Bringing It All Together

Shops that serve medical instrument and implant manufacturers face special challenges. Their customers typically want precisely machined parts plus the extras such as finishing, marking, assembly and expert handling of the regulatory paperwork. That’s why this shop is focused on providing more than just the machining.

Share

It’s a given that shops serving medical-industry customers must possess advanced machining capabilities. Of course the same could be said for shops supplying complex components to myriad other industries. What seems to separate the “medical” shops from others is the holistic approach many take to become one-stop suppliers to the medical market. That type of approach was clearly evident during a visit to Mark Two Engineering (www.marktwo.com), a shop founded by medical-industry veterans to meet the evolving needs of surgical instrument and implant manufacturers.

The Miami, Florida shop demonstrates its total-manufacturing approach in these fundamental ways.

The shop offers various part-production options. Mark Two Engineering’s facilities house multi-axis VMCs; live-tool turning centers; Swiss-type lathes; wire and ram EDM units; and plastic and metal injection molding machines. In addition, the shop recently implemented a rapid manufacturing process it calls “4th Dimension Technology,” which combines advanced rapid prototyping equipment with a proprietary investment casting technique to quickly create intricate components from a CAD model in virtually any castable metal. These numerous part-production capabilities allow the shop to offer its customers—some of which have no manufacturing knowledge—many different options for creating their components.

The shop has many non-machining, secondary manufacturing processes under its roof. Because medical components often require finishing operations, the shop has integrated precision cleaning, tumbling, media blasting, electropolishing, anodizing, passivation, laser etching, heat treating and other related processes. These in-house capabilities give the shop better control over those operations and enable faster turn-around to its customers.

The shop provides more than just component production. The dental-implant guidance kits the technician is handling on the cover of the magazine exemplify the shop’s push to be more than just a supplier of precision parts. In addition to machining and performing all secondary operations for the kits’ titanium components, the shop machines and laser-marks the plastic part trays and assembles the kits in a clean room. This minimizes the number of vendors its customer must use to produce the kits.

The shop operates under regulatory procedures in a disciplined manner. All of Mark Two Engineering’s employees are trained to be mindful of the policies and procedures required to remain compliant with the Food and Drug Administration’s (FDA) good-manufacturing practices. This mindset must be shared by everyone from the quality department to the building’s cleaning crew, because there are numerous ways these regulations can cause a shop to trip up. And non-compliance can be costly to shops in many respects.

Interestingly enough, it’s this painstaking attention to process detail that precludes Mark Two Engineering from taking on all types of work. The amount and strict management of documentation required in the production of medical components adds overhead to the manufacturing process. So most of the time, the shop can’t be competitive on relatively straightforward machining work because those jobs must be held to the same documentation requirements as any intricate medical job. This isn’t a dilemma, however, because the medical components produced by shops such as Mark Two Engineering will continue to be in high demand no matter how erratic economic conditions might be.

Bill Box and Greg Murphy are two of the shop’s three founders. These two men, in addition to Scott Whitten, vice president of manufacturing, highlight the challenges of being a successful supplier to the medical industry and offer examples of how their shop provides customers with more than just machining services.

Focused On Medical From The Start

Mr. Box and Mr. Murphy have a combined 55 years in the medical manufacturing industry. They started Mark Two Engineering in 1996 with the sole purpose of providing R&D/prototyping services to surgical implant and device manufacturers. At that time, they had no intention of going after production work.

After a year and a half, the founders realized that they needed to take on production work in order to subsidize their passion for helping customers develop new medical solutions. That’s why they added CNC equipment and expanded into a number of additional bays in their Miami facility over the years. Today, approximately 80 percent of the shop’s work is for large medical manufacturers and small “incubator” companies. These incubator companies, whose numbers are rising, consist of medical-device entrepreneurs that lack the machining capabilities to produce components and assemblies for designs they hope to sell to the big medical manufacturers. Difficult aerospace and automotive jobs account for much of the shop’s remaining production work.

The shop holds an ISO 9001:2000 certification and is compliant with the FDA, the FAA and ISO 13485:2003. The ISO 13485:2003 quality-management standard shows potential customers that the shop has the ability to provide devices and related services that consistently meet medical and regulatory requirements.

