in a Flash

Manual methods were not accurate enough for joining advanced high-strength steel (AHSS), so Taylor-Winfield Technologies worked with a Rexroth distributor to devise a technique using a motion controller and hydraulic drives for better precision.

Read More

.png;maxWidth=300;quality=90)