Share

This content originally appeared in our sister brand, Production Machining. For more insights and information about precision machining, visit productionmachining.com.

In machine shops across the globe, there is a definite trend toward implementing multitasking machines for the purpose of completing parts on one piece of equipment. This efficient machining process eliminates the need to run parts across multiple machines, which saves equipment floor space, setup time and labor.

Fuji Machine America Corp., a creator of automated machine tools, combines the machining and robot experience to present a new automated multitasking machining solution with an integrated robot.

“Any shop that can benefit from product completion in one machine is the ideal candidate for the Gyroflex,” says Frank Tortorich, vice president of sales and service at Fuji Machine America. He explains that the machine handles the process from the beginning with the raw material, all the way through to a finished part, including measuring and testing for quality.

By using Fuji automation, the Gyroflex offers the size, rigidity and productivity necessary to handle simple to complex workpieces. Photo Credits: Fuji Machine America Corp.

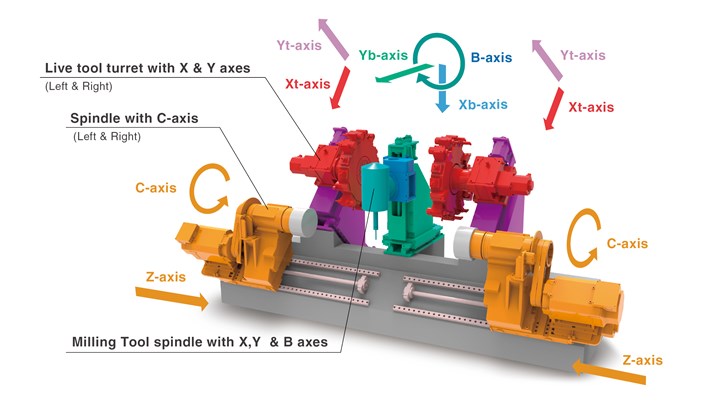

The machine’s dual-opposed main spindles for simultaneous operation, a B-axis milling tool spindle, multiple workflows, tooling capacity, integrated automation, and rigidity are among the key features of the Gyroflex.

Dual-opposed spindles. The machine’s opposed twin spindles positioned on Z-axis slideways are equal in size and machining capability. They can perform the same operations (op-10a/10b) or can pass a part from the first spindle to the second while maintaining positioning accuracy, thereby performing op-10 and op-20. If the application calls for two separate operations, a partition inside the machine is used to create two separate workzones. Also, the Z-axis slide can move at high speeds to reduce loading time to the second spindle.

B-axis milling spindle. The B-axis milling spindle is mounted on rigid X- and Y-axis boxway slides. The spindle accesses the two Z-axis spindles and swings up to 190 degrees, enabling different types of operations, including turning, drilling and part probing. Further, the B axis and the tool are clamped by curvic coupling, resulting in accurate index location with the turret precisely centered, according to the company. Gyroflex also comes standard with Sandvik Coromant Capto C6 toolholder interfaces, which provide virtually unlimited combinations of tooling for all different types of applications, Tortorich explains.

The machine’s opposed twin spindles positioned on Z-axis slideways are equal in size and machining capability. The B-axis milling spindle is mounted on rigid X- and Y-axis boxway slides. The spindle accesses the two Z-axis spindles and swings up to 190 degrees, enabling different types of operations, including turning, drilling and part probing. Further, the B axis and the tool are clamped by curvic coupling.

Multiple workflows. Various workflows are accommodated on this machine, depending on the needs of the machine shop. Left to left, right to right, left to right and right to left are all available. The company says the machine’s multiple workflows enable flexible part processing and reduced setup/changeover times.

Tooling capacity. Both live tool turrets hold 15 tools, while the automatic tool changer (ATC) — located at the top of the machine — holds 40 tools. The ATC holds multiples of the same tool for low-mix, high-volume applications where a tool might break or wear and need replacement. And, for high-mix, low-volume applications, it can hold many different types of tools for quick tool replacement.

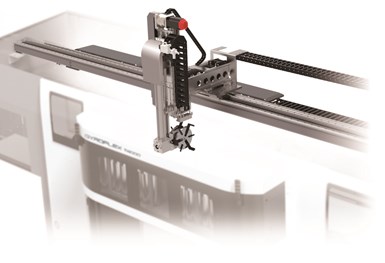

Fuji’s three-axis gantry robot for parts handling accesses peripheral devices at the left and right sides of the machine.

Integrated automation. The company’s own three-axis gantry robot is integrated in the machine for unattended parts handling. The robot’s two arms — primary and secondary — access peripheral devices at the left and right sides of the machine, the company says.

The hydraulic robot chuck enables stable clamping and workpiece handling with minimum space requirements. The thin-type, double-hand design, according to Tortorich, offers flexibility and easy setup of workpieces as well as handling that requires minimum space.

The company offers an optional robot chuck clamp confirmation sensor on the Gyroflex. This is said to ensure that the workpiece is clamped properly in the robot hand before loading or unloading the machine for a smooth and quick automation transfer process.

Rigidity. This machine is extremely rigid with a solid one-piece casting base design and box ways for both turrets, and X-, Y- and B-axis slideways, the company says.

Fuji Machine America Corp. | fujimachine.com

Related Content

Controlling Extreme Cutting Conditions in Large-Part Machining

Newly patented technologies for controlling chatter and vibration during milling, turning and boring operations promise to drastically reduce production time and increase machining performance.

Read MoreMazak Achieves Production Milestone, Announces Plans to Open New Technical Center

Mazak Corporation celebrates the completion of its 40,000th machine at the Mazak iSmart Factory in Florence, Kentucky, showcasing advanced manufacturing and digital integration.

Read MoreMaximizing Milling Operations With the Right Cutter

Selecting milling cutters that are suited to the task at hand can reduce cycle times, improve part quality and save money. Here’s where three milling cutters excel.

Read MoreSoft Skills Prove a Sharp Edge in Plastics Manufacturing

East Coast Precision Manufacturing’s uncommon specialties attract many customers — but its prompt, earnest communication strategy is what wins it repeat business.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More