These quality systems require Mark Two Engineering to create and maintain a master traveler packet for every lot of parts it creates and ships to customers. Each traveler provides complete traceability of all components to verify that every step, from material receiving and tagging to final part inspection, is carried out to the letter. The traveler originates in the shop’s documentation department before a job is sent to the shop floor. It then goes to the tool crib so an attendant can pull the proper tools and deliver them to the specified machine tool. When the tools and traveler arrive at the machine tool, the operator has to verify the material lot numbers and set up the machine per the detailed instructions. There can be no variation from the setup instructions.

The traveler’s part inspection sheets must be maintained in a similar manner. These sheets are comprehensive and lengthy, describing exactly how an inspector must check various part features and what measuring devices should be used. Inspectors must document the device’s control number and list the date of its last calibration. Keeping measuring devices properly calibrated is critical. If an FDA inspector were to find out that a part lot was measured with a device that was not calibrated, the shop would have to re-measure every part to prove that they were actually machined to specification. That’s why every measuring device in the shop has a sticker with a calibration date on it. Each day, an employee walks the shop floor, collects devices scheduled for calibration and returns them after they are calibrated.

Per FDA regulations, the job travelers for every lot the shop ships must be stored and accessible for a minimum of 7 years. To give you a sense of the sheer volume of documentation that shops like this must maintain, Mark Two Engineering has a 12-by-40-foot bay filled to the brim with past job travelers. (That’s a healthy amount of floor space that’s not making the shop any money.) The FDA has been slow to adopt digital documentation procedures. However, once the FDA okays the use of digital documentation, the shop will certainly switch to a more convenient paperless process.

Bringing Processes Together

The shop continues to add to its wealth of internal manufacturing capabilities as needs arise. Having nearly all requisite processes in-house and performed by trained shop personnel not only allows quicker deliveries to customers, but also helps ensure that the documentation is properly maintained for every job.

A dental implant guidance kit the shop creates is an excellent example of how it uses its multiple processes to provide a solution—not just a machined part—for one of its customers. The shop machines, cleans, anodizes and laser-marks the kit’s blades and pins. In addition, it machines the kit’s tray from plastic stock and laser-marks key component size information on it. The kits are assembled by technicians in the shop’s Class-100,000 clean room. The completed kits are then packaged and sent to the customer, where each is repackaged as part of a complete product offering to dental surgeons. The shop currently produces approximately 100 of these kits per month.

The shop’s clean room maintains the air quality, temperature and humidity required to protect components against contamination. The air in the clean room is continually filtered to remove dust particles and other airborne impurities. A Class-100,000 rating means the environment contains no more than 100,000 particles larger than 0.5 microns per cubic foot of air. Shop employees who work in the clean room must wear lint-free, anti-static, protective suits (often called “bunny suits”) that prevent human skin and hair particles from entering the environment. To ensure customer product secrecy, the room’s opaque curtains can be drawn to prevent visitors from viewing products as they are handled.

Yet Another “Non-Machining” Process

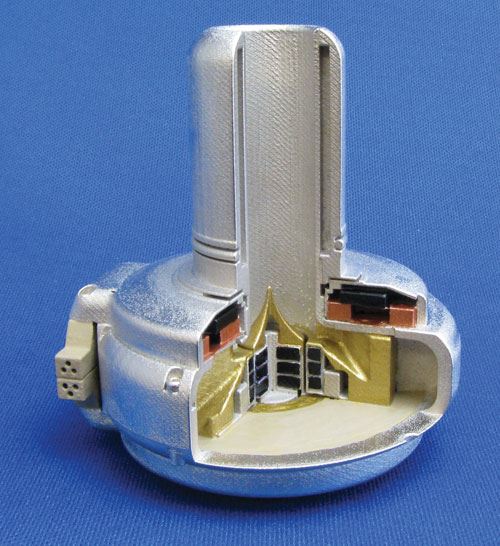

Mark Two Engineering recently began offering its 4th Dimension Technology rapid-manufacturing process as an alternate method to produce intricate parts. (The “fourth dimension” is time, alluding to the potential for reduced overall manufacturing time). This investment casting process, which requires little or no secondary machining, allows the shop to produce a completed part in the customer’s specified metal from a CAD file in a matter of days.

