AI Servo Tuning Explained: How CNC Machines Optimize Motion Automatically

What FANUC calls AI Servo Tuning is changing how machines behave before their first cut — even though most machinists will never touch it.

Share

What FANUC calls AI Servo Tuning is changing how machines behave before their first cut — even though most machinists will never touch it. The technology works behind the scenes to improve surface finish, contour accuracy and consistency between “identical” machines. In practice, it can resolve certain finish defects in minutes rather than days.

The surprising part? You may never interact with the tuning routine directly. There are no new features to learn, no software to install, and no workflow changes for programmers or operators. Yet its impact is visible on the shop floor: smoother contouring, cleaner finishes, fewer unexplained marks in the part and less downtime after service.

At its core, the technology influences whether a new install “just works.” It determines whether two identical machines cut the same or how quickly surface finish or accuracy problems get resolved after the machine has been serviced.

I recently sat down with Rick Schultz, Aerospace Program Manager for FANUC America, who works extensively with automated and AI-assisted motion-control tuning systems in aerospace machining applications. Here’s what I learned and why this technology matters.

Why Servo Tuning Exists

Every CNC axis responds to motion error with a defined level of aggressiveness. Corrections that are too aggressive risk overshoots, oscillations and chatter. The opposite problem — under-correcting — risks slow or inaccurate contouring. A properly tuned servo system hits the sweet spot, offering balanced responsiveness and stable cutting.

Most major control builders offer some type of auto-tuning. But until recently, these routines were only good enough to get a machine running rather than cutting at a high level. For precise finish and contouring work, someone with deep experience in motion controls still had to finish the job manually. In our industry, these experts developed an almost mythical status — “servo tuning magicians” — who can analyze gains and filters, make a few adjustments or recite a few incantations and, presto, the part is back in compliance.

AI-assisted servo tuning doesn’t replace those experts; it just turns their magic (a.k.a institutional knowledge) into a repeatable playbook.

Less Magic, More Logic

AI Servo Tuning is not a button to push when you hear chatter. It’s a tool for machine builders, distributors and service technicians — the people responsible for commissioning and supporting machines.

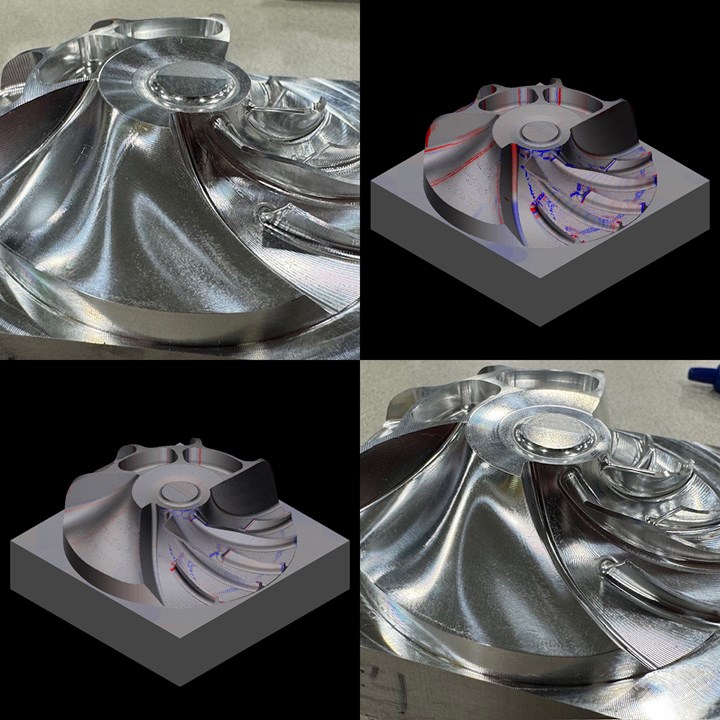

This four-image sequence illustrates how AI-assisted servo tuning resolves a surface defect. Clockwise from upper left: the real part showing surface defects; the motion-analysis software revealing a matching B-axis error; the predicted result after correcting that error; and the actual post-tuning cut with the defect eliminated. Source: FANUC America

According to Schultz, the typical workflow looks like this:

- A part goes out of compliance. Finish defects, chatter-like marks, accuracy drift or variances show up during cutting.

