Adapting to Aerospace Change

The changing demands of aerospace companies have prompted machine shops such as this one to evolve their processes and equipment to become more competitive.

Share

CNC Industries is a machine shop that has successfully served aerospace customers for a number of years. In fact, this market represents more than 50 percent of the work that currently flows through the Fort Wayne, Indiana business.

That said, it is becoming more challenging to serve that industry, explains Steven Deam Jr., CNC Industries’ CFO and IT manager. Previously, aerospace companies were effectively content simply to find shops with the capability to machine their complex components. In just the last few years, however, there’s been a big push on pricing, Mr. Deam notes, largely because there are a greater number of shops that now can perform this type of work. At the same time, aerospace companies have cut batch sizes quite a bit as they continue the transition to JIT production. In some cases, they have divested their operations of in-house manufacturing capacity altogether, adopting a “design and integration” model in which they rely on suppliers to engineer the process to produce the parts and/or sub-assemblies they need.

Such challenges have spurred CNC Industries to make fundamental changes to minimize its production costs as well as think hard about the types of additional changes it should embrace to be more competitive down the road. I found it interesting to learn more about not only what they’ve already done, but what they plan to do in this regard.

Some of the shop’s recent efforts to become more efficient and effective at serving aerospace customers include:

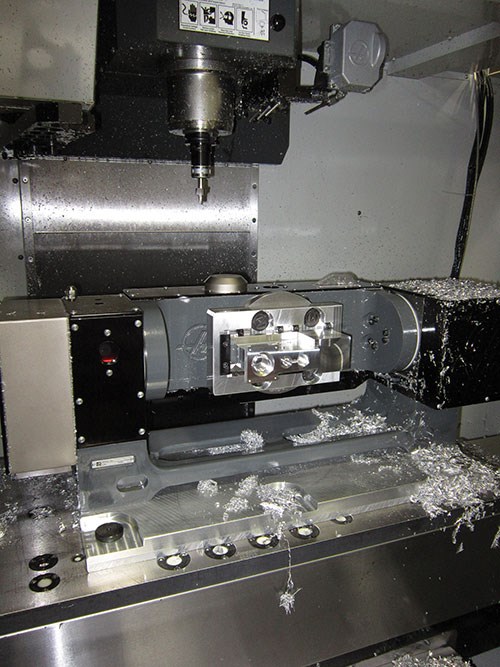

• Integrating four- and five-axis machining—Last year, the shop began moving away from three-axis work to take advantage of the benefits that four- and five-axis machining offer. Rather than purchasing new five-axis machines, it added three Haas rotary tables that can be used on a variety of its existing VF machines. These rotary tables feature large-diameter, aluminum-bronze worm gear meshing with a ground steel worm hardened to 60 HRc. According to the manufacturer, indexing accuracy is realized because a table’s worm gear is cut while it’s attached to the spindle, rather than assembling the finished worm gear to the spindle. Each assembled spindle is individually trammed-in on a CNC gear hobber to no more than 2-microns runout, and then the worm gear is precision-cut to ensure concentricity between the large-diameter ball bearings and the worm gear.

Mr. Deam says the prime advantage of four- and five-axis machining using these rotary tables is that it greatly reduces the amount of part handling that was previously required for three-axis operations. It’s no longer economical to pay an operator to simply load and unload parts all day on a three-axis machine. Now, it’s possible to chain operations together on one machine, which means employees touch parts less frequently and are often able to tend multiple machines. This also greatly cuts down on the amount of stock and work-in-process that was previously staged at machines.

A relatively simple block part is a good example of how the shop takes advantage of multi-axis processes. The small aluminum block requires just a few holes to be machined in all six sides, and machining time for each side is approximately one or two minutes. Previously, an operator loaded part after part on a three-axis machine. Now, a fourth-axis rotary table enables an operator to load eight parts at once and have the machine complete them all in 3.5 hours before reloading the machine with a fresh batch of parts.

Of course, four- and five-axis work requires different programming considerations compared to three-axis machining. For example, Dustin Kimbrell, plant manager, says programmers must keep in mind that even small adjustments such as work shifts affect the rotary as well as the linear axes. That’s why for applications such as the part shown above, it makes sense for programmers to assign the centerline of the A-axis table as a common zero position so that this zero position doesn’t change as the table rotates.

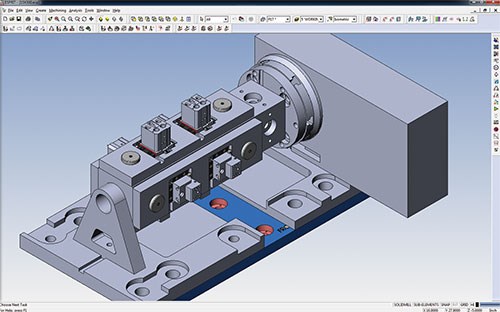

Multi-axis machining in one setup is also helpful in maintaining feature-to-feature accuracy of complex parts. The aircraft wing component shown on the previous page was a good candidate for four-axis machining because none of its surfaces is normal to the others. Positioning in four axes enabled its four sides to be machined in one setup. However, this part was especially challenging because the shop was not given a 3D solid model. Instead, the customer provided lofted data (essentially cross-sectional curve data) from which the shop had to create the part model. But because it uses Solidworks to create such models, it was able to directly import the model into its recently purchased Esprit CAM package from DP Technology to create tool paths.