Investment casting, also known as lost-wax casting, has been around for thousands of years. In fact, it’s the most common way jewelry is produced. Traditionally, a mold is created from a master part model. That mold is used to produce wax patterns that receive gates and sprues, and then are attached to a wax tree that will eventually provide paths for molten casting metal to flow. The completed tree is packed in investment and melted away in a kiln, leaving the tree’s impression behind in the investment mold. Molten metal is then poured into that cavity to create the tree and parts. Once cooled, the metal tree is removed from the investment mold, and the parts are picked off the tree for subsequent finishing operations.

The shop has many years of experience with investment casting and has a foundry located down the street from its main facility. While similar to the conventional investment casting process, Mark Two Engineering’s method does not require a master mold to create wax part patterns. Instead, the shop uses a Pro Jet HD 3000 3D printer from 3D Systems (Rock Hill, South Carolina) to create the wax patterns layer-by-layer.

The process starts with a CAD model of the customer’s part saved in the three-dimensional STL file format. This is the de facto standard data transmission format for stereolithography, and is supported by a variety of CAD packages (Mark Two Engineering primarily uses Pro/Engineer and SolidWorks). A shop engineer adds gates and sprues to the CAD model, compensates for shrinkage and downloads the file to the 3D printer. The printer uses two types of wax when producing patterns: a blue build wax forms the actual pattern; a white support wax braces pattern features during printing. Once printing is completed, the dissolvable support wax is removed from the build wax, leaving behind the completed pattern. Typical wax-pattern accuracy ranges from 0.001 to 0.002 inch per inch of part dimension. When used in extreme-high-definition mode, the printer creates layers that are only 16 microns thick.

Once the printed sprued patterns are attached to a wax tree, the tree is delivered to the shop’s foundry for investment casting. The casting process accommodates virtually any castable material, including aluminum, cobalt, nickel alloys and stainless, carbon and tool steels. Because of the reactive nature of titanium, the shop hasn’t finalized the casting process for that common medical material. Once it has the titanium casting process nailed, the shop feels it will have a manufacturing game-changer on its hands, especially when it comes to the market for implantable medical components.

While as-cast hole sizes and finishes may be suitable for a customer’s part, holes that must be precisely sized may require a secondary drilling operation. The shop often uses a standard drill press to perform these operations. The parts can also be tumbled to improve their surface appearance.

The 4th Dimension Technology, a process that Mark Two Engineering is considering licensing, makes design changes easy and affordable because each design iteration doesn’t require a new master wax mold. This process is best suited for prototypes and small batches of complex parts that require fast turnaround. For bigger production runs, it may be more cost effective to use the shop’s conventional machining centers or Swiss-type lathes.

Exciting Times

The prospects for the 4th Dimension Technology excite the shop, as it provides not only another manufacturing option for medical customers, but also an opportunity to branch out into other industries. However, the vast majority of the shop’s income has and will continue to come from conventional machining processes. That’s why the shop is grouping key machines together to improve workflow and standardizing its conventional machining processes to speed setups. For example, all VMCs will eventually use 2-by-2-inch grid fixturing plates from Carr Lane Roemheld for quick workholding device positioning and attachment. Each hole in the plates is topped with a steel locating bushing and has threads below the bushing to accept fasteners. In addition, Midaco pallet changers such as the one shown above will be installed on all VMCs. This will not only speed job changeovers, but also allow the shop to run jobs on virtually any machine that’s available.

Another reason these are exciting times at Mark Two Engineering is because the shop is in a transitional period. Mr. Box’s daughter Cheryl has recently been appointed company president, and Mr. Murphy’s daughter Nicolle now heads the sales and marketing department. The men are optimistic about the future of the company because this next generation brings enthusiasm as well as an appreciation for what can be accomplished with the latest manufacturing technologies. Doors to new opportunities are sure to open for this shop in the years to come.

Related Content

Vertical Integration, Automation Helping 3D Printed Spine Implant Manufacturer Scale Production

How did a leading spine implant manufacturer leverage 3D printing to compete on cost with CNC machining? Learn how advanced additive manufacturing techniques are redefining material efficiency and geometric complexity in medical devices.

Read MoreFive-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

Read MoreKyzen Solvents Provide Ease of Cleaning for Medical Parts

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Read MoreThe Four Phases of a Manufacturer’s Automation Evolution

With more and more automation options available for manufacturers, how do shops figure out what works best? Medical manufacturer rms Company has acquired robot arms, AGVs, pallet changers and software, and while it has found success with all, it has learned how some solutions meet its particular needs better than others.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More