- The issue is diagnosed. Motion-analysis tools determine whether the root cause is mechanical, programming-related or actually inside the servo control loop.

- If results show that tuning is the correct fix, a technician runs the tuning routine, which sends test commands into the axis, reads position-feedback signals and proposes optimal values.

- The technician approves and saves the results. No trial-and-error loops, manual manipulation of gain values or magic spells required.

Schultz says that under the hood, the algorithm relies on encoder or scale feedback and a pre-trained model built from years of servo-system experience. This is not generative AI, he says, and it does not update parameters autonomously while cutting.

Rather, it is a guided setup tool that is fast, consistent and grounded in real machine data. As Schultz puts it, “AI Servo Tuning isn’t an ‘AI black box’ technology,’ it just turns years of servo-tuning experience into a repeatable process.”

It’s worth pointing out that this general direction isn’t unique to a single brand. Their functions vary, as do their naming conventions, levels of automation and target users. Regardless, the industry trend is clear: servo expertise is being captured in software so more machines start out tuned correctly and recover faster after mechanical changes.

Where Machining Improves

When servo behavior is the root cause of a machining defect — and Schultz sees this all the time — AI-assisted tuning addresses it immediately. It can eliminate servo-related marks that appear only in certain toolpath regions. One critical result is reduced troubleshooting time: Instead of hours or days of trial and error, the machine can return to productive cutting in minutes. The technology also means that the variance between two machines of the same make and model — but which may have been tuned by different engineers with different approaches — can be reduced greatly.

Rotary axes in particular show big improvements when tuned for contouring rather than positional work alone. As an example, Schultz points to a small five-axis machine that was producing excellent positional work but poor finish quality in certain areas of a contoured part. Motion analysis revealed that the rotary axis was under-tuned. Running AI Servo Tuning only on that axis immediately eliminated the defect and brought the part into compliance with no manual intervention. “When the root cause of a finish or contour problem really is the servo system,” he says, “the tuning routine has done a pretty good job of eliminating those marks immediately.”

A Hidden Opportunity: Variable Load Applications

Schultz says there is one more benefit that many shops haven’t exploited. Some parts — particularly large aerospace components — begin as extremely heavy blanks and end as relatively light structures. This drastic weight reduction during the machining process meant that engineers had to manually create multiple tuning profiles for different workpiece masses. This process can take days.

Now, Schultz says, with AI-assisted tuning a technician can:

- Mount the heavy workpiece, tune the machine and save the profile.

- Remove material, tune again and save a second profile.

- Switch between these profiles during production based on the machine’s current load.

“Instead of trying to live with one baseline tuning for everything, you can very quickly generate and save profiles for different conditions,” Schultz says. “That’s a big deal on machines where the mass changes a lot across the cut.”

In this case, AI is not giving shops a brand-new capability; it is enabling a level of performance that previously required servo-tuning expertise to achieve.

What the System Doesn’t Do

Schultz also set clear boundaries around the limits of this technology as it exists today:

- It is not an always-running, self-optimizing AI system.

- It does not make live parameter changes during machining.

- It is not a cure-all for every finish or accuracy problem.

To that last point, if chatter or marks are caused by tooling, workholding, programming or mechanical issues, AI servo tuning will not disguise the problem — nor is it meant to.

The people who build, retrofit and service machines will be the ones using this feature, not the operators or programmers running day-to-day work. But if AI in machining sometimes feels abstract , this is a focused application of machine intelligence that makes motion control faster, more consistent and more predictable. Schultz himself is the first to point out that it is not autonomous machining, but it is also not a hyped-up version of artificial intelligence. AI servo tuning is simply a quiet improvement that shows up in the cut.

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreLegacy After Loss: Writing the Next Chapter of a Family-Owned Machine Shop

When a beloved machinist’s passing left his shop in his children’s hands, the three siblings stepped up, transforming the business to honor his legacy and build a new future.

Read MoreSolidCAM iMachining and Technology Wizard: Faster Machining and Longer Tool Life

Smarter toolpaths to tackle modern machining challenges.

Read More