A Vise Designed With CNC Machines In Mind

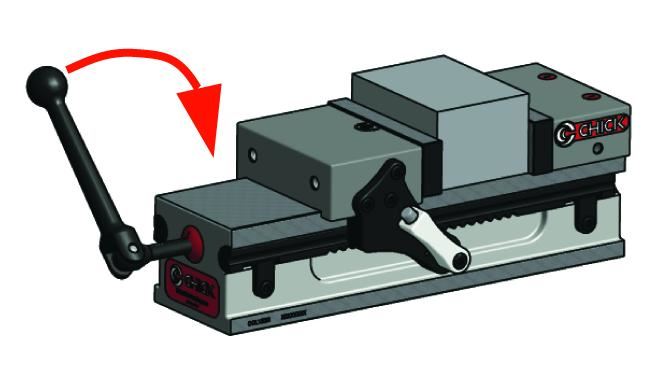

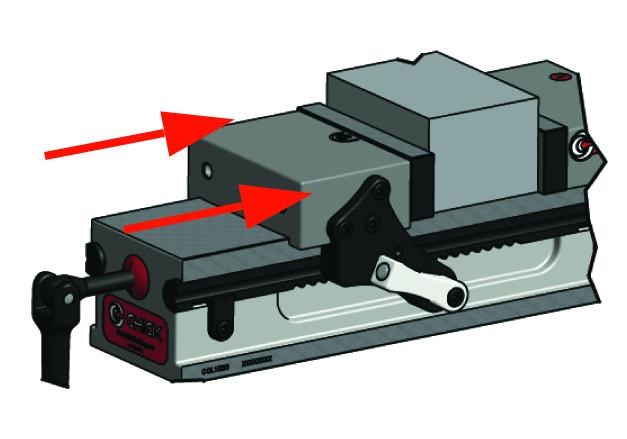

A sliding, locking mechanism allows users to quickly push this vise’s moveable jaw close to the workpiece before tightening the wrench. This minimizes the number of wrench turns to secure the part and allows users to quickly clamp parts of various sizes.

Share

A common first step for shops searching for ways to speed and simplify setups on their CNC machines is a careful examination of existing workholding methods. Depending on the situation, an alternate workholding device might reduce spindle downtime by minimizing the time needed to load/unload parts and set up a new job. To that end, Chick Workholding Solutions (Warrendale, Pennsylvania) has developed a single-station vise based on input from end users that is said to mirror the versatility and speed of modern CNC equipment.

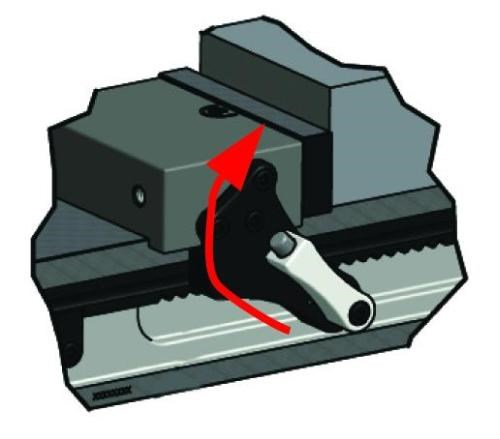

The One-Lok vise, which provides up to 10,000 pounds of clamping force, has one fixed jaw and one moveable jaw. A sliding, locking mechanism allows users to quickly push the moveable jaw close to the workpiece before tightening the swivel wrench (see drawings). This minimizes the number of wrench turns needed to secure the part and allows users to clamp parts of various sizes and shapes quickly and easily. An optional work stop that attaches to the side of the vise can be used for repeated part positioning.

The vise’s BoltFast jaw system allows users to switch between hard jaws and machineable soft jaws with just a partial turn of two setscrews using a T-wrench (the design doesn’t use long jaw bolts). Each setscrew drives a locking slide that matches a profile machined into the back of a jaw to secure it to the vise. Partially turning the setscrew counterclockwise loosens the jaw, while a clockwise turn locks it into position. Jaw changes can be performed in seconds.

The vise has a sealed, solid base that enables easy cleaning with a blast of shop air—its base doesn’t have a valley into which coolant and chips can collect. Rails along either side of the base allow toe clamps to position and mount the vise on a machine’s table. The vise can be moved to a new location on the table by simply loosening the toe clamps and sliding it across the table. In addition, pilot holes machined in the underside of the base allow the vise to be located on the table via pins.

The One-Lok vise is currently available in a 6-inch jaw-width version that offers holding capacity of 8 inches at maximum jaw opening.

Related Content

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.