• Switching to 3D CAM—The shop’s new Esprit CAM package with four- and five-axis modules replaces its previous 2D CAM software. Mr. Deam says Esprit offers a number of benefits for the type of complex work the shop is performing beyond the ability to directly import Solidworks models. Unlike its previous CAM software, Esprit takes advantage of the shop’s quad-core computers to greatly reduce program calculation time. For example, when a tool change was made using the previous CAM software, program reprocessing could take as long as 2.5 hours. By taking advantage of quad-core computing capabilities, reprocessing time for such a change now takes just a matter of minutes.

CNC Industries also appreciates the improved simulation capabilities that Esprit offers. This is especially important in ensuring there will be no collisions during the more complex four- and five-axis work the shop is now performing. Mr. Deam also notes that the Esprit reseller, Midwest CAM, has been helpful in providing postprocessers as the shop continues to reprogram existing three-axis jobs to be run on four- and five-axis equipment.

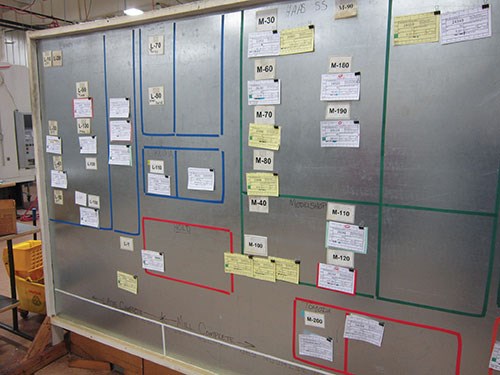

• Continually Improving its ERP system—Mr. Deam has a BS degree in computer science. In 1997, he began development of a custom distributed ERP system for the shop called JobManager. He used Microsoft Visual Basic to program the SQL-server-based system, which offers the flexibility to be tailored to the shop’s current and future needs. Its interface was designed to be sufficiently intuitive so that employees possessing any level of computer experience would be able to comfortably navigate through the system and quickly locate the information they need. There are a total of 50 computer workstations throughout the shop, (one is located at every CNC machine). Only one or two mouse clicks are required to access necessary documents or data at any computer station, he says.

The main operator interface lists critical information such as job number, drawing number, batch size, inventory level and operation sequence. Operators can click to view documents including drawings, setup instructions, setup photos, inspection reports and tool lists for any job. The interface includes an electronic time card that keeps tabs on time devoted to running different jobs. In the past, a large stack of paper time cards would be delivered to the office each day to be keyed into the system. Now that data is automatically uploaded by operators at the end of their shifts.

Currently in its second version, JobManager II facilitates accurate quoting, ordering, scheduling, process flow, inspection, corrective actions and inspection, as well as dozens of other functions. It has been modified per the shop’s recent AS9100 certification in 2010, which requires additional documentation and accountability. (In 2011, the company passed its audit to AS9100 Rev. C. while it was re-assessed to the ISO 9001-2008 standard.) Plus, CNC Industries continues to make improvements to the system. For example, it now uses JobManager II to perform deep analytics to better understand the true cost of machining any given part. Mr. Deam says this enables the shop to generate more accurate quotes while providing a good account of exactly what transpired during each completed job.

• Providing additional training—CNC Industries is stepping up its training efforts for programmers and shopfloor employees alike. Training for programmers is mandatory, and the shop frequently hosts DP Technology representatives to help the engineering staff become more adroit at developing four- and five-axis programs. For shopfloor employees, CNC Industries now offers access to Tooling U online courses chosen to match the type of work that the shop typically performs. In the past, the shop would reimburse employees who completed job-related training courses. Now, employees can use company computers to access the pre-paid Tooling U courses after hours.

Moving Forward

As a small shop with 50 employees, CNC Industries hadn’t thought that cellular manufacturing would be appropriate given the mix of work it performs. That said, it is in the early planning stages of developing machining cells for common part families. For now, it is structuring cells around existing machine locations, focusing on how best to shift management and shopfloor employee responsibilities around a cell production strategy. Machines will be physically moved and configured into cells once an effective process has been established. In addition, the ERP system will be modified because some jobs now will be assigned to a cell possibly having multiple machines and operators instead of an individual operator.

CNC Industries is also considering adding larger machines including HMCs to accommodate bigger workpieces. It has recently completed what Mr. Deam calls a speculative expansion that added 25,000 square feet of floor space to its existing 30,000-square-foot facility. At the moment, the shop doesn’t have contracts that would require new machines for that space, so he jokingly calls the new area a really expensive storage facility. However, the expansion provides the flexibility to bring in new, perhaps larger equipment and best configure it to meet future demand.

Finally, it is rethinking its customer base. Although the shop has traditionally had one or two prime customers at any given time, it has established a goal to limit any one customer to no more than 20 percent of its total sales. This will enable the shop to better weather the cyclical nature of the business, which is especially daunting when a shop is effectively beholden to one customer. It is also looking to expand into different industries to become more diversified. For example, it is going after more government- and defense-related work. The shop has also recently produced parts for a variety of niche markets including high-end, limited-edition motorcycles and sporting goods accessories. In the end, the equipment and process changes spurred largely due to the challenges serving the aerospace market will put CNC Industries in a more competitive position to win complex work in these other industries, too.

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreAutomation is for Everyone

Not just for large shops, automation can help even the smallest shops solve labor challenges and become more profitable and efficient